Innovative Solutions for Efficient Cable Management with CNC Cable Chain Systems for Industrial Applications

Understanding CNC Cable Chains Essential Components for Automation

In the realm of modern manufacturing and automation, CNC (Computer Numerical Control) machinery plays a pivotal role in ensuring precision and efficiency in the production process. One crucial component that facilitates the smooth operation of CNC machines is the cable chain, also known as a drag chain or energy chain. This article delves into the significance of CNC cable chains, their functions, and their benefits in automated systems.

What Is a CNC Cable Chain?

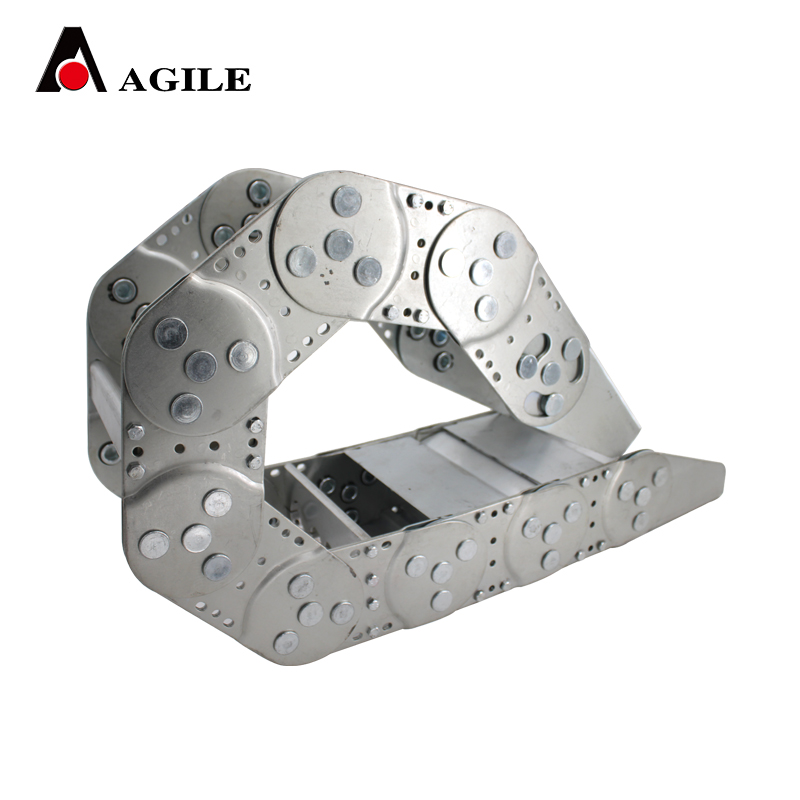

A CNC cable chain is a flexible conveyor system designed to organize and protect cables and hoses in machinery. These chains are engineered to manage power supply cables, control cables, pneumatic tubes, and other flexible conduits. Typically made from materials like plastic or metal, cable chains come in various shapes and sizes to accommodate different applications and environments.

Functions of CNC Cable Chains

1. Cable Protection One of the primary roles of cable chains is to shield cables from damage. In CNC setups, cables are often exposed to dynamic movements and harsh environments. Cable chains help prevent wear and tear, reducing the risk of electrical failure due to frayed cables or insulation damage.

2. Organization With multiple cables and hoses running through a CNC machine, keeping them organized is essential. Cable chains provide a structured path for cables, minimizing tangles and ensuring a clean, orderly workspace.

3. Flexibility and Mobility CNC machines often require movement along multiple axes. Cable chains are designed to be flexible, allowing cables to move freely as the machine operates. This flexibility is crucial for maintaining performance and extending the lifespan of both cables and machinery.

cnc cable chain

4. Safety An organized cable system reduces trip hazards in the production area. By containing and routing cables along predictable paths, cable chains not only enhance operational safety but also contribute to regulatory compliance associated with workplace safety standards.

Benefits of Using CNC Cable Chains

1. Enhanced Durability CNC cable chains are engineered to withstand the rigors of industrial environments. Their robust construction ensures that they can handle repetitive motion and exposure to dust, debris, and temperature fluctuations without compromising performance.

2. Reduced Downtime Regular maintenance and replacements of damaged cables can lead to significant downtime in production. By implementing cable chains, businesses can minimize the frequency of cable damage, thus reducing maintenance costs and downtime associated with machine repairs.

3. Improved Efficiency Well-organized cables streamline the operation of CNC machines. This organization not only speeds up installation but also simplifies troubleshooting and repairs. As a result, operators can focus more on production rather than managing tangles and malfunctions.

4. Customization CNC cable chains can be tailored to fit specific machinery requirements. Manufacturers offer a wide range of profiles, lengths, and accessories, allowing companies to create a customized solution that best fits their operational needs.

Conclusion

CNC cable chains are integral to maintaining a functional and efficient manufacturing environment. By providing protection, organization, flexibility, and safety for cables and hoses, these systems contribute significantly to the overall performance of CNC machinery. As automation continues to evolve, the importance of reliable components like cable chains will only become more pronounced, ensuring that businesses remain competitive in an increasingly automated world. Investing in quality cable chains can lead to enhanced productivity, reduced operational costs, and a safer working environment, making them an essential component for any modern manufacturing setup.