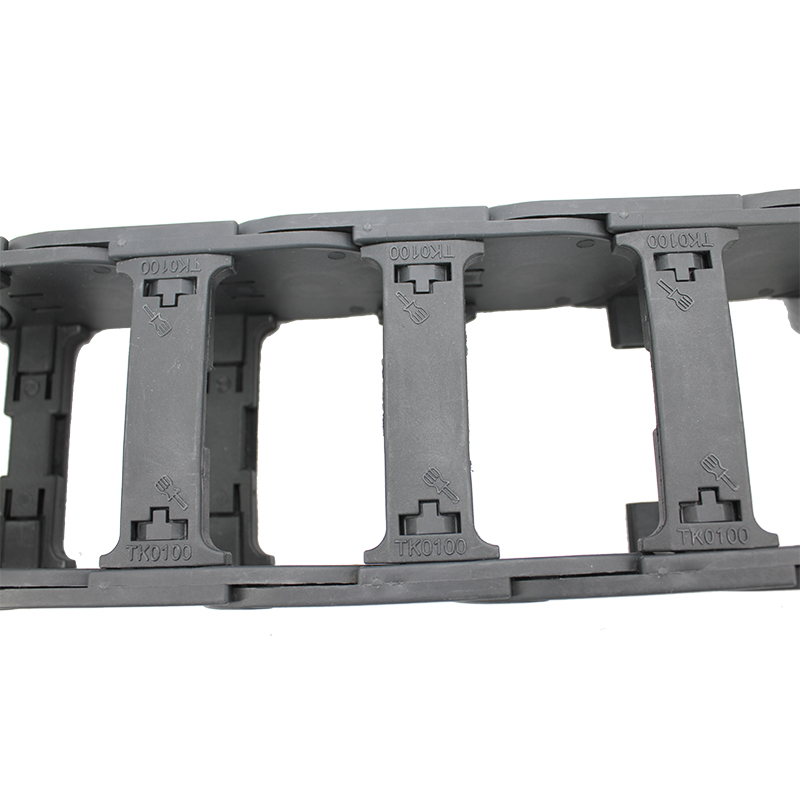

High Strength Drag Chain for Enhanced Durability and Performance in Industrial Applications

High Tensile Drag Chains Essential Solutions for Modern Industry

In the realm of industrial automation and machinery, the efficiency and effectiveness of operations often hinge on the choice of components that manage power and data transmission. One of the most critical components in this regard is the drag chain, particularly high tensile drag chains. These specially designed systems play a vital role in ensuring smooth and reliable operations across various applications, ranging from manufacturing to robotics.

What Are High Tensile Drag Chains?

High tensile drag chains are robust structures engineered to house and protect cables, hoses, and other flexible elements. These chains are typically composed of high-strength materials, allowing them to withstand considerable stress and strain. Unlike standard drag chains, high tensile variants are particularly fit for challenging environments where heavy loads and dynamic movements are prevalent. Their design aims to offer enhanced durability, resistance to wear and tear, and the capacity to handle high tension and pressure.

Applications of High Tensile Drag Chains

The application of high tensile drag chains spans multiple sectors, including

1. Manufacturing In factories, high tensile drag chains facilitate the movement of robotic arms, conveyors, and other machinery. They ensure that power and signal cables are neatly organized and protected, minimizing the risks of tangling or damage during operation.

2. Automotive Industry The automotive sector often relies on high tensile drag chains for production lines where precision and efficiency are paramount. These chains help manage the myriad of hoses and wires in assembly lines, ensuring smooth functionality and safety.

3. Aerospace and Aviation In aerospace applications, where reliability is critical, high tensile drag chains are used to protect crucial systems that control flight mechanisms and onboard systems. The extreme conditions encountered in aviation demand components that can withstand intense stress, making high tensile drag chains indispensable.

4. Robotics Modern robotics relies heavily on these drag chains for the seamless operation of articulated arms and automated systems. High tensile drag chains support the flexible movements of robotic joints, enabling them to perform complex tasks with ease.

high tensile drag chain

Advantages of High Tensile Drag Chains

Opting for high tensile drag chains comes with several advantages

- Durability Constructed from high-strength materials, these chains offer exceptional longevity. They can endure harsh environmental conditions, resist abrasions, and maintain functionality under significant load.

- Flexibility High tensile drag chains are designed to accommodate various cable types and configurations, contributing to organizational efficiency and reducing clutter in industrial settings.

- Safety By encasing cables and hoses, drag chains prevent accidents related to entangled wires, thereby enhancing workplace safety.

- Efficiency The efficient management of cables and hoses results in streamlined operations. The reduced risk of damage minimizes downtime, boosting productivity.

Installation and Maintenance

While high tensile drag chains offer numerous benefits, proper installation and regular maintenance are essential to ensure their longevity and effectiveness. Installation must adhere to the manufacturer’s guidelines, considering factors such as movement range and load capacity. Additionally, periodic inspections can help identify wear and tear, allowing for timely replacements and repairs.

Conclusion

High tensile drag chains represent a vital innovation in industrial design, addressing the need for efficiency, safety, and reliability in power and data transmission systems. Their applications across multiple sectors underline their versatility and importance in modern manufacturing and automation processes. As industries continue to evolve, the role of high tensile drag chains will undoubtedly grow, positioning them as essential components of future technological advancements. Investing in high tensile drag chains not only enhances operational capabilities but also contributes significantly to the overall safety and productivity of industrial environments.