Innovative Solutions for Protecting Lathe Equipment with Durable Bellow Covers and Their Benefits

The Importance of Lathe Bellow Covers in Machinery

In various industrial applications, the lathe plays a crucial role in shaping and manufacturing components. However, with the precision that lathes offer, there is also a significant responsibility to maintain the equipment. One essential component that often flies under the radar is the lathe bellow cover. These protective covers serve as a barrier against contaminants, debris, and damage, ensuring the longevity and efficiency of the lathe machine.

Functionality and Purpose

Lathe bellow covers are flexible protective sleeves that encase the moving parts of a lathe, typically the guide ways and spindle. Their primary function is to prevent the ingress of dust, chips, coolant, and other debris that could interfere with the precision movement of the machine's components. By shielding these sensitive areas, bellow covers help maintain the accuracy and operational capability of the lathe over time.

Moreover, lathe bellow covers are designed to absorb shocks and minimize vibrations, which can be detrimental to the machinery’s performance. In high-speed machining scenarios, even minor fluctuations can lead to discrepancies in the finished product. By dampening these vibrations, bellow covers help in achieving superior machining accuracy.

Materials and Design

Lathe bellow covers are typically made from materials such as rubber, polyurethane, or PVC, which provide durability and resistance against wear and tear. The choice of material can greatly influence the lifespan and efficiency of the bellow cover. For example, rubber covers offer excellent flexibility and resilience, making them suitable for high-temperature environments, whereas PVC may be preferred for lighter-duty applications.

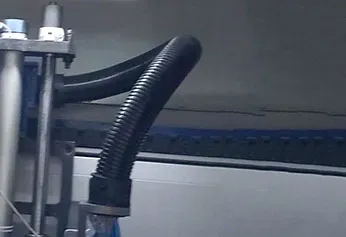

lathe bellow cover

The design of the bellow covers is also crucial. They are crafted in accordion-like folds, allowing them to stretch and compress with the movement of the machine’s components. This design ensures that the covers can accommodate various lathe configurations and movements while providing maximum protection.

Maintenance and Care

Like any other machine component, lathe bellow covers require regular maintenance to ensure their effectiveness. Users should regularly inspect them for signs of wear, such as cracks, tears, or other forms of damage. Since bellow covers are often exposed to harsh operational conditions, it is essential to replace them promptly if any damage is identified. Failing to maintain these covers can lead to increased wear on the lathe's guide ways and other critical components, potentially resulting in costly repairs and downtime.

Additionally, cleaning the bellow covers is vital. Over time, particles can accumulate on their surface, which may cause abrasion and damage. A simple cleaning routine can extend the lifespan of bellow covers and, by extension, the machinery itself.

Conclusion

In conclusion, lathe bellow covers are an often-overlooked yet crucial component in the realm of precision machining. Their role in protecting sensitive areas from debris and damage cannot be understated. By investing in quality bellow covers and adhering to regular maintenance practices, manufacturers can not only enhance the operational longevity of their lathes but also improve the overall quality of their products. Given the critical nature of precision in manufacturing, the importance of maintaining the integrity of the lathe through proper bellow cover use is clear. As technology continues to advance, the relevance and need for effective protective solutions like lathe bellow covers will only grow, underscoring their importance within the industry.