Loom Tubing Split Techniques for Efficient Fabrication and Design Solutions

Understanding Loom Tubing Splits A Guide to Effective Use and Applications

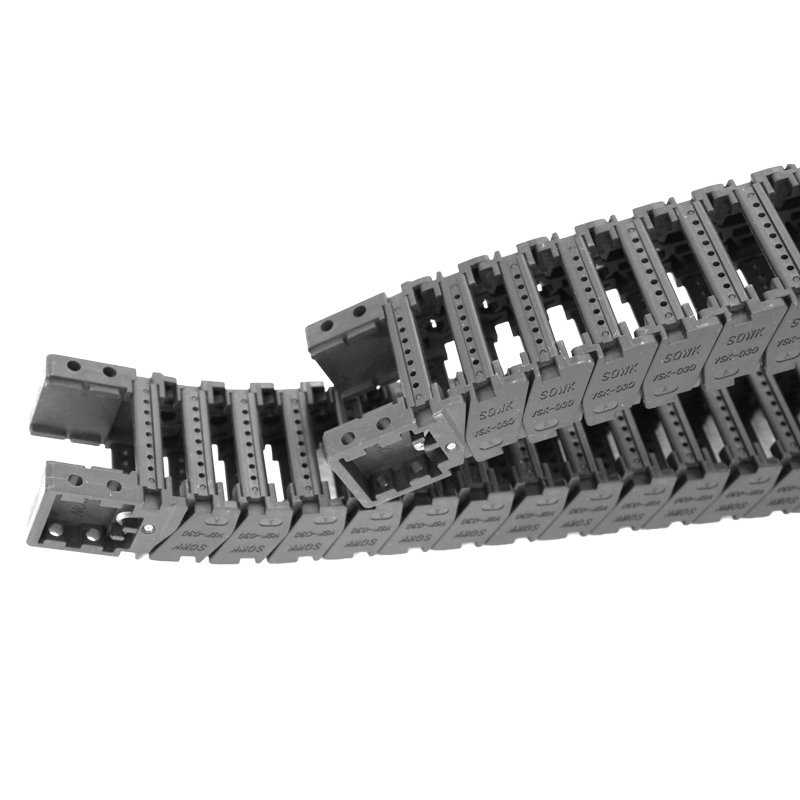

Loom tubing has become an essential component in various industries, including manufacturing, automotive, and aerospace. Its versatility and ability to protect and organize wires and cables make it a popular choice among engineers and technicians. One of the specific terms that arise in discussions about loom tubing is tubing split. In this article, we will explore what loom tubing splits are, their applications, benefits, and considerations for effective use.

What is Loom Tubing?

First, it’s important to understand what loom tubing is. Loom tubing is a type of protective conduit made from flexible materials such as nylon, polyethylene, or PVC. It is designed to encase wires and cables, shielding them from physical damage, abrasion, chemicals, and UV exposure. Loom tubing is available in various diameters and colors, allowing for customization based on the specific requirements of different applications.

Defining Tubing Split

A “tubing split” refers to the feature of loom tubing that allows it to open up along its length, creating a seam that can be easily split apart. This design facilitates the entry and exit of wires and cables at different points without needing to cut the entire length of the tubing. The tubing can be split to accommodate multiple cables running through a single conduit, making it an ideal solution for complex wiring environments.

Applications of Loom Tubing Splits

1. Automotive Industry In automobiles, loom tubing splits can organize and protect the numerous wires that connect various electronic components. For instance, a split loom allows technicians to route power, signal, and ground wires through a single protective tubing, ensuring they are well-organized and less susceptible to wear and tear.

2. Electrical Installations In residential and commercial electrical work, loom tubings with splits can simplify wiring installations. Electricians can split the tubing at junction points, allowing them to branch off to different devices and lights while maintaining protection and organization.

3. Consumer Electronics In consumer electronics such as computers and televisions, loom tubing splits offer a neat and efficient way to manage the often chaotic cabling associated with multiple components. This not only improves aesthetics but also enhances airflow and cooling, which is vital for performance.

4. Industrial Applications In industrial settings, loom tubing splits help manage the cables of machinery and equipment, reducing the risks of entanglement and potential damage. A split design allows for easy maintenance and adjustments as machinery configurations change.

loom tubing split

Benefits of Using Loom Tubing Splits

- Flexibility One of the biggest advantages of using split loom tubing is its flexibility. Users can easily route cables in any desired direction, accommodating tight spaces or complicated layouts.

- Protection Split loom tubing provides excellent protection against abrasion and environmental factors. This durability can extend the life of the cables inside, which can reduce downtime and maintenance costs.

- Organization With a split design, technicians can keep multiple wires organized, making it easier to identify and troubleshoot issues in complex wiring systems.

- Ease of Use The ability to split the tubing means less time is needed for installation. Technicians can quickly add or remove cables as needed without needing to replace the entire loom tube.

Considerations for Effective Use

While loom tubing splits offer numerous benefits, there are some considerations to keep in mind

1. Size Selection Choosing the correct diameter of loom tubing is crucial. If the tubing is too large, wires may become loose and unorganized. If it’s too small, it can lead to excessive strain on the cables, causing damage.

2. Temperature Ratings Different materials have different temperature ratings. It’s important to select loom tubing that can withstand the environmental conditions it will be exposed to, especially in industrial settings where heat and chemicals may be a concern.

3. Installation Proper installation is key to maximizing the benefits of loom tubing. Ensure that the tubing is cut evenly, and any entry points for wires are smooth to avoid friction damage.

In conclusion, loom tubing splits are an indispensable tool for organizing and protecting wires and cables in various applications. By understanding their features and benefits, users can make informed choices that enhance efficiency and safety in their wiring projects. Whether in automotive, industrial, or electronic applications, effectively implementing split loom tubing can lead to improved outcomes and longevity of cabling systems.