High Strength Drag Chains for Enhanced Load Management and Durability in Industrial Applications

High Tensile Drag Chains A Comprehensive Overview

In the realm of industrial automation and machine operation, the significance of drag chains cannot be overstated. One of the most advanced types available in the market today is the high tensile drag chain. Designed to manage and protect various cables and hoses in a multitude of applications, these chains have transformed the way industries handle material movement and automation processes.

What are Drag Chains?

Drag chains, also referred to as cable carriers or energy chains, are systems used to guide and protect cables and hoses when they are in motion. They are commonly employed in environments where machinery or equipment requires mobility, such as in CNC machines, robotics, and conveyor systems. The primary function of a drag chain is to keep cables organized and prevent tangling or damage caused by friction and wear.

The Importance of High Tensile

High tensile drag chains are made from materials that can withstand significant stress and strain. They are engineered to provide superior strength and durability, ensuring they can support heavy loads without deformation or failure. The high tensile quality is essential in applications where considerable tension is applied, making these chains ideal for scenarios involving high-speed movement or frequent stops and starts.

With the increasing demands for automation and efficient material handling, the role of high tensile drag chains has become more crucial. These chains are tailored to endure harsh working conditions, including exposure to chemicals, extreme temperatures, and abrasive environments, further enhancing their appeal in various industries.

Key Benefits of High Tensile Drag Chains

1. Enhanced Durability The reinforced structure of high tensile drag chains enables them to withstand wear and tear over extended periods. This durability translates to lower maintenance costs and less downtime for machinery.

2. Flexibility and Versatility High tensile drag chains come in various sizes and designs, allowing for customization based on specific application requirements. They can accommodate multiple cables and hoses, making them suitable for a wide range of machines.

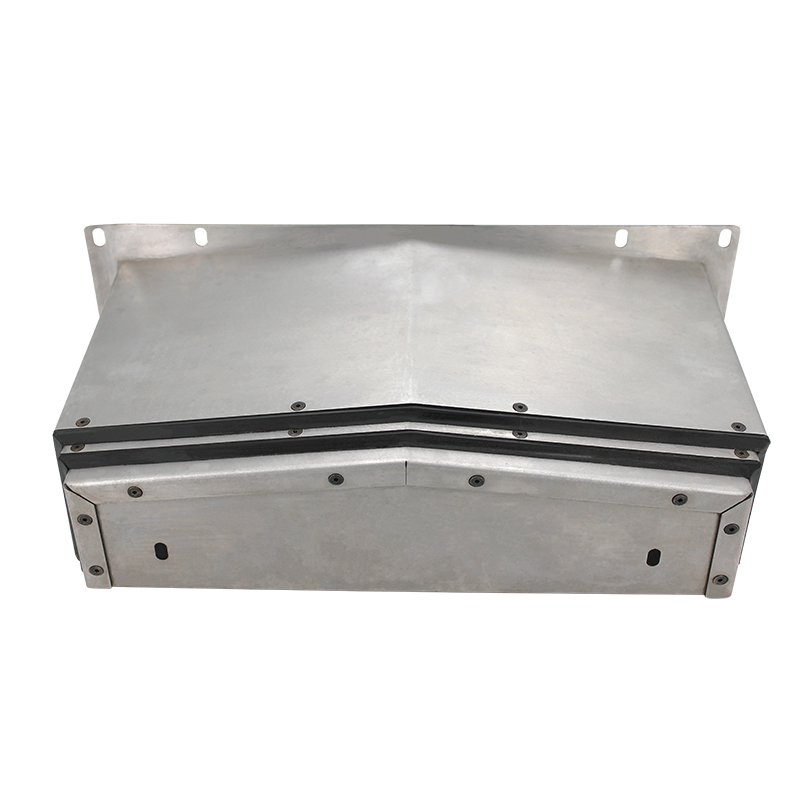

high tensile drag chain

3. Improved Safety By securely routing cables and hoses, drag chains reduce the risk of entanglement or damage during operation. This safety feature is particularly vital in automated systems where movement is rapid and unpredictable.

4. Reduced Friction and Noise These chains minimize friction between moving parts, leading to a quieter operation. This benefit is especially important in environments where noise levels can impact workers’ health and productivity.

5. Cost-Effectiveness Investing in high tensile drag chains can lead to significant long-term savings. Their ability to prolong the lifespan of cables and hoses reduces replacement frequency, thereby lowering overall operational costs.

Applications of High Tensile Drag Chains

High tensile drag chains are widely used across various sectors, including

- Manufacturing In production lines where conveyors and robotic arms are utilized, these chains help manage the extensive wiring required for power and data transfer. - Automotive Industry High tensile drag chains provide reliable cable management in assembly lines, ensuring that the various components of vehicles can move efficiently.

- Mining and Heavy Equipment The chains’ robustness makes them ideal for extreme environments, where durability is critical for uninterrupted operation.

- Aerospace In aircraft manufacturing and maintenance, high tensile drag chains assist in managing the complex systems of cables necessary for navigation and communication.

Conclusion

High tensile drag chains represent a significant advancement in the field of cable management for dynamic environments. Their durability, versatility, and safety features make them invaluable to various industries, contributing to enhanced operational efficiency and lower costs. As technology and automation continue to evolve, the importance of high-quality drag chains will only become more prominent, emphasizing the need for industries to invest in reliable solutions that support their growth and sustainability. To ensure smooth and efficient operation in any application, choosing high tensile drag chains is undoubtedly a step in the right direction.