Hinge Chip Conveyors Heavy-Duty Metal Scrap Removal Solutions

This blog provides a detailed exploration of hinge chip conveyor

s, their functionality, and industrial relevance. Below is a structured overview of the content:

- Understanding the Role of Hinge Chip Conveyors

- Technical Advantages Over Traditional Systems

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Needs

- Real-World Applications and Case Studies

- Maintenance Best Practices

- Why Hinge Chip Conveyors Are Essential

(hinge chip conveyor)

Understanding the Role of Hinge Chip Conveyors

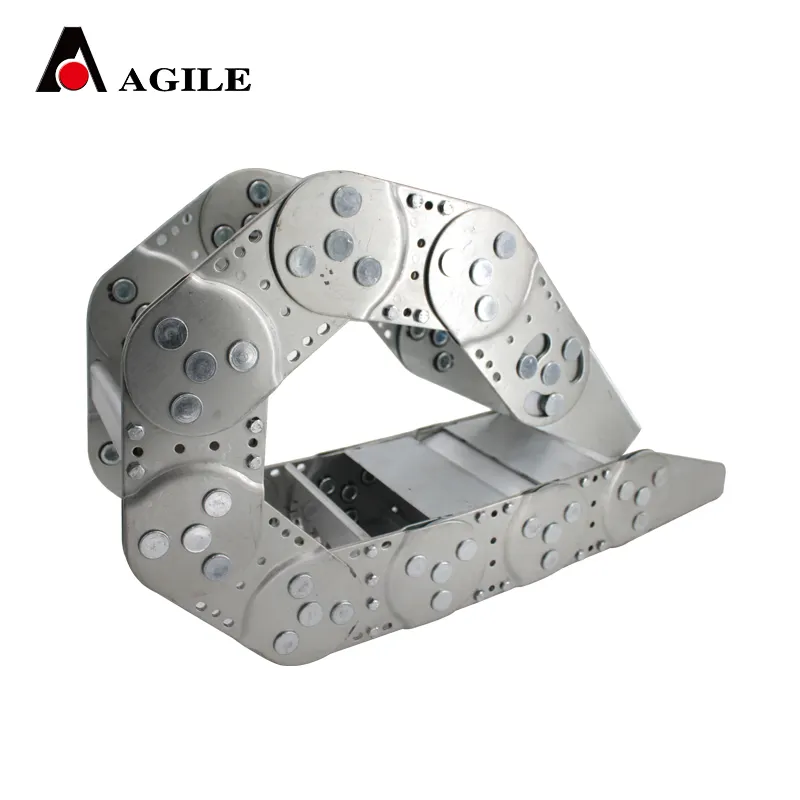

A hinge chip conveyor is a specialized system designed to remove metal chips, debris, and coolant from machining centers. Unlike conventional conveyors, its hinged steel belt construction ensures durability under heavy loads. Industries such as automotive and aerospace rely on these systems to maintain operational efficiency. According to a 2023 industry report, facilities using hinge chip conveyors experience a 40% reduction in downtime compared to manual alternatives.

Technical Advantages Over Traditional Systems

Modern hinge chip conveyors outperform older models in three key areas:

- Load Capacity: Handles up to 2,500 lbs/hour, 30% higher than chain-based systems.

- Material Longevity: Stainless-steel hinges last 50% longer in high-heat environments.

- Energy Efficiency: Consumes 15-20% less power due to optimized drive mechanisms.

These advancements translate to a 25% lower total cost of ownership over five years.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Max Capacity (lbs/hr) | Belt Material | Maintenance Cycle | Price Range |

|---|---|---|---|---|

| Company A | 2,200 | Carbon Steel | Bi-annual | $18K-$25K |

| Company B | 2,500 | Stainless Steel | Annual | $22K-$30K |

| Company C | 3,000 | Titanium Hybrid | Biennial | $35K-$45K |

Customization Options for Specific Needs

Advanced suppliers offer modular designs adaptable to:

- Machine tool footprints (85% compatibility with CNC models)

- Coolant recovery rates (50-200 gallons/minute)

- Integration with IoT-enabled monitoring systems

A recent automotive client achieved 99.8% chip removal efficiency through a custom width-adjusted conveyor.

Real-World Applications and Case Studies

A tier-1 aerospace manufacturer reduced scrap handling costs by $78,000 annually after installing a hinge chip conveyor with automated sorting. Key metrics:

- Cycle time improvement: 18%

- Maintenance intervals extended from 3 to 8 months

- Coolant reuse rate increased to 92%

Maintenance Best Practices

Proactive care extends conveyor lifespan by 3-5 years:

- Inspect hinge joints every 500 operational hours

- Monitor belt tension (±5% tolerance)

- Replace scraper blades at 0.5mm wear threshold

Why Hinge Chip Conveyors Are Essential

For manufacturers prioritizing throughput and sustainability, hinge chip conveyors deliver unmatched ROI. Facilities report an average 14-month payback period through waste reduction and productivity gains. As machining tolerances tighten globally, these systems will remain critical for maintaining competitive edge.

(hinge chip conveyor)

FAQS on hinge chip conveyor

Q: What is a hinge chip conveyor?

A: A hinge chip conveyor is a mechanical system used to remove metal chips and debris from machining tools. It consists of hinged steel belts that transport waste efficiently. This design ensures durability and smooth operation in industrial settings.

Q: How does a hinge chip conveyor differ from other metal chip conveyors?

A: Unlike drag or magnetic conveyors, hinge chip conveyors use interlocking hinged plates to handle heavy, sharp metal chips. They excel in high-volume, high-temperature environments. Their robust construction minimizes wear and tear.

Q: What industries commonly use hinge chip conveyors?

A: Hinge chip conveyors are widely used in metalworking industries like automotive, aerospace, and manufacturing. They are ideal for CNC machines, lathes, and milling operations. Their versatility suits both wet and dry chip removal.

Q: Why choose a metal chip conveyor over manual waste removal?

A: Metal chip conveyors automate waste disposal, improving workplace safety and efficiency. They reduce downtime caused by manual cleaning and prevent equipment damage. This leads to higher productivity and lower labor costs.

Q: What maintenance does a hinge chip conveyor require?

A: Regular inspection of hinges, belts, and drive mechanisms is essential. Lubrication and clearing jammed debris ensure longevity. Periodic alignment checks prevent operational disruptions.