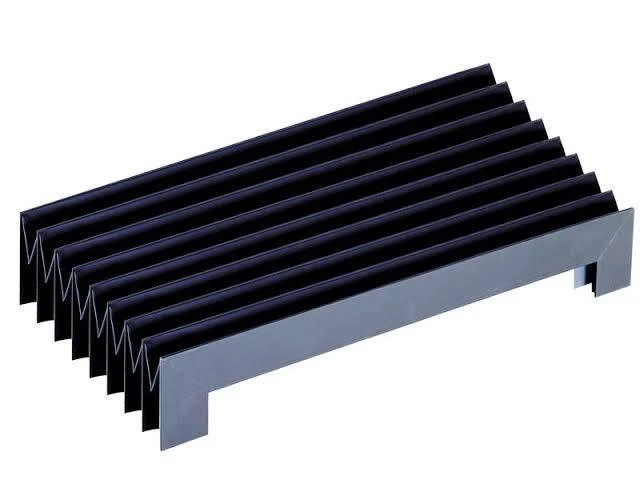

loom tubing

Loom tubing is an essential component in a variety of industries, recognized for its unmatched versatility and reliability in safeguarding wires and hoses. From automotive to aerospace, loom tubing ensures the effective organization and protection of critical components, elevating both performance and safety standards.

Building trust with loom tubing also involves consideration for sustainability. As industries globally move towards eco-friendly practices, so too has the development of loom tubing adapted. Recyclable materials and manufacturing processes aim to minimize environmental impact without compromising quality and durability. By choosing environmentally considerate products, businesses and individual consumers contribute to broader ecological goals while maintaining top-tier operational standards. A professional approach to loom tubing selection also considers installation and maintenance. Professionals advocate for meticulous planning and periodic checks to ensure tubing remains in optimal condition. Businesses incorporating loom tubing are advised to adhere to recommended maintenance schedules, as regular inspections can prevent unforeseen failures and prolong the life of equipment. Ultimately, loom tubing embodies a blend of engineering ingenuity and practical application. Its adoption across diverse fields demonstrates a wide-reaching recognition of its importance. With continued research and development, loom tubing will likely evolve, adapting to future challenges and further solidifying its status as a fundamental component of modern industry. Embracing loom tubing not only secures the functional integrity of vital technological systems but also reflects a commitment to quality, reliability, and environmental stewardship. For those invested in the future of their industries, understanding and utilizing loom tubing is not merely a choice—it's an imperative.

Building trust with loom tubing also involves consideration for sustainability. As industries globally move towards eco-friendly practices, so too has the development of loom tubing adapted. Recyclable materials and manufacturing processes aim to minimize environmental impact without compromising quality and durability. By choosing environmentally considerate products, businesses and individual consumers contribute to broader ecological goals while maintaining top-tier operational standards. A professional approach to loom tubing selection also considers installation and maintenance. Professionals advocate for meticulous planning and periodic checks to ensure tubing remains in optimal condition. Businesses incorporating loom tubing are advised to adhere to recommended maintenance schedules, as regular inspections can prevent unforeseen failures and prolong the life of equipment. Ultimately, loom tubing embodies a blend of engineering ingenuity and practical application. Its adoption across diverse fields demonstrates a wide-reaching recognition of its importance. With continued research and development, loom tubing will likely evolve, adapting to future challenges and further solidifying its status as a fundamental component of modern industry. Embracing loom tubing not only secures the functional integrity of vital technological systems but also reflects a commitment to quality, reliability, and environmental stewardship. For those invested in the future of their industries, understanding and utilizing loom tubing is not merely a choice—it's an imperative.