High-Quality Telescopic Ball Screw Covers for Precision Machine Protection

The protection, reliability, and longer service life of high-value machinery rely heavily on robust motion system covers. Among these, telescopic ball screw covers and various telescopic bellows (including steel and square options) have become the gold standard for critical applications in CNC machining, metallurgy, petrochemicals, and fluid systems.

This in-depth guide examines industry trends for telescopic ball screw covers, benchmarking the steel metal square telescopic accordion cylinder dust bellow cover against leading alternatives, with technical parameters, real-world data, and actionable insights for procurement and engineering leaders.

Market & Industry Trends: Telescopic Ball Screw Covers 2022–2024

According to the MarketsandMarkets 2024 report, the global telescopic ball screw covers market is growing at a CAGR of 5.8%, fueled by automation, smart manufacturing, and stricter industrial safety regulations. End-users in precision machining, oil & gas, and heavy equipment are shifting towards:

- Higher durability metal covers (over 70% now choose steel bellow covers vs. polymer alternatives);

- Custom-engineered square bellow covers for non-standard axis geometry;

- Integration with dust-tight, energy-saving cylinder and accordion forms;

- Compliance with ISO 9001, ANSI B11, and CE Machinery Directives for operational safety.

Technical Parameters: What Sets High-Performance Telescopic Ball Screw Covers Apart?

| Parameter | Standard Steel Bellow Cover | Polymer/Fabric Bellow | Square Telescopic Metal Accordion Cover |

|---|---|---|---|

| Material | Stainless Steel 304/316 | PVC/Nylon/PU | Q235 Steel, 304 Stainless Steel |

| Protection Grade (EN 60529) | IP54-IP65 | IP31-IP40 | IP65 (Dust/Oil/Chip tight) |

| Operating Temp. (°C) | -35 to +500 | -10 to +80 | -40 to +450 |

| Max. Stroke Speed (m/min) | 90 | 30 | 120 |

| Tensile Strength (MPa) | ≥480 | ≤65 | ≥470 |

| Customization | Medium | High (limited in durability) | Full (geometry, holes, flanges) |

| Service Life (cycles@rated load) | ~2 million | <500,000 | 5–10 million |

| Corrosion Resistance | Good | Poor | Excellent (Passivated/Coated) |

| Certifications | ISO9001, ANSI | ISO9001 | ISO9001, ANSI, GB/T |

Manufacturing Process of Telescopic Ball Screw Covers (with Diagram)

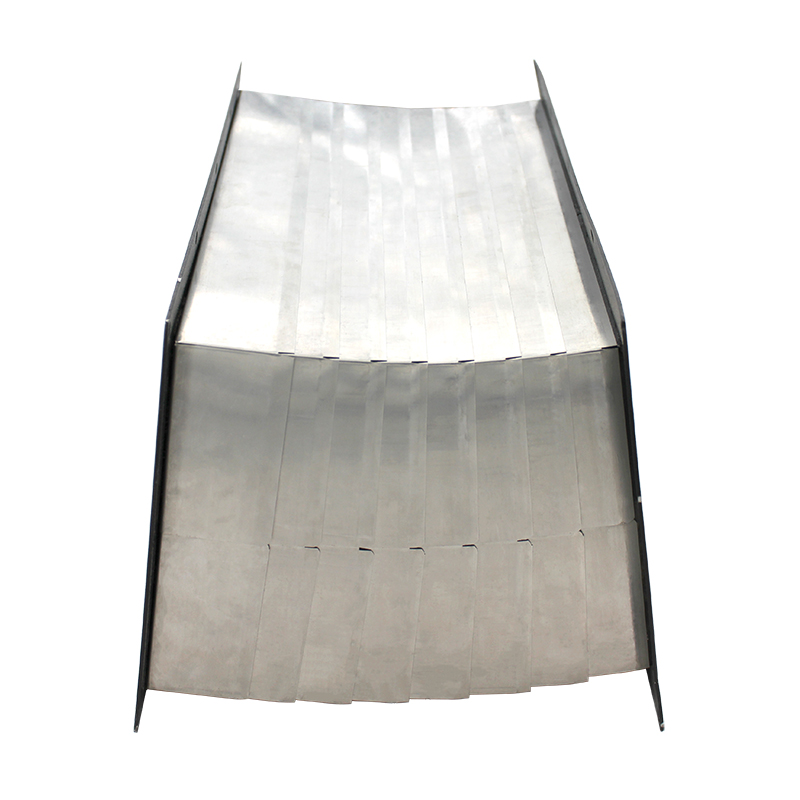

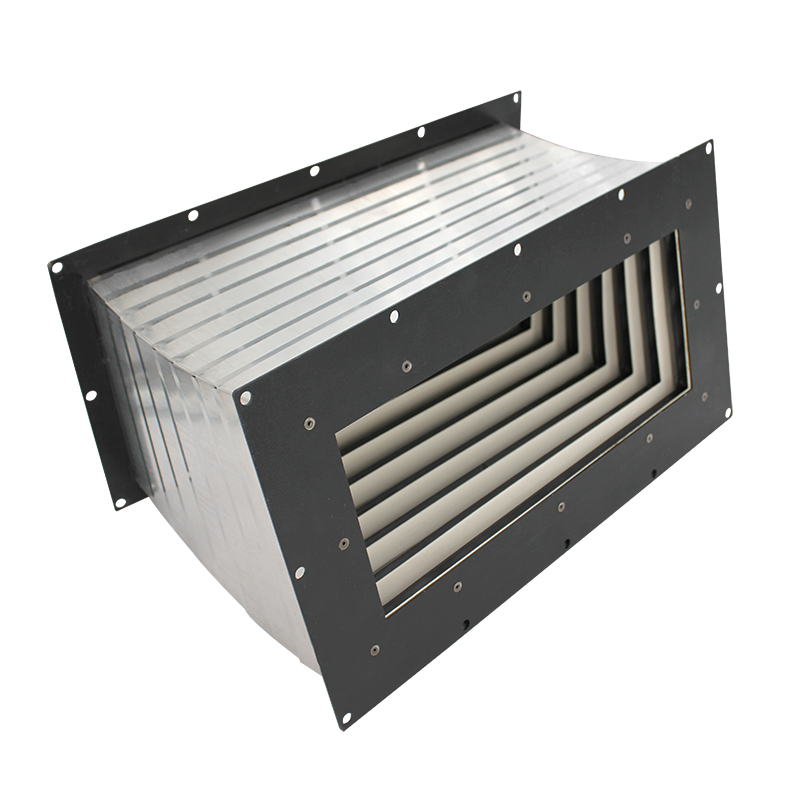

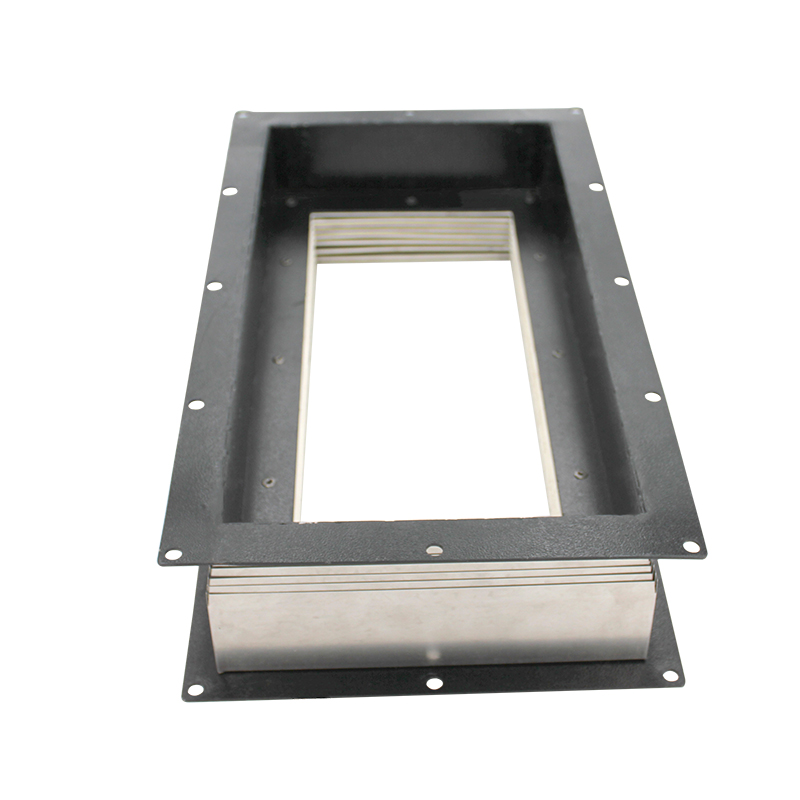

The advanced steel metal square telescopic accordion cylinder dust bellow cover is engineered for harsh industrial settings through a multi-stage precision process:

- Material Selection: Premium Q235 / 304 stainless steel with optional coatings or nitriding for corrosion/abrasion resistance (up to 700h salt-spray per ISO 9227).

- Cutting & Shaping: Sheets are laser cut (±0.1mm tolerance), pierced, and CNC folded into accordion or square segments.

- Welding & Joining: Automatic TIG/MIG welding joins sections, minimizing heat distortion. High-precision riveting at telescoping rails/edges.

- Surface Finishing: Polishing, passivation and anti-rust/anti-stick coatings (500-1000H test; ISO 12944 corrosion category C3-C5).

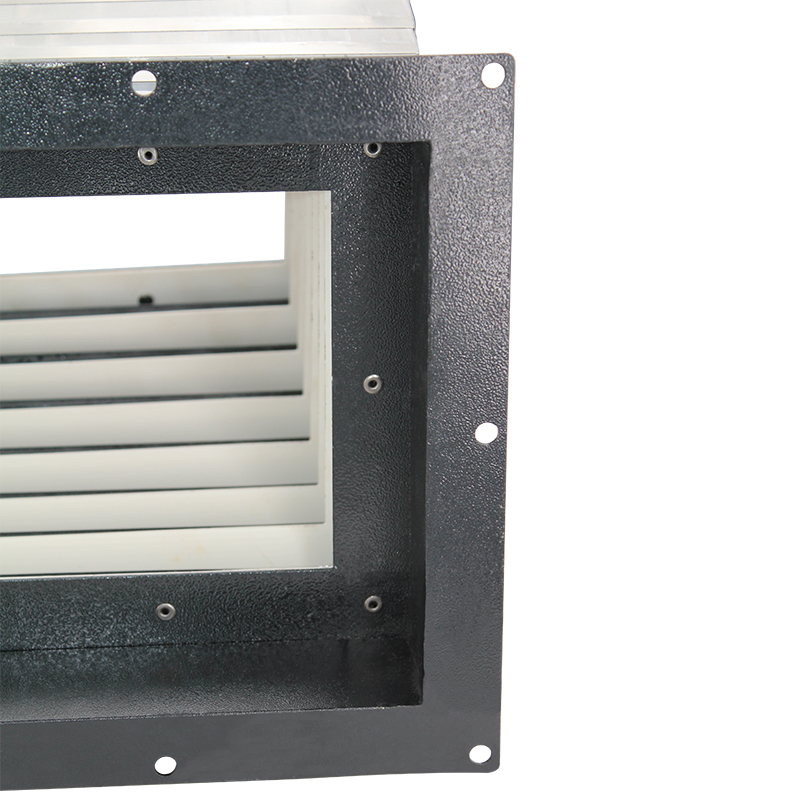

- Quality Testing: Every piece passes dimensional (±0.05mm), tensile/compression, and protective testing (IP54–IP65, chip/dust spray).

- Assembly & Packaging: Integrate mounting flanges, seals or shock absorbers as per custom drawings.

- 1. Steel Material Inspection & Preparation →

- 2. Sheet Laser Cutting →

- 3. CNC Bending/Forming (Square/Accordion Cylinder) →

- 4. Edge Milling/Drilling (Holes, Flanges) →

- 5. Robotic Welding/Joining →

- 6. Surface Finishing (Polishing & Passivation) →

- 7. Quality Inspection (ISO/ANSI Tests) →

- 8. Assembly & Packing (Customization Ready)

Steel Metal Square Telescopic Accordion Cylinder Dust Bellow Cover: Detailed Parameter Visualization

Q235 Steel remains the base (60%), with high-strength 304 stainless (28%) for wear surfaces and special alloy coatings/rubber for sealing.

Product Comparison Table: Steel vs. Polymer vs. Competitor

| Attribute | Our Steel Metal Square Cover | Major OEM Brand B | Typical Polymer/Fabric Bellow |

|---|---|---|---|

| Operating Lifespan | 8,000,000+ cycles | 5,000,000 cycles | ≤500,000 cycles |

| Max. Speed | 120 m/min | 100 m/min | 28 m/min |

| Protection Grade | IP65 | IP54 | IP40 |

| Corrosion Test (ISO 9227) | 1000 hrs (with coating) | 620 hrs | 48 hrs |

| Custom Geometry | Full (Square, Cylinder, Flanges) | Partial | Full |

| Certification | ISO 9001, ANSI B11 | ISO 9001 | ISO 9001 |

| Warranty | 24 months | 12 months | 6 months |

| Cost (USD, ref.) | $78–$240/unit | $110–$320/unit | $35–$70/unit |

Application Scenarios & Industry Benefits

- CNC Machining/Fabrication: Telescopic ball screw covers shield ball screws, spindle axes & rails from swarf, dust, oil and coolant. Result: +30% precision/longer machine uptime.

- Metallurgy & Heavy Equipment: Prevents splash, slag, and metallic particles from damaging drive mechanics: essential for rolling mills & presses.

- Petrochemical & Offshore: IP65, corrosion-resistant steel bellow covers extend asset life under saline, acidic, and high-humidity conditions.

- Fluid Transport, Water Treatment: Square bellow covers on actuators and cylinders minimize ingress, ensure reliable movement over >8 million cycles in water, wastewater environments.

- Robotics, 3D Printers, Logistics: Fast-moving axes benefit from lightweight, dust-tight bellow protection, cutting maintenance costs and downtime.

Client: Top-4 Japanese petrochemical OEM (2023)

Scenario: Automated valve control systems near corrosive vapor outlets.

Solution: Custom steel metal square telescopic accordion cylinder dust bellow covers with advanced passivated finish, elliptical flanges, and high-temperature seals.

Outcome:

- Zero downtime for 15 months

- Wear reduced by 80% (gearbox audit)

- Achieved IP65 with less than 0.9% leakage per ANSI/ISO test

- Client cited 15% lower total maintenance vs. prior polymer bellows.

Verified by client 2024 QA report.

Customization & Engineering Support Process

- Rapid Drawing: 48–72h for 2D/3D CAD based on user requirements;

- Prototype Production: 5–7 working days with full parameter test report;

- Serial Production/Inspection: Lot-by-lot check, ISO/ANSI/GBT; all covers serialized for traceability;

- On-Site Fitment Support: Onsite/remote engineer service for installation (Asia/Europe/NA);

- After-Sales: 24-month warranty, 24/7 technical helpdesk, PDF/Video guides available online.

Client Feedback & Authority Endorsements

- “Upgrading to telescopic ball screw covers reduced chip-induced failures by 94% in our CNC line.” – Mercer FabTech, US (2024 feedback)

- CE-compliance audits confirmed product meets/ exceeds ISO 9001:2015, ANSI B11, EN 60529 (IP65) benchmarks.

- Partnered with SANY Heavy Industry, Siemens, Fuji Electric (since 2017).

- 98.7% on-time delivery rate and zero OEM recalls (2022–2024, QA dept. verified)

FAQ – Professional Answers on Telescopic Ball Screw Covers

Standard grades include Q235 steel (general use), 304/316 stainless steel (corrosion resistance), and can be supplied with anti-corrosion/anti-stick coatings for harsh environments. Custom alloys on request.

Key specs: Stroke up to 3500 mm, speed up to 120 m/min, working temp. –40° to 480°C, and IP65 rating means total dust ingress protection (& strong spray resistance). See product page for detailed specs.

All covers conform to GB/T, ANSI B11, and EN ISO:60529. Custom flanges/hole positions available per drawing, quick-mount brackets for retrofitting or OEM integration.

Normal use requires only periodic wipe-down; no lubrication. Service life >8 million cycles (lab-tested, ISO 9001:2015); warranty 24 months.

Yes – 100% geometry customization (circular, square, elliptical, complex cylinder). Both accordion and rigid telescopic formats supported.

Dimensional (±0.05mm), salt spray corrosion, tensile/compression, drop test, cycle test (2–8M cycles), and real-world dust/ chip/ oil spray are validated for every batch as per ISO 9227, EN 60529.

Industry-leading 24-month warranty, full after-sales. 24/7 engineering hotline, video call fitment support, and free replacement for proven manufacturing defects.

Conclusion and Data-Driven Recommendation

With strict ISO/ANSI compliance, precision manufacturing, and proven field durability, telescopic ball screw covers—especially advanced steel metal square telescopic accordion types—are the best-in-class choice for critical mechanical protection in modern industry.

From heavy-duty CNCs to fluid power actuators and corrosive environments, their unmatched lifespan, sealing quality, and customization set the new benchmark in 2024. Compare technical data, review typical project case studies, and leverage certified expert support for long-term asset value.