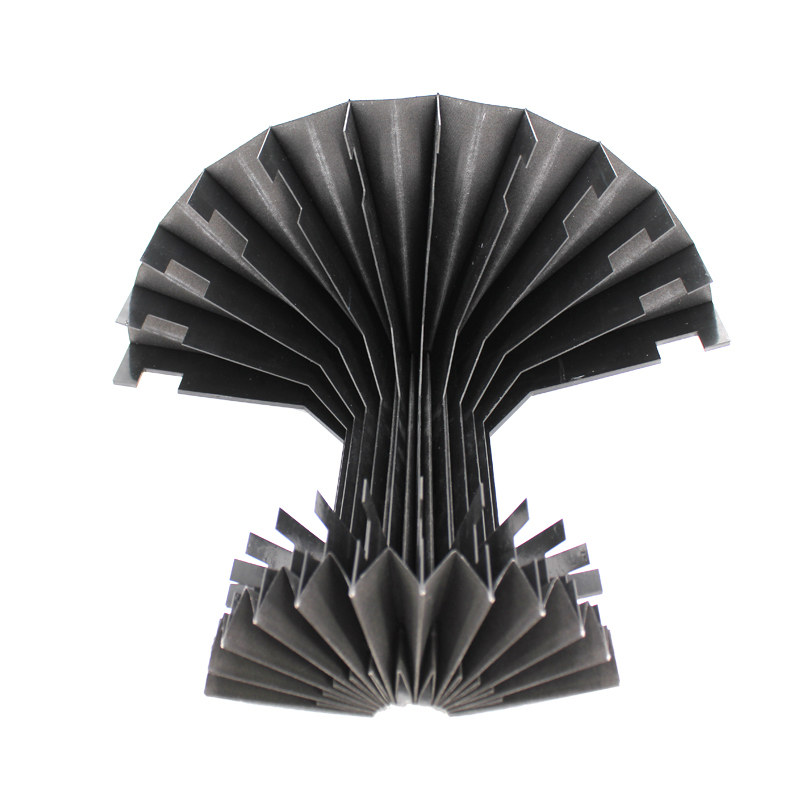

heavy duty corrugated conduit

The Essential Guide to Heavy Duty Corrugated Conduit

In the realm of electrical installations and cable management, choosing the right conduit is crucial for ensuring safety, durability, and functionality. Among the various types of conduits available, heavy duty corrugated conduit stands out as a robust solution tailored for harsh environments and demanding applications. This article explores the unique properties, benefits, and applications of heavy duty corrugated conduit, as well as best practices for installation and maintenance.

Understanding Heavy Duty Corrugated Conduit

Heavy duty corrugated conduit is a type of electrical tubing made from high-quality materials, commonly polyvinyl chloride (PVC) or polyethylene. Its corrugated design offers flexibility and strength, making it ideal for protecting electrical wires and cables in various settings. The conduit’s structure allows it to withstand significant mechanical stress while maintaining an effective shield against water, chemicals, and other environmental factors.

The heavy duty designation indicates that this conduit is engineered for applications that require increased resistance to impact, corrosion, and abrasions. As such, it finds extensive use in both indoor and outdoor environments, including industrial sites, construction zones, and residential areas.

Benefits of Heavy Duty Corrugated Conduit

1. Durability and Longevity Heavy duty corrugated conduit is designed to provide long-lasting protection for electrical cables. Its robust construction minimizes wear and tear, which is particularly important in environments with high movement or exposure to harsh elements.

2. Flexibility The corrugated design permits a degree of flexibility, allowing installers to navigate tight spaces and curves without compromising the integrity of the conduit. This flexibility also aids in reducing installation challenges, making it easier to route cables through complex electrical systems.

3. Resistance to Environmental Factors This conduit type is highly resistant to moisture, chemicals, and UV radiation. As such, it is an excellent choice for outdoor applications where exposure to the elements is a concern. Additionally, its resistance to corrosion ensures that it remains intact and functional over time.

4. Safety Features Heavy duty corrugated conduit provides a critical safety function by protecting electrical wiring from physical damage and environmental hazards. This is especially vital in industrial settings where the risk of impacts or chemical spills is higher.

heavy duty corrugated conduit

5. Cost-Effectiveness Although heavy duty corrugated conduit may come at a higher initial cost compared to standard conduits, its durability and reduced need for replacement make it a cost-effective choice in the long run. This investment pays off by minimizing downtime and maintenance expenses.

Applications

Heavy duty corrugated conduit is versatile and is commonly used in numerous applications across various industries

- Industrial Facilities It is widely used in factories and manufacturing plants to protect power and control cables from mechanical damage and harsh chemicals. - Construction Sites During new construction, heavy duty conduits are essential for safeguarding electrical installations from potential hazards. - Underground Installations Its resilience makes it suitable for underground applications, where moisture and soil can pose significant risks to electrical cables. - Outdoor Lighting and Signage The conduit is often employed in outdoor electrical systems, ensuring that connections are protected from the elements. - Agriculture and Livestock In agricultural settings, especially where machinery operates and animals are housed, heavy duty conduits safeguard critical electrical lines.

Installation and Maintenance

When installing heavy duty corrugated conduit, it is essential to follow best practices to maximize its protective benefits. First, ensure that the conduit is cut to the appropriate length and that all edges are smooth to prevent potential damage to the cables. Use appropriate fittings and connectors to maintain a secure and watertight seal.

Regular maintenance checks should be conducted to identify any signs of wear or damage. Inspect the conduit periodically for cracks, warping, or other vulnerabilities that may compromise the protection of the electrical system. If any damage is detected, prompt replacement is recommended to ensure the continued safety and functionality of the installation.

Conclusion

Heavy duty corrugated conduit represents a vital component in the protection and management of electrical systems in a wide array of environments. Its strength, flexibility, and resistance to environmental factors make it an ideal choice for demanding applications. By understanding its benefits and applications, as well as adhering to best installation and maintenance practices, individuals and businesses can enhance the safety and longevity of their electrical installations. Choosing heavy duty corrugated conduit not only protects electrical cables but also contributes to a safer and more efficient operational environment.