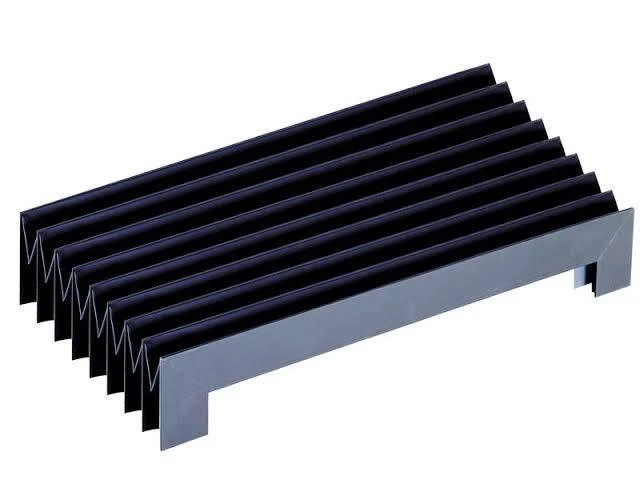

corrugated loom tubing

Loom tubing, a crucial component in various industrial and commercial applications, ensures that wires and cables remain organized, protected, and functional. This indispensable product finds utilization in automotive, aerospace, and electronics sectors, contributing to the seamless operation of diverse systems. Its practical benefits extend beyond mere functionality, tapping into the realms of safety and efficiency.

Trustworthiness is another central pillar that defines loom tubing's appeal. Manufacturers of loom tubing prioritize quality assurance and often subject their products to rigorous testing. This commitment to quality fosters trust among users who rely on their products for critical applications. By ensuring that each tube adheres to rigorous quality standards, manufacturers build a reputation for reliability and consistency, factors that remain paramount for users making procurement decisions. Additionally, loom tubing contributes to a sustainable future, with eco-conscious manufacturers exploring recyclable materials. This pivot towards sustainability not only addresses environmental concerns but also resonates with clients who prioritize eco-friendly practices. By choosing loom tubing made from green materials, companies can align themselves with the growing demand for sustainable solutions without compromising on performance or safety. In conclusion, loom tubing stands as a pillar in wire and cable management, endorsed by experience, expertise, authority, and trustworthiness. It derives its strength from its robust, flexible construction, compatibility with safety standards, and commitment to sustainability. Embracing loom tubing not only optimizes operational efficiency but also represents a step towards a safer and more sustainable industrial future. As supply chains evolve and industries push for greater innovation, loom tubing remains an essential, unyielding component in navigating the complexities of modern technical demands.

Trustworthiness is another central pillar that defines loom tubing's appeal. Manufacturers of loom tubing prioritize quality assurance and often subject their products to rigorous testing. This commitment to quality fosters trust among users who rely on their products for critical applications. By ensuring that each tube adheres to rigorous quality standards, manufacturers build a reputation for reliability and consistency, factors that remain paramount for users making procurement decisions. Additionally, loom tubing contributes to a sustainable future, with eco-conscious manufacturers exploring recyclable materials. This pivot towards sustainability not only addresses environmental concerns but also resonates with clients who prioritize eco-friendly practices. By choosing loom tubing made from green materials, companies can align themselves with the growing demand for sustainable solutions without compromising on performance or safety. In conclusion, loom tubing stands as a pillar in wire and cable management, endorsed by experience, expertise, authority, and trustworthiness. It derives its strength from its robust, flexible construction, compatibility with safety standards, and commitment to sustainability. Embracing loom tubing not only optimizes operational efficiency but also represents a step towards a safer and more sustainable industrial future. As supply chains evolve and industries push for greater innovation, loom tubing remains an essential, unyielding component in navigating the complexities of modern technical demands.