Hinged Belt Conveyor Systems for Efficient Chip Transport Solutions in Manufacturing

The Advantages and Applications of Hinged Belt Chip Conveyors

In the realm of industrial manufacturing, efficient material handling systems are critical for optimizing productivity and minimizing downtime. One such innovative solution is the hinged belt chip conveyor. This type of conveyor system is specifically designed for transporting metal chips and other scrap materials generated during machining processes. Its unique construction, operational efficiency, and versatility have made it an indispensable tool in many manufacturing environments.

Understanding Hinged Belt Chip Conveyors

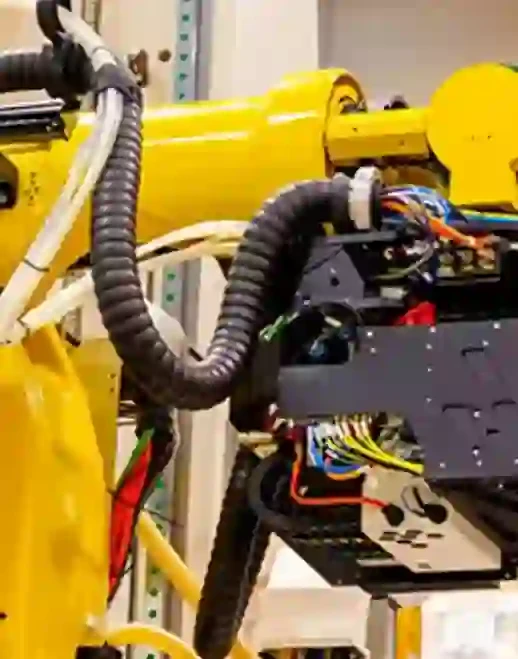

A hinged belt chip conveyor consists of a series of interlinked metal belts with some form of hinge mechanism. Unlike traditional conveyors, which often rely on a flat belt, hinged belt systems allow for a more rugged and flexible approach to handling heavy and bulky materials. The design accommodates chips of various shapes and sizes, including metal curls, chunk scrap, and fine swarf, which makes them ideal for diverse machining applications such as milling, turning, and grinding.

Key Features and Benefits

1. Durability Hinged belt chip conveyors are constructed from robust materials that can withstand the harsh conditions present in machine shops. The ability to handle heavy loads and resist wear and tear ensures that these conveyors have a long operational life, reducing the need for frequent maintenance or replacement.

2. Efficient Material Handling These conveyors effectively remove metal chips from machining equipment, minimizing the risk of equipment jams and increasing overall productivity. By continuously transporting waste away from machinery, manufacturers can maintain smoother operations and focus on production without interruptions.

3. Versatility Hinged belt chip conveyors can be tailored to fit various layouts and configurations within a manufacturing facility. They can operate on inclines, declines, and horizontal runs, making them adaptable to different setups. This versatility allows for optimized workflows, as scrap can be directed to centralized collection points or waste disposal systems.

4. Easy Integration The modular nature of hinged belt chip conveyors enables easy integration into existing systems. They can be implemented in new machine setups or retrofitted to enhance older machines. This adaptability facilitates upgrades in manufacturing processes without extensive overhauls.

hinged belt chip conveyor

5. Enhanced Safety By effectively removing metal chips and debris from the work area, hinged belt chip conveyors contribute to a safer work environment. Reducing the accumulation of waste materials decreases the chances of slips, trips, and falls while ensuring that workers can operate machines without hindrance.

Applications in Industry

Hinged belt chip conveyors find applications across various industries, particularly in metalworking and manufacturing. Their ability to handle diverse types of waste material makes them suitable for

- Machining Plants In facilities where precision machining occurs, hinged belt chip conveyors are essential for efficiently transporting metal shavings and offcuts away from the machinery.

- Automotive Manufacturing The automotive industry generates considerable metal waste during production processes. Hinged belt chip conveyors help manage this waste, ensuring production lines remain clean and efficient.

- Aerospace Similar to automotive manufacturing, the aerospace sector involves high precision and generates specific types of scrap. Hinged belt conveyors are deployed to handle these specific waste requirements effectively.

- Fabrication Shops Companies that specialize in metal fabrication use hinged belt chip conveyors to manage the chips and scrap generated during cutting, bending, and assembly processes.

Conclusion

Hinged belt chip conveyors represent a critical component of efficient material management in manufacturing environments. Their robust construction, versatility, and ability to enhance operational efficiency make them a preferred choice for companies looking to optimize their waste handling processes. As industries continue to evolve and innovate, the reliance on such specialized equipment will only increase, further solidifying the importance of hinged belt chip conveyors in modern manufacturing practices. By investing in these systems, manufacturers can ensure that they remain competitive while promoting a cleaner and safer working environment.