High Tensile Drag Chain - Durable and Reliable Solutions for Your Needs

High Tensile Drag Chains Essential Components for Modern Machinery

In today’s industrial landscape, efficiency and durability are paramount. One component that plays a crucial role in ensuring optimal performance in machinery is the high tensile drag chain. Often overlooked, drag chains are essential for organizing and protecting cables and hoses that power and control various equipment, from robotics to conveyor systems.

High tensile drag chains are specifically designed to withstand significant stress and strain in demanding environments. Made from advanced materials with high tensile strength, these chains ensure that cables and hoses remain securely in place, minimizing wear and tear. This durability is especially important in applications involving heavy machinery or where chains are subject to constant movement.

The primary function of a drag chain is to guide and protect cables and hoses as they move with machinery. For instance, in CNC machines or robotic arms, the drag chain allows for smooth movement while preventing tangling or damage to vital lines. As these machines operate, the drag chain effectively manages the dynamic movements, ensuring that the cables have the necessary slack without compromising safety or performance.

One of the standout features of high tensile drag chains is their ability to operate in harsh environments. Many industries, such as manufacturing, construction, and aerospace, expose machinery to extreme conditions, including high temperatures, chemicals, and abrasive materials. High tensile drag chains are designed to resist these factors, extending their operational lifespan and reducing the need for frequent replacements—a significant cost-saving benefit for businesses.

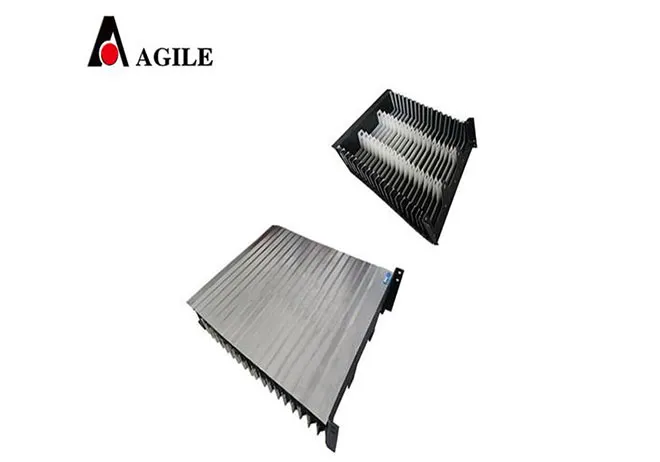

high tensile drag chain

Moreover, high tensile drag chains contribute to the overall safety of machinery

. By securely enclosing cables and hoses, they prevent accidental tripping hazards and electrical malfunctions that could arise from loose or damaged lines. This is particularly crucial in environments where workers are present, as safety is always a top priority.Customization is another advantage of high tensile drag chains. Manufacturers offer various sizes, shapes, and configurations to meet the specific needs of different applications. Whether the requirement is for compact designs in tight spaces or larger chains for extended reach, there are options available to suit various operational demands. This flexibility allows industries to optimize their setups without compromising on design or functionality.

In addition to their mechanical benefits, high tensile drag chains also contribute to a more organized workplace. Efficient cable management not only improves the aesthetics of machinery but also enhances overall productivity by making maintenance and repairs easier. Technicians can quickly identify and address issues without the added complexity of tangled cables, thereby reducing downtime.

In conclusion, high tensile drag chains are indispensable components that support the functionality and safety of modern machinery. Their ability to protect and efficiently manage cables and hoses in harsh environments makes them a vital part of industrial operations. As industries continue to evolve and push the limits of technology, the importance of high tensile drag chains will only grow, cementing their status as key players in the field of mechanical engineering. Investing in quality drag chains is not just a choice, but a necessity for businesses aiming to enhance efficiency and safety in their operations.