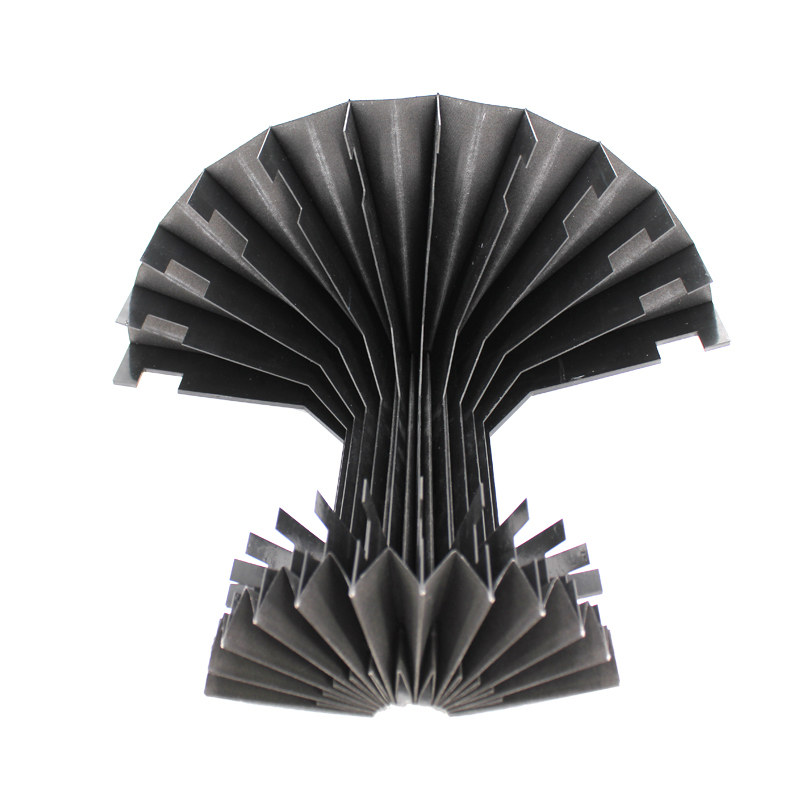

flexible drag chain

Understanding Flexible Drag Chains A Comprehensive Guide

In the realms of modern automation, manufacturing, and machine design, the concept of flexible drag chains has emerged as an essential component that ensures mechanical efficiency and longevity. These systems, designed to protect and manage cables, hoses, and other moving parts in machinery, are particularly valuable in applications that necessitate dynamic movement and flexibility.

What are Flexible Drag Chains?

Flexible drag chains, also known as cable carriers or energy chains, are series of interconnected links that hold cables, hoses, and tubes securely. They are engineered to allow these components to move freely without tangling or becoming damaged. By organizing wiring and preventing wear, flexible drag chains contribute to more streamlined operations and reduced downtime.

Key Advantages of Flexible Drag Chains

1. Protection These chains shield sensitive cables and hoses from abrasion, moisture, and environmental damage. This protection is crucial in heavily industrial contexts where equipment is exposed to harsh conditions.

2. Flexibility True to their name, flexible drag chains can move in multiple directions. They are designed to bend and flex without putting excessive strain on the components within them, making them ideal for applications like robotics, CNC machines, and even packaging lines.

3. Ease of Maintenance With well-organized cables, troubleshooting and maintenance become significantly easier. Identifying and replacing faulty cables is expedited, minimizing downtime for repairs.

4. Customization Flexible drag chains can be tailored for specific applications. Manufacturers offer a diverse range of sizes, materials, and configurations, allowing industries to select options that best fit their unique needs.

5. Cost Efficiency Though the initial investment may be considerable, flexible drag chains can lead to significant savings over time. By prolonging the lifespan of cables and reducing the risks of failure, they help avoid costly repairs and production delays.

Applications of Flexible Drag Chains

Flexible drag chains are ubiquitous in various industries and applications. Here are a few notable uses

flexible drag chain

- Manufacturing Automated production lines heavily utilize drag chains to manage large bundles of wires and hoses. They ensure that the lines remain organized and functional over time, even with constant movement.

- Robotics In robotic applications, flexible drag chains are fundamental in facilitating smooth and unrestricted movement. Cable management is critical to the performance of robotic arms and automated systems, reducing the risk of entanglement.

- Conveyor Systems Drag chains support the electrical wiring and pneumatic hoses in conveyor systems, providing a reliable solution for movement in factories and warehouses.

- CNC Machines These machines benefit from drag chains that protect the numerous cables required for operation, helping maintain operational efficiency in environments that demand precision.

Selecting the Right Flexible Drag Chain

When choosing a flexible drag chain, several factors should be considered

1. Size and Capacity Assess the diameter of the cables or hoses that will be housed within the chain. The chain should provide enough space to accommodate all components without cramming them together.

2. Material Different materials offer different benefits. For instance, plastic chains are lightweight and can resist corrosion, while metal chains may be necessary for high-load applications.

3. Bending Radius Ensure that the drag chain's bending radius matches the application's movement. Chains that are too rigid may lead to damage or failure.

4. Operating Environment Consider factors such as temperature, humidity, and exposure to chemicals when selecting materials and designs.

Conclusion

Flexible drag chains are an invaluable asset in various industrial applications, contributing to improved organization, flexibility, and protection for moving cables and hoses. By investing in the right drag chain, industries can optimize their mechanical systems, enhance productivity, and reduce maintenance costs. With their numerous advantages, flexible drag chains have rightfully earned their place as a cornerstone of modern machinery and automation solutions. Whether in manufacturing or robotics, the functionality and reliability they bring to operations cannot be overstated. As technology continues to advance, flexible drag chains will undoubtedly play a crucial role in supporting innovative designs and operations in the industry.