High Temperature Split Loom Tubing for Enhanced Wire Protection and Management Solutions

High Temperature Split Loom Tubing A Comprehensive Overview

In the realm of electrical and mechanical applications, cable management is a pivotal aspect that cannot be overlooked. Among various options available, high temperature split loom tubing stands out as a preferred solution for protecting and organizing cables and wires. This article will explore the significance, benefits, and applications of high temperature split loom tubing, as well as factors to consider when selecting the right product for your needs.

What is High Temperature Split Loom Tubing?

High temperature split loom tubing is a protective covering made from materials designed to withstand elevated temperatures, usually ranging from 176°F (80°C) to over 400°F (200°C), depending on the specific type of tubing. The split design allows for easy installation, as it can be opened along one side to accommodate wires and cables without needing to disconnect them. This feature is particularly advantageous in environments where reconfiguring wiring is cumbersome or impractical.

The Importance of High Temperature Resistance

The ability of split loom tubing to endure high temperatures is critical in several industries, including automotive, aerospace, manufacturing, and electronics. In these sectors, wires and cables are often subjected to extreme conditions, which can lead to insulation breakdown, shorts, and electrical failures if not adequately protected. High temperature split loom tubing mitigates these risks by providing a robust barrier that guards against heat, abrasion, chemicals, and other potential hazards.

Benefits of High Temperature Split Loom Tubing

1. Enhanced Protection The primary advantage of using high temperature split loom tubing is its protective nature. It shields wires from heat damage, preventing insulation from melting or degrading, which can subsequently lead to electrical malfunctions.

2. Ease of Installation The split design of this tubing simplifies the process of enclosing cables and wires. Users can easily place the tubing over existing cables without the need for connectors or additional tools, making it a convenient choice for quick installations.

3. Versatile Applications High temperature split loom tubing is versatile and can be used in a multitude of settings. It is suitable for automotive engine compartments, industrial machinery, aircraft systems, and even household appliances that generate significant heat.

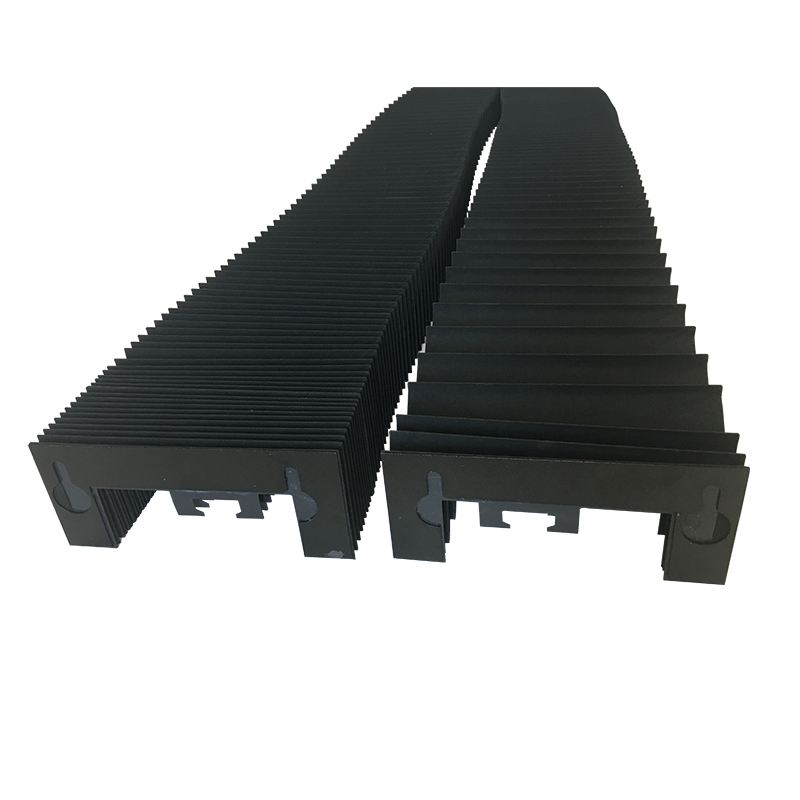

high temp split loom tubing

5. Durability Made from sturdy materials such as polyethylene or ABS plastic, high temperature split loom tubing is resistant to wear and tear. This durability ensures long-term performance, making it a cost-effective solution for many projects.

Applications of High Temperature Split Loom Tubing

1. Automotive Industry In vehicles, high temperature split loom tubing is commonly used to protect wiring harnesses under the hood where temperatures can soar. It is also beneficial in preventing damage from engine vibrations and exposure to chemicals.

2. Aerospace and Aviation The aerospace sector relies heavily on high temperature tubing to safeguard sensitive electrical systems located in the engine and fuselage, where extreme heat and corrosive environments are prevalent.

3. Manufacturing and Industrial Settings In factories and production lines, high temperature split loom tubing protects wiring associated with machinery that operates at high temperatures, thus ensuring worker safety and equipment longevity.

4. Electronics Within electronic devices, where overheating can cause significant performance issues, this tubing provides an extra layer of insulation to prevent failure.

Choosing the Right High Temperature Split Loom Tubing

When selecting high temperature split loom tubing, consider the following factors

- Temperature Rating Ensure that the tubing can withstand the temperatures specific to your application. - Size and Diameter Match the size of the tubing to the diameter of the cables or wires you need to protect. - Material Properties Review the material specifications for chemical resistance and durability to suit your environment.

Conclusion

High temperature split loom tubing is an indispensable component in various industries, providing essential protection and organization for cables and wires exposed to extreme conditions. Its exceptional durability, ease of installation, and ability to prevent damage make it a favored choice among professionals. As technology evolves and applications become more demanding, the role of high temperature split loom tubing is only destined to grow, making it a critical investment for safeguarding electrical systems in a wide range of environments.