heat resistant split loom

Understanding Heat Resistant Split Loom Protecting Your Cables

In today's fast-paced world, electrical installations and wiring are pivotal to nearly every industry, from automotive to aerospace and home appliances. As technology evolves, the demand for effective cable management solutions has never been greater. One critical component in this realm is the heat-resistant split loom, a protective tubing designed to safeguard wiring from environmental hazards.

What is a Heat Resistant Split Loom?

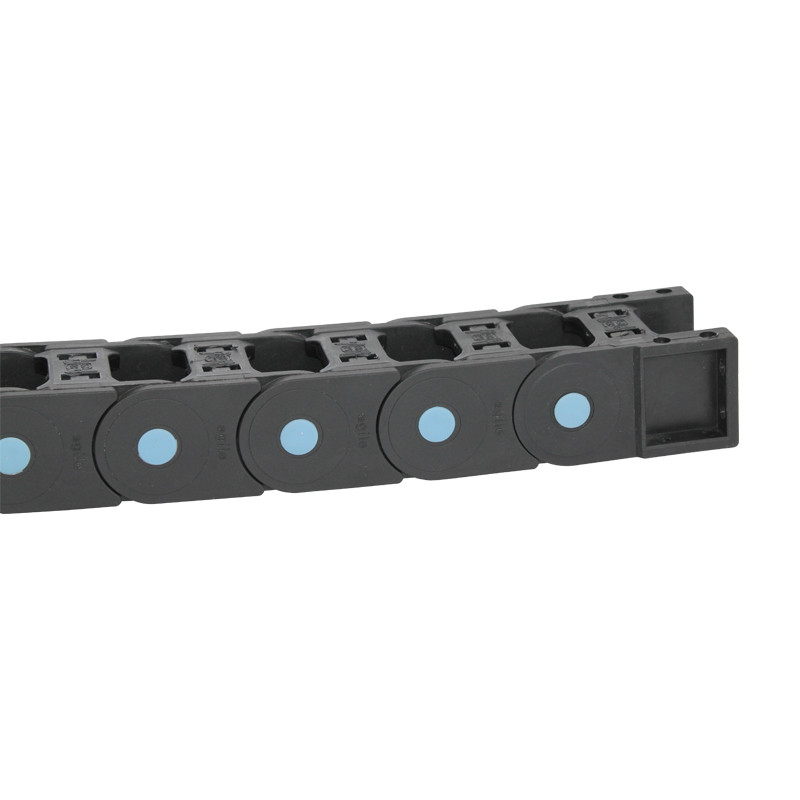

A heat-resistant split loom is a type of tubing used to encase and protect wires and cables, particularly in applications subjected to high temperatures. Made from durable materials such as polyamide or polyethylene, these split looms can withstand extreme heat, making them ideal for use in environments where traditional tubing might fail.

The design of the split loom is particularly advantageous because it allows for easy installation and maintenance. Featuring a longitudinal split running the length of the loom, users can easily insert wires without the need to disconnect existing connections. This design also enables quick removal or replacement of cables, which is essential for troubleshooting and repairs.

Why Use Heat Resistant Split Loom?

1. Protection Against Heat One of the main advantages of using heat-resistant split loom is its ability to protect cables from high temperatures. In industries like automotive or aerospace, where engines and machinery can generate significant heat, utilizing this protective tubing minimizes the risk of wire insulation melting or becoming damaged.

heat resistant split loom

2. Mechanical Protection Beyond thermal resistance, these split looms also provide robust mechanical protection. They shield wires from abrasion, cutting, and other physical damages that can occur in rugged environments. This added layer of protection can drastically reduce the chances of electrical failures or short circuits.

3. Flexibility and Versatility The versatility of heat-resistant split loom makes it a go-to choice for many applications. Available in various diameters and lengths, it can accommodate different wire sizes and configurations. Whether used in automotive wiring harnesses, industrial machinery, or home electrical systems, it adapts to diverse needs.

4. Improved Aesthetics and Organization Using split loom helps maintain a tidy and organized wiring setup. It conceals unsightly wires and reduces clutter, presenting a more professional appearance in electronic installations. This not only enhances the aesthetic appeal but also makes navigation easier during maintenance and repairs.

Installation Tips

Installing heat-resistant split loom is straightforward. Simply cut the desired length of the loom, split it open, and insert the wires. Ensure that the ends are secured to prevent dust and moisture infiltration, which could compromise the integrity of the wiring. For applications exposed to higher temperatures, it’s wise to verify that the selected loom matches the thermal requirements of the environment.

Conclusion

Heat-resistant split loom offers an indispensable solution for safeguarding electrical wiring in high-temperature applications. By providing excellent thermal and mechanical protection while allowing easy cable management, it plays a crucial role in enhancing the longevity and reliability of wiring systems. As industries continue to evolve, the importance of such protective solutions cannot be overstated, making heat-resistant split loom a critical component in modern cable management strategies. Whether for professional or DIY projects, investing in quality split loom ensures reliable performance in the face of heat and wear.