lathe bellow cover

Understanding the Importance of Lathe Bellow Covers

Lathe bellow covers are vital components in various machinery, particularly lathes, which are widely used in manufacturing and machining processes. These protective coverings serve several critical functions that ensure the machinery operates smoothly, maintains precision, and enjoys a prolonged lifespan. In this article, we will explore what lathe bellow covers are, their functions, benefits, and the factors to consider when selecting them for your equipment.

What is a Lathe Bellow Cover?

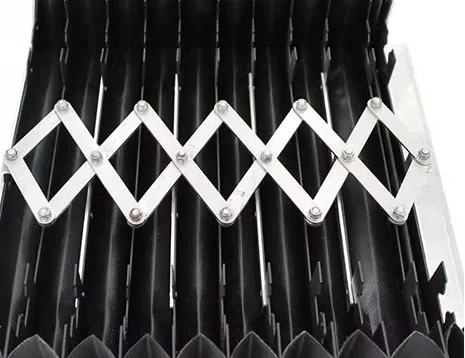

Lathe bellow covers, often referred to simply as bellows, are flexible, expandable coverings that encase the moving parts of a lathe. Typically made from materials like rubber, PVC, or polyester, these covers are designed to protect sensitive components from debris, coolant, chips, dust, and other potential contaminants that could impair their operational efficiency.

Functions of Lathe Bellow Covers

The primary function of lathe bellow covers is to safeguard the machine’s moving parts. The lathe is composed of various intricate components that work together with precision. During machining operations, metal shavings, coolant sprays, and other debris can accumulate and damage these components. Bellow covers serve as a barrier, preventing these unwanted materials from entering critical areas and reducing the risk of wear and tear.

Another important function of bellow covers is to provide a degree of safety for operators. By covering moving parts, these bellows help to minimize the risk of accidental contact with machinery. This is particularly important in industrial settings where high-speed operations are common.

Additionally, lathe bellow covers can also be a part of the machine's aesthetic. Well-maintained lathes with intact bellow covers present a more professional appearance, which can be advantageous in client-facing scenarios.

Benefits of Lathe Bellow Covers

There are numerous benefits associated with using lathe bellow covers. First and foremost, they contribute to enhanced machine longevity. By protecting the internal components from abrasive particles and contaminants, bellows help reduce maintenance needs and extend the operational life of the lathe.

Moreover, using bellow covers can improve machining accuracy. When debris or coolant enter sensitive areas, they can cause misalignments and inaccuracies in the machining process. Bellows prevent such occurrences, ensuring that the machine retains its precision.

lathe bellow cover

Cost-effectiveness is another significant advantage. While there is an initial investment in acquiring and installing these covers, the long-term savings achieved through reduced maintenance costs and increased machinery life span are substantial.

Selecting the Right Lathe Bellow Cover

Choosing the appropriate lathe bellow cover is crucial for maximizing the benefits mentioned above. Several factors should be considered during selection

1. Material Depending on the environment in which the lathe operates, different materials might be more suitable. For high-temperature applications, silicone or rubber might be appropriate, while environments with chemicals might require PVC or other resistant materials.

2. Size and Fit It's essential that the bellow covers are properly sized and fitted to the specific lathe model. Ill-fitting covers can lead to gaps, diminishing their protective capabilities.

3. Durability The expected lifespan and wear resistance of the bellows should be evaluated, particularly for heavy-duty applications where high levels of friction and wear are commonplace.

4. Flexibility Depending on the machine's operational movement, the chosen covers should provide ample flexibility to accommodate the full range of motion without restricting function.

5. Ease of Installation and Replacement Covers should be easy to install and replace. Manufacturers that prioritize user-friendly designs can significantly reduce downtime during maintenance.

Conclusion

Lathe bellow covers play an essential role in ensuring the smooth operation of lathes by protecting critical internal components from contaminants and debris. Their significance extends beyond mere protection, contributing to safety, aesthetics, and cost-effectiveness. When selecting the right bellow covers, consideration of material, size, durability, flexibility, and installation ease is vital. By investing in high-quality lathe bellow covers, manufacturers can enhance the performance and longevity of their machinery, leading to improved productivity and reduced operational costs.