Innovative Solutions for Enhanced Performance in Cable Carrier Systems and Their Applications

Cable Carrier Systems An Essential Component for Efficient Motion Control

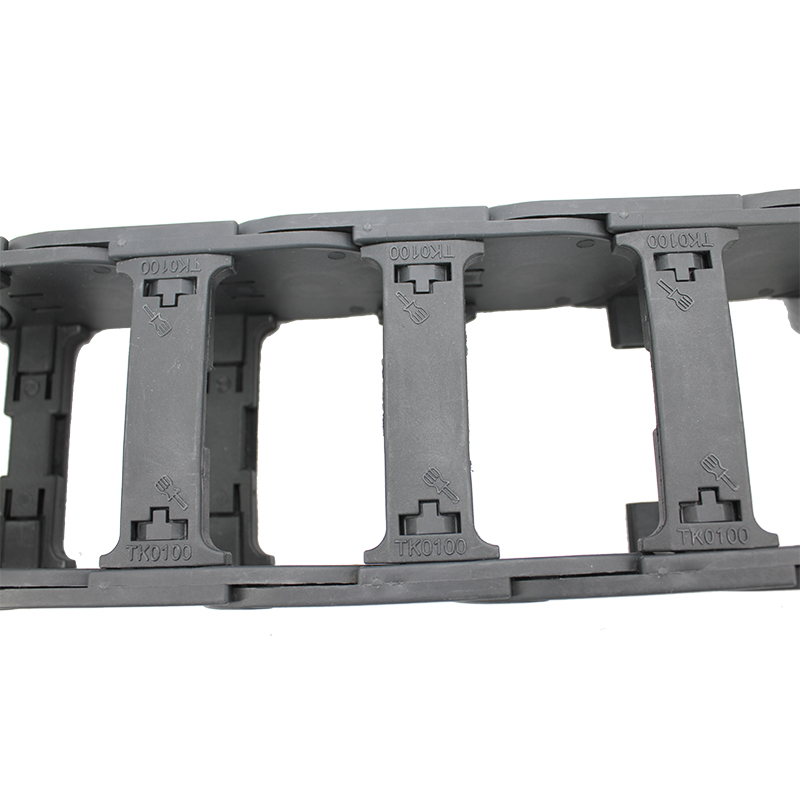

In the realm of industrial automation and machinery, the optimization of movement and cable management is crucial for ensuring operational efficiency and safety. One of the most effective solutions for addressing these challenges is the use of cable carrier systems. These systems, also known as drag chains or cable chains, serve to protect and guide cables and hoses in dynamic applications, enabling smoother operations and reducing wear and tear.

What are Cable Carrier Systems?

Cable carrier systems consist of a series of interconnected links that create a flexible channel for cables and hoses to travel along. These carriers are designed to manage the elongation and contraction of cables as machinery moves. In many applications, such as robotics, CNC machines, and automated production systems, connectors and hose assemblies are subjected to continuous bending and flexing, which can lead to cable failure, friction, and entanglement. Cable carriers provide a structured pathway, effectively mitigating these issues.

Key Benefits of Cable Carrier Systems

1. Protection The primary function of cable carrier systems is to protect cables and hoses from abrasion and crushing. Industrial environments can be harsh, and without proper protection, cables can wear out quickly or become damaged, leading to costly downtime.

2. Organization Cable carrier systems help organize cables and hoses, preventing tangling and ensuring that they are easily accessible during maintenance or repairs. This organization not only improves the aesthetics of a workspace but also enhances safety and reduces the risk of accidents due to tripping hazards.

cable carrier systems

3. Flexibility The modular design of cable carriers allows for customization to fit specific applications. They come in various sizes, shapes, and materials, catering to different environmental conditions, such as high temperatures, chemicals, or outdoor settings.

4. Movement Efficiency Cable carrier systems facilitate smooth and consistent movement during operation. By ensuring the proper layout of cables, they reduce resistance and friction, leading to improved mechanical efficiency and less stress on both cables and machinery.

5. Reduced Maintenance With proper cable management, wear and tear on cables and hoses are minimized, which translates to lower maintenance costs. Users benefit from extended service life for their equipment, as well as decreased frequency of replacements.

Applications of Cable Carrier Systems

Cable carrier systems are versatile and can be found in a range of applications across various industries. In the manufacturing sector, they are commonly utilized in CNC machining centers, robotic arms, and material handling equipment. In construction and equivalent applications, they are used in cranes, hoists, and conveyors. Moreover, industries such as aerospace and automotive leverage these systems to maintain the integrity of wiring and hydraulic systems in moving applications.

Conclusion

In summary, cable carrier systems play a vital role in modern industrial operations by enhancing cable management and protecting essential components. Their benefits, including increased efficiency, reduced maintenance, and improved safety, make them indispensable throughout various sectors. As automation continues to evolve and machinery becomes more complex, the need for reliable and effective cable management solutions like cable carrier systems will only grow, ensuring seamless and efficient operations in the future. The integration of these systems can ultimately drive productivity and enhance the longevity of equipment, making them a sound investment for any enterprise engaged in dynamic and high-demand environments.