Innovative Solutions for Enhancing Efficiency with Plastic Drag Chains in Industrial Applications

Understanding Plastic Drag Chains An Essential Component in Modern Automation

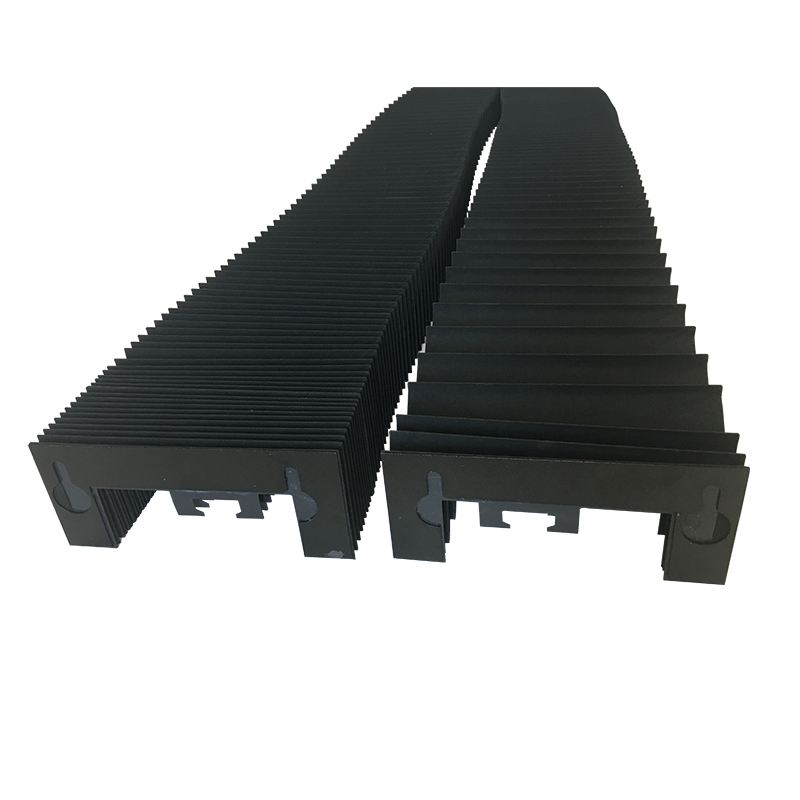

In the realm of modern industry and automation, the integration of various mechanical components plays a crucial role in optimizing efficiency and performance. One such component that has garnered significant attention is the plastic drag chain. These innovative structures are essential for protecting and guiding cables and hoses in dynamic environments, particularly in applications involving robotics, CNC machines, and other automated systems.

What is a Plastic Drag Chain?

Plastic drag chains, also known as energy chains, are flexible channels designed to hold and organize multiple cables and hoses while allowing for smooth movement. They are typically made from durable plastic materials such as nylon or polypropylene, which provide a combination of strength and flexibility. These chains consist of interconnected links, allowing them to bend and flex as machinery operates, thereby facilitating the smooth transmission of power and data.

Benefits of Plastic Drag Chains

1. Durability One of the primary advantages of plastic drag chains is their resistance to wear and tear. The high-quality plastic used in their construction can withstand harsh conditions, including exposure to chemicals, dirt, and extreme temperatures. This durability ensures a long lifespan, reducing the need for frequent replacements and maintenance.

2. Flexibility Unlike traditional metal chains, plastic drag chains offer a high degree of flexibility. This attribute is particularly beneficial in applications where space is limited or where machinery needs to move in various directions. Their lightweight nature contributes to reduced load on the motors and actuators they support.

3. Noise Reduction Plastic drag chains provide excellent noise-dampening properties compared to their metal counterparts. This reduction in noise is crucial in environments where sound levels must be minimized, such as in laboratories or offices where CNC machines operate.

plastic drag chain

4. Easy Installation and Maintenance The design of plastic drag chains allows for straightforward installation. They come with various mounting options and can be easily adjusted to fit specific requirements. Additionally, maintenance is simplified, as cables can be replaced or re-routed without disassembling the entire system.

5. Versatility Plastic drag chains are used in a wide range of applications across multiple industries, including manufacturing, automotive, aerospace, and robotics. Their ability to organize and protect cables and hoses makes them an integral part of automated systems, ensuring reliable operation.

Applications of Plastic Drag Chains

Plastic drag chains find extensive use in several industries

- Manufacturing In assembly lines, where repetitive movements are common, drag chains help manage cables that power machinery. - Robotics Robots often require precise movement and power supply management. Drag chains provide a clean solution for guiding cables, ensuring that they do not snag or get damaged during operation. - CNC Machines These machines require complex setups involving numerous cables for control and power. Plastic drag chains help keep these cables organized and functioning optimally.

Conclusion

In summary, plastic drag chains are a vital element in the modern landscape of automation and manufacturing. Their combination of durability, flexibility, and ease of maintenance makes them an ideal choice for managing cables and hoses in dynamic environments. As industries continue to evolve, the demand for efficient and reliable components like plastic drag chains will undoubtedly grow, cementing their place as indispensable tools in the world of automation. The innovative design and application of these chains not only enhance operational efficiency but also contribute to the overall safety and reliability of complex machinery.