Innovative Solutions for Efficient Cable Management in Industrial Machine Applications

Understanding Machine Cable Tracks A Comprehensive Overview

In the world of industrial automation and machinery, the term cable track refers to a critical component that ensures the efficient and safe management of cables and hoses in moving applications. Whether in factories, warehouses, or construction sites, machine cable tracks play an essential role in maintaining the integrity of electrical connections and fluid transfer systems. This article delves into the significance, types, benefits, and applications of machine cable tracks.

What Are Machine Cable Tracks?

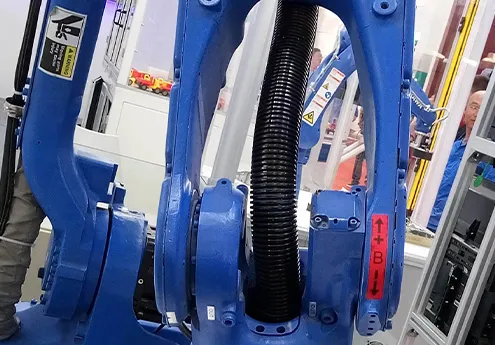

Machine cable tracks, also known as cable carriers or drag chains, are designed to guide and protect cables and hoses as they move with machinery. These tracks are often made from a durable plastic or metal material, ensuring they can withstand the stresses of constant motion while minimizing wear and tear on the cables themselves. By providing a clear path for cables, they prevent tangling, kinking, and damage that could lead to costly downtime and repairs.

Types of Cable Tracks

Cable tracks come in various types and configurations, tailored to suit specific industrial needs

1. Plastic Cable Tracks Lightweight and flexible, plastic tracks are ideal for applications that require versatility. They are corrosion-resistant and can be easily modified to accommodate different cable sizes and types.

2. Steel Cable Tracks These tracks are known for their robustness and durability. Steel cable tracks are often used in heavy-duty applications where significant loads and stresses are involved.

3. Modular Cable Tracks Designed for adaptability, modular tracks allow for customization to fit specific machinery layouts. This flexibility makes them suitable for unique machinery designs and configurations.

4. Energy Chains A more advanced version, energy chains not only guide cables but also allow for a continuous supply of power and data signals, making them suitable for dynamic environments.

Benefits of Using Cable Tracks

Implementing machine cable tracks provides several advantages

machine cable track

- Protection Protecting cables from physical damage, dust, and environmental factors prolongs their lifespan and maintains efficient operation

.- Organization By keeping cables neatly arranged, cable tracks help reduce clutter in work areas and promote safety by preventing tripping hazards.

- Efficiency Streamlined movement reduces friction and enhances the efficiency of machinery, allowing for smoother operations without cable interference.

- Maintenance Ease With cables properly routed within tracks, maintenance becomes simpler, which can lead to reduced downtime during equipment servicing.

Applications of Machine Cable Tracks

The versatility of cable tracks means they find applications across a wide array of industries

- Manufacturing In automated assembly lines, cable tracks manage the movement of power and control cables seamlessly alongside robotic arms and conveyor systems.

- Construction Heavy machinery on construction sites can benefit from cable tracks to safeguard electrical and hydraulic lines from intense movement and environmental hazards.

- Aerospace and Automotive In these precision-driven sectors, maintaining cable integrity is crucial, making cable tracks an essential component in assembly and testing facilities.

- Entertainment In theaters and studios, movable lights and cameras utilize cable tracks to ensure that cables do not obstruct performance while maintaining flexibility and rapid repositioning.

Conclusion

Machine cable tracks are indispensable in the modern industrial landscape. They play a vital role in enhancing productivity, reliability, and safety in various applications. By understanding the types and benefits of cable tracks, manufacturers and operators can make informed decisions that lead to improved machine performance and operational efficiency. As technology continues to evolve, so too will the designs and functionalities of cable tracks, ensuring they remain integral to the safe and effective operation of industrial machinery.