hinge chip conveyor

Understanding Hinge Chip Conveyors A Key Component in Material Handling

In various industrial contexts, efficient material handling is crucial for the seamless operation of production lines. One of the innovations that have gained traction in this space is the hinge chip conveyor. This specialized equipment is designed to facilitate the smooth transport of materials, particularly in machining facilities where metal chips, shavings, and other by-products need to be managed effectively.

What is a Hinge Chip Conveyor?

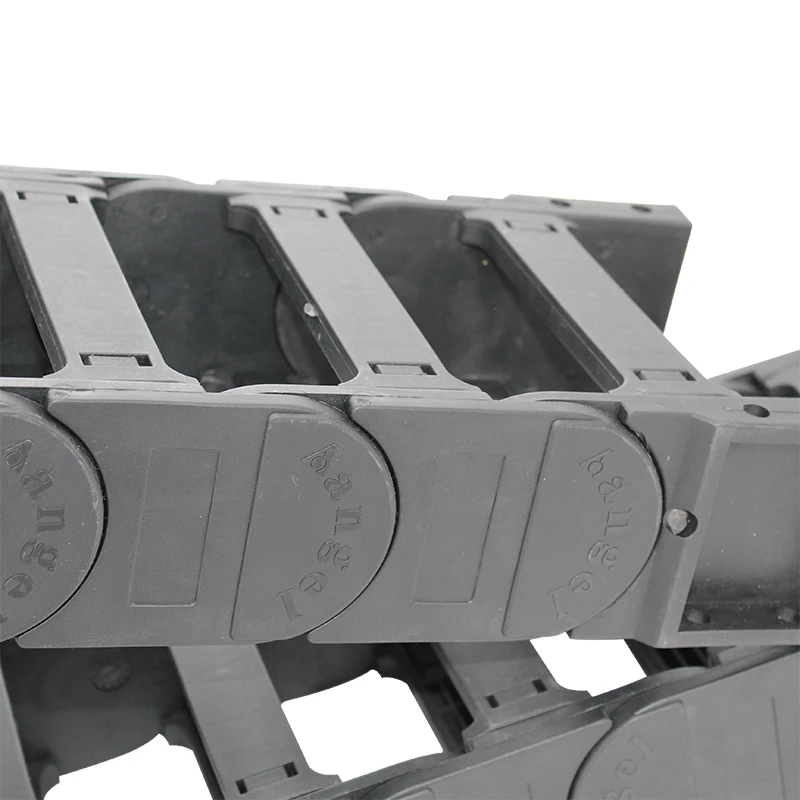

A hinge chip conveyor is designed specifically for moving chips and scrap materials generated from machining processes like milling, turning, and grinding. Its construction typically includes a series of interconnected hinged steel plates or belts that offer durability and flexibility. The hinge features allow the conveyor to traverse various angles and adapt to the layout of the workspace, making it a versatile option for manufacturers facing spatial constraints.

Key Features and Benefits

1. Efficient Chip Handling Unlike traditional conveyor systems, hinge chip conveyors are adept at handling the unique characteristics of metal chips, which can vary in size, shape, and material. The hinged design prevents clogging and ensures a continuous flow of materials, which is crucial for maintaining productivity in a machining environment.

2. Robust Construction The materials used in hinge chip conveyors are generally designed to withstand the harsh conditions of a factory floor. Heavy-duty steel constructions and abrasion-resistant coatings ensure longevity, reducing the frequency of replacements and repairs.

hinge chip conveyor

3. Space-Saving Design Their flexibility allows for vertical and horizontal transport, making it easier to navigate around machinery and equipment without taking up excessive floor space. This is especially important in crowded factory settings where every inch of space counts.

4. Reduced Labor Costs Automating the transport of metal chips significantly decreases manual labor, allowing workers to focus on more value-added tasks. This not only increases productivity but also improves workplace safety by reducing the risk of injury associated with manual handling of heavy loads.

5. Environmental Sustainability By efficiently collecting and transporting machining by-products, hinge chip conveyors contribute to a cleaner work environment. They facilitate the recycling of metal chips and help companies meet sustainability goals by minimizing waste.

Applications in Industry

Hinge chip conveyors find their application across various industries, particularly in automotive, aerospace, and metalworking sectors. They are instrumental in chip removal systems, where the timely evacuation of scrap materials prevents production downtime and equipment malfunction. Implementing these conveyors can lead to remarkable improvements in operational efficiency and workflow.

Conclusion

As the industrial sector continues to evolve, so too does the need for innovative solutions in material handling. Hinge chip conveyors represent a significant technological advancement, streamlining the process of chip removal and enhancing overall productivity in manufacturing environments. Their unique design, robust construction, and multifaceted benefits make them an indispensable part of modern machining operations. For businesses looking to optimize their production processes, investing in a hinge chip conveyor may not only provide economic advantages but also contribute to a more efficient and sustainable operation.