Innovative Magnetic Conveyor System for Efficient Chip Transport and Sorting Solutions

The Innovative Magnetic Chip Conveyor Revolutionizing Material Handling

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One technology that has emerged to enhance these aspects is the magnetic chip conveyor. This innovative solution is specifically designed for the transportation of metal chips, shavings, and other debris that are produced during machining processes. By employing magnetic forces, these conveyors not only ensure safe and reliable handling of materials but also contribute significantly to operational efficiency.

Understanding the Technology

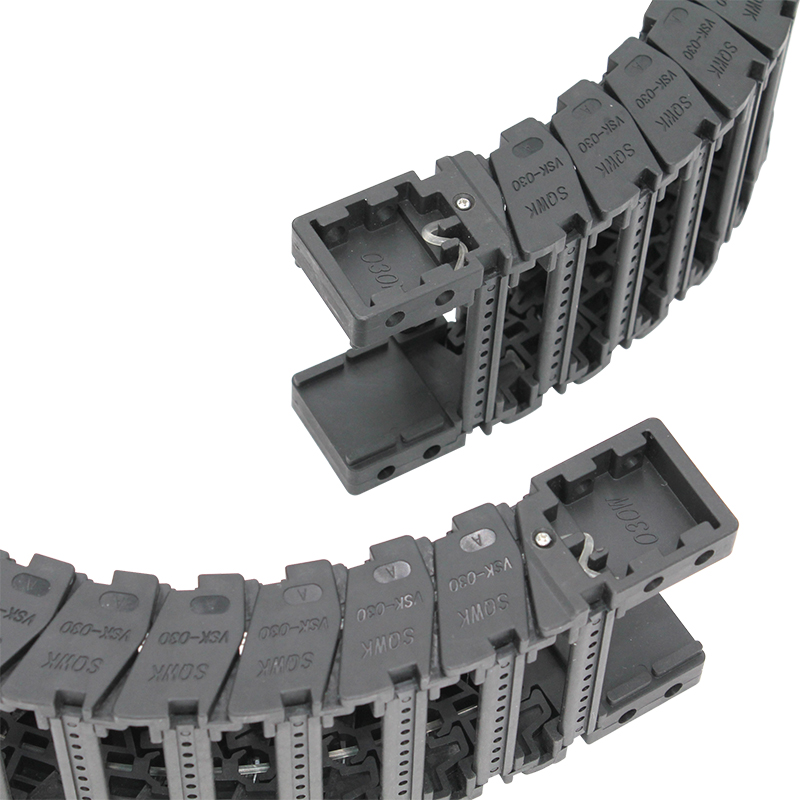

Magnetic chip conveyors operate on the principle of magnetism to move ferrous materials seamlessly. They consist of a belt or a series of magnetic plates that attract and hold metal chips securely as they travel along the conveyor system. This is particularly advantageous in environments where traditional conveyor systems might struggle to manage stray materials, ensuring that virtually all generated debris is collected and transported for recycling or disposal.

The magnetic component of these conveyors typically includes permanent magnets or electromagnetic systems that can be adjusted to accommodate various sizes and types of metal fragments. The conveyor design often features a moving belt or chain that allows for continuous transport of the collected materials to a designated disposal unit or recycling station. These features not only help maintain a clean and safe working environment but also reduce the manual labor required for cleanup and material handling.

Advantages of Magnetic Chip Conveyors

1. Enhanced Efficiency The primary benefit of magnetic chip conveyors is their ability to streamline the material handling process. By automatically collecting and transporting metal chips, manufacturers can reduce downtime associated with manual cleanup and increase machine uptime.

magnetic chip conveyor

2. Reduced Labour Costs The elimination of manual handling of metal scraps lowers labor costs significantly. Workers can focus on critical manufacturing tasks instead of spending time cleaning up debris, leading to a more productive workforce.

3. Improved Safety A cleaner workspace translates to a safer environment for employees. With metal chips and shavings securely transported away from machinery, the risk of accidents caused by slipping or tripping on debris is minimized.

4. Environmental Benefits Magnetic chip conveyors aid in promoting sustainable manufacturing practices by efficiently collecting metal scraps for recycling. This not only reduces waste but also encourages the reuse of materials, contributing to a more eco-friendly production cycle.

5. Versatility These conveyors can be integrated into various types of machinery and configured to suit different production environments. Their adaptability makes them suitable for a wide range of industries, from automotive to aerospace, where precision machining is crucial.

Conclusion

As industries strive for enhanced efficiency and sustainability, magnetic chip conveyors are proving to be an essential component of modern manufacturing processes. Their innovative design and numerous advantages highlight the transformative power of technology in improving operational effectiveness. By enabling manufacturers to handle metal scraps efficiently, these conveyors not only streamline operations but also promote a safer and more sustainable approach to production. With ongoing advancements in technology, the future of magnetic chip conveyors looks promising, poised to drive further improvements in material handling and manufacturing processes across various sectors.