Hinged Belt Conveyor Systems for Efficient Chip Handling in Manufacturing Industries

The Innovative Hinged Belt Chip Conveyor Revolutionizing Material Handling

In today’s manufacturing world, efficient material handling is paramount. Among the various systems designed to facilitate this process, the hinged belt chip conveyor stands out as an innovative solution tailored for specific needs, particularly in industries involving metalworking, plastics, and other manufacturing processes that generate chips and scrap materials.

Understanding Hinged Belt Chip Conveyors

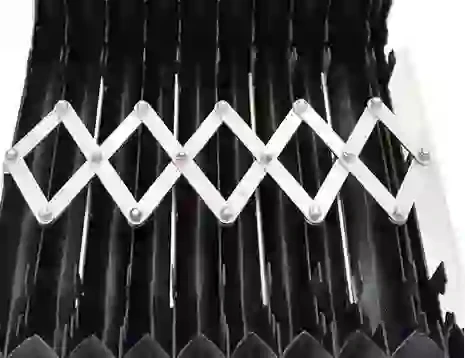

Hinged belt chip conveyors are specialized types of conveyors designed to transport metal chips, shavings, and other scrap materials away from production machinery. The key feature of these conveyors is their hinged belt structure, which consists of interconnected metal plates or links that create a durable and flexible belt. This unique design not only supports the movement of heavy chips but also enables the system to work in various configurations—be it inclined, horizontal, or even declining.

Design and Functionality

The design of the hinged belt chip conveyor is robust, making it suitable for the harsh environments typical in manufacturing. The steel or heavy-duty plastic links can withstand the abrasive nature of metal shavings, while the belt’s flexibility allows it to navigate around corners and transitions with ease. This adaptability is critical in manufacturing settings, where space is often limited, and the arrangement of machinery can vary greatly.

The functionality of these conveyors is straightforward yet efficient. As chips and scrap materials are produced, they are collected and funneled into the conveyor system. The hinged belt then moves these materials through the conveyor track, where they can be collected for recycling, disposal, or further processing. This not only keeps the work area cleaner but also minimizes downtime by ensuring that machines operate smoothly without the risk of clogging.

Benefits of Hinged Belt Chip Conveyors

hinged belt chip conveyor

One of the primary advantages of hinged belt chip conveyors is their durability. The materials used in their construction can endure heavy loads and abrasive substances, promising a long service life with minimal maintenance. This reliability translates to reduced operational costs over time.

Another significant benefit is the conveyor's ability to handle various types of materials, including small, large, and irregularly shaped chips. This versatility makes it an ideal choice for factories dealing with multiple types of machining processes. Moreover, hinged belt conveyors can be customized with different configurations and attachments to accommodate specific operational needs, ensuring that businesses find an optimal solution tailored to their requirements.

Additionally, these systems enhance workplace safety and efficiency. By removing debris and chip materials from the work area, they reduce the risk of accidents and injuries. Clean and organized workspaces not only improve safety but also boost productivity, as workers can focus on their tasks without the distraction of clutter.

Environmental Impact

In an age where sustainability is increasingly important, hinged belt chip conveyors contribute positively by facilitating the recycling of metal chips and shavings. By efficiently transporting these materials to dedicated processing areas, manufacturers can reclaim valuable resources and minimize waste. This not only supports environmentally friendly practices but also enhances profitability by turning waste materials into reclaimed resources.

Conclusion

As industries continue to advance and evolve, the need for efficient and reliable material handling solutions remains critical. Hinged belt chip conveyors exemplify innovation in this realm by providing a durable, flexible, and efficient means of managing metal chips and scrap materials. With their ability to enhance productivity, improve safety, and support sustainable practices, these conveyors are transforming the landscape of material handling in manufacturing environments.

Investing in a hinged belt chip conveyor is not just about improving efficiency—it's about adopting a forward-thinking approach towards manufacturing challenges. By integrating such technology into production lines, companies position themselves for future success, ready to meet both operational demands and environmental responsibilities. As we move forward, the role of hinged belt chip conveyors in streamlining manufacturing processes will undoubtedly continue to grow, heralding a new era of industrial efficiency.