Infinite Synchronous Belts for Enhanced Performance and Reliability in Mechanical Systems

Endless Synchronous Belts Revolutionizing Mechanical Power Transmission

In the realm of mechanical engineering, the quest for efficient power transmission systems is never-ending. Among the various solutions available, endless synchronous belts have emerged as a leading choice, revolutionizing the way power is transmitted in a multitude of applications. This innovation not only enhances performance but also extends the lifespan of machinery, making it a dominant player in many industrial settings.

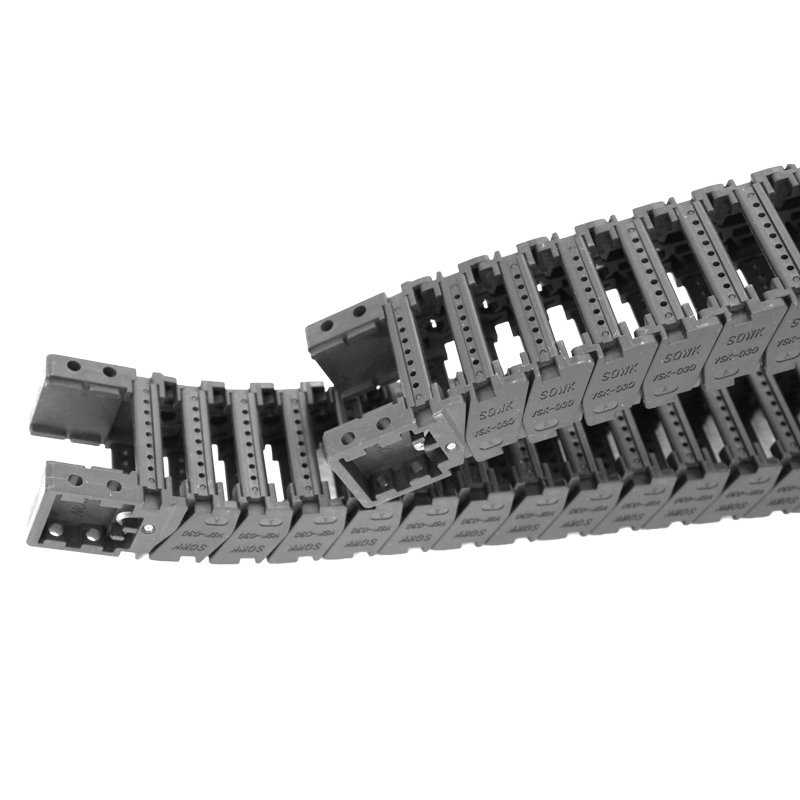

Endless synchronous belts are part of a category known as synchronous belts, designed to transmit power through the engagement of teeth on the belt with the corresponding grooves on the pulleys. The “endless” nature of these belts refers to their looped design, which eliminates any splicing or joints that could potentially weaken the belt and lead to failure during operation. This continuous design contributes to a higher efficiency of power transmission, often exceeding 95%, and results in lower energy losses when compared to other belt systems.

One of the foremost advantages of endless synchronous belts is their precision in maintaining the timing of moving parts. In applications where the synchronization of components is critical—such as in automotive engines, conveyor systems, and robotics—these belts ensure that there is minimal slack or slippage. This precision allows for consistent performance, reducing wear and tear on the machinery and enhancing overall operational reliability.

In addition to their precision, these belts exhibit a high degree of versatility. They are manufactured in a variety of materials, including rubber, polyurethane, and even composite materials, allowing for specific characteristics tailored to various operating environments. For instance, polyurethane belts offer excellent resistance to abrasion, chemicals, and extreme temperatures, making them suitable for harsh industrial applications. This versatility provides engineers with the flexibility to select the right belt for their specific operational needs, whether that involves high-speed applications or environments exposed to contaminants.

endless synchronous belts

The installation and maintenance of endless synchronous belts also come with significant benefits. Unlike traditional V-belts, which can require frequent tension adjustments and replacements due to wear and tear, synchronous belts maintain tension over a more extended period. This low-maintenance requirement translates to reduced downtime and operational costs for businesses, contributing to improved productivity. Furthermore, the absence of tensioners or idlers in some designs simplifies the installation process, enabling quicker setup without compromising reliability.

Sustainability is an increasingly important factor in manufacturing and engineering practices. Endless synchronous belts contribute positively to sustainability efforts by improving energy efficiency and reducing waste. The high efficiency of these belts leads to lower energy consumption, aligning with the global push toward more environmentally friendly practices. Additionally, the long lifespan of synchronous belts results in less frequent replacements, subsequently generating less waste over time.

As technological advancements continue to push the boundaries of engineering, the role of endless synchronous belts is likely to expand. From the automotive industry to packaging and material handling systems, the demand for efficient, reliable, and sustainable power transmission solutions is set to rise. Manufacturers are also exploring new designs and materials that could further enhance the performance of these belts, paving the way for innovations that could reshape the industry.

In conclusion, endless synchronous belts represent a significant advancement in power transmission technology. Their precision, versatility, low maintenance requirements, and sustainability benefits make them an essential component in modern mechanical systems. As industries evolve and strive for higher efficiency and reliability, the reliance on such innovative solutions will undoubtedly continue to grow, ensuring that endless synchronous belts remain at the forefront of engineering excellence.