hinged belt chip conveyor

Hinged Belt Chip Conveyor An Essential Tool for Efficient Manufacturing

In modern manufacturing environments, the need for efficient material handling solutions has become essential. Among the various equipment used in this sector, the hinged belt chip conveyor stands out as a vital component for transporting chips, scrap, and other byproducts generated during machining processes. This article delves into the design, functionality, and advantages of hinged belt chip conveyors, illustrating their significance in enhancing operational efficiency.

Understanding Hinged Belt Chip Conveyors

Hinged belt chip conveyors, as their name suggests, utilize a series of hinged metal belts to transport materials. These conveyors are specifically designed to handle chips produced by various machining operations such as milling, grinding, and turning. The robust design of the hinged belts allows for seamless transportation of both small and large chips, as well as various types of materials including metal, plastic, and wood.

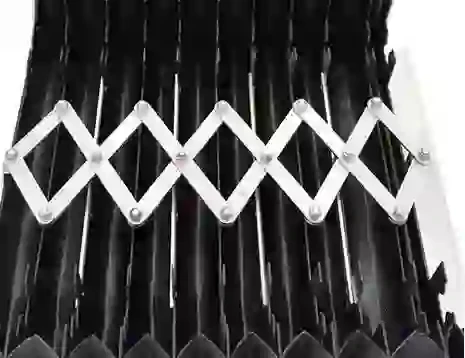

The conveyor consists of multiple links that are connected with pins, creating a continuous belt that moves around pulleys. This design not only provides versatility in handling different material shapes and sizes but also minimizes the risk of blockages and jams, which can be significant issues in manufacturing environments. The open structure of the hinged belts facilitates easy cleaning and maintenance, which is crucial in any production setting.

Benefits of Hinged Belt Chip Conveyors

1. Durability and Strength One of the primary advantages of hinged belt chip conveyors is their durable construction. Made from high-quality materials, these conveyors can withstand heavy loads and harsh operating conditions, ensuring a long service life. This durability reduces the need for frequent replacements, leading to cost savings for manufacturers.

hinged belt chip conveyor

2. Efficient Material Handling The design of hinged belt chip conveyors allows for efficient loading and unloading of materials. They can handle large volumes of chips and scrap metal without significant delays, which is vital in maintaining the overall workflow in a manufacturing environment. By ensuring that waste materials are swiftly removed from the production area, these conveyors help optimize machine performance and minimize downtime.

3. Versatility Hinged belt chip conveyors are versatile and can be customized to meet specific manufacturing needs. They can be configured in various lengths and widths, and can even be designed to operate at different angles. This adaptability makes them suitable for a wide range of applications across numerous industries, from automotive to aerospace.

4. Operational Safety The design of hinged belt conveyors not only enhances efficiency but also promotes safety in the workplace. By effectively managing waste materials, they help reduce clutter and hazards associated with material spills. Additionally, their enclosed structure can help prevent accidents related to moving parts, contributing to a safer working environment.

5. Integration Capabilities These conveyors can easily integrate with existing manufacturing systems, including automated machinery and sorting equipment. This capability enables manufacturers to create a seamless workflow, further enhancing operational productivity.

Conclusion

In conclusion, hinged belt chip conveyors are an essential component of modern manufacturing operations. Their robust design, efficiency in material handling, and versatility make them a go-to solution for managing chips and scrap production. By investing in quality hinged belt chip conveyors, manufacturers can not only streamline their operations but also foster a safer, more productive work environment. As industries continue to evolve, the demand for effective material handling tools like these will only grow, making them indispensable in the quest for enhanced manufacturing efficiency.