Linear Rail Bellow Covers for Enhanced Protection and Durability in Machinery Applications

The Importance of Linear Rail Bellow Covers in Mechanical Systems

In today's advanced manufacturing and automation landscape, linear rails are essential components that enable smooth and precise motion for various machinery and equipment. These linear motion systems find extensive applications in industries such as robotics, CNC machines, and automated assembly lines. While the mechanical composition and quality of linear rails play a critical role in their performance, an often-overlooked element in enhancing their functionality is the bellow cover. This article delves into the significance of linear rail bellow covers, their benefits, and their applications.

What are Linear Rail Bellow Covers?

Linear rail bellow covers are protective coverings designed to shield linear guideways, ball screws, and other essential components of linear motion systems from external contaminants. Typically made from flexible, durable materials such as rubber or polyurethane, these covers fit snugly over the linear rails, providing a barrier against dust, dirt, and debris. Their design allows them to expand and contract while maintaining their protective function, which is crucial for preserving the integrity of the underlying mechanical systems.

Benefits of Linear Rail Bellow Covers

1. Protection from Contaminants One of the primary functions of bellow covers is to protect linear rails from harmful particles that can lead to wear and tear. Contaminants such as dust, chips, and moisture can significantly reduce the lifespan and performance of linear motion systems. By shielding these components, bellow covers help maintain a clean operational environment, contributing to the reliability and longevity of the equipment.

2. Maintenance Reduction Regular maintenance is a necessity in any industrial setting to ensure optimal performance. However, the wear resulting from contamination often leads to increased maintenance requirements. Bellow covers minimize the frequency and intensity of maintenance needed by keeping linear rails clean and protected. This not only reduces downtime but also lowers the overall cost of ownership for the machinery.

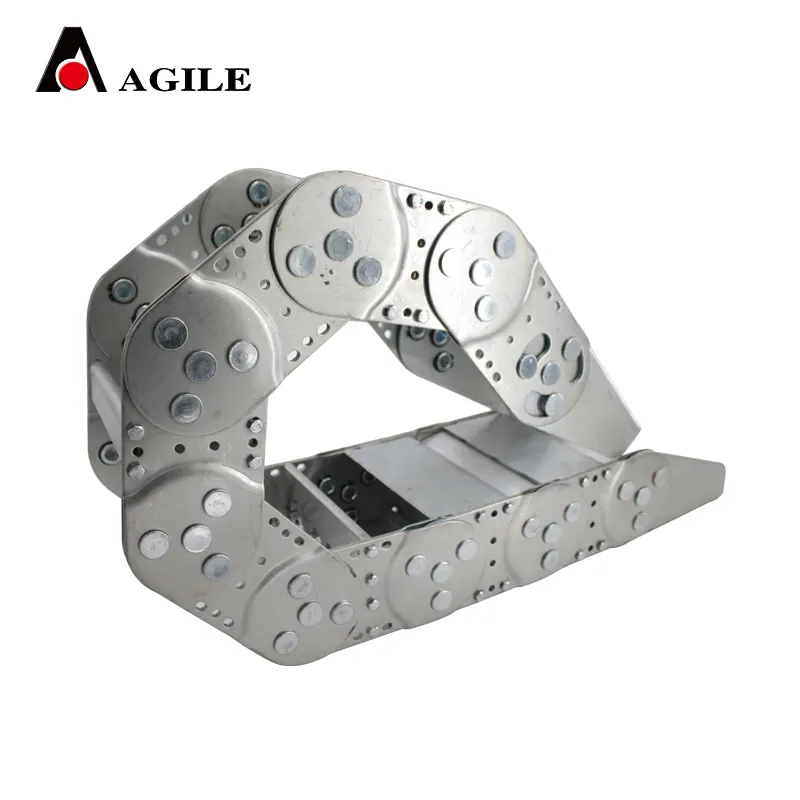

linear rail bellow cover

3. Enhanced Performance Linear motion systems require precision for effective performance. Contaminants can introduce friction and misalignment, leading to decreased accuracy and efficiency. Bellow covers play a vital role in maintaining the precise movement of bearings and rails by preventing foreign particles from affecting their operation. This enhances the machine's overall performance, ensuring a smoother and more efficient operation.

4. Temperature Regulation In some applications, temperature fluctuations can adversely affect the performance of linear motion systems. Bellow covers can provide an extra layer of thermal insulation, helping to regulate the temperature of the components underneath. This is particularly important in high-speed applications where components may experience significant heat generation due to friction.

5. Customization and Versatility Linear rail bellow covers come in various shapes and sizes, allowing for customization to suit specific applications. Manufacturers can design bellow covers to fit different types of linear rails and motion systems, ensuring optimal protection regardless of the machinery's configuration. This versatility makes them suitable for a wide range of industrial applications.

Applications of Linear Rail Bellow Covers

The applications of linear rail bellow covers are vast and varied. In the manufacturing sector, they are commonly found in CNC machines, pick and place robots, and factory automation equipment. They are also utilized in medical devices where precision and cleanliness are paramount, such as robotic surgical systems and laboratory equipment. Additionally, industries that operate in harsh environments, such as construction and mining, benefit greatly from the protective qualities of bellow covers, ensuring machinery remains functional under challenging conditions.

Conclusion

In conclusion, linear rail bellow covers are an indispensable component of modern mechanical systems, serving a vital role in protecting linear motion components from contaminants, thereby enhancing performance and reducing maintenance needs. As industries increasingly move towards automation and precision engineering, the importance of such protective measures will only continue to grow. By investing in high-quality bellow covers, manufacturers can ensure their equipment operates efficiently, reliably, and with a longer service life, ultimately driving productivity and success in an ever-evolving technological landscape.