Versatile Drag Chains for Enhanced Mobility and Flexibility in Various Applications

Understanding Flexible Drag Chains Enhancing Efficiency in Modern Engineering

In today's fast-paced world, industries are constantly seeking innovative solutions to improve efficiency, safety, and functionality. One such innovation is the flexible drag chain, a critical component in various mechanical setups and automation systems. This article explores the significance, functionality, and applications of flexible drag chains, highlighting their role in enhancing operational efficiency in diverse sectors.

A flexible drag chain, also known as cable carrier or energy chain, is designed to guide and protect moving cables, hoses, and other flexible components in machinery. These chains are engineered to withstand repetitive movements and challenging environments while minimizing wear and tear on the cables and hoses they protect. The flexibility of drag chains allows them to curve, bend, and twist as needed, accommodating a range of movement patterns essential for dynamic installations.

One of the key benefits of using flexible drag chains is their ability to streamline operations. In automated production lines, for example, machinery often requires cables and hoses to move along with moving parts. Flexible drag chains help maintain organization by keeping these components contained and tidy, reducing the risk of entanglement or disconnection. This organization not only prolongs the lifespan of the cables but also ensures safer and more reliable operation, significantly reducing downtime caused by maintenance issues.

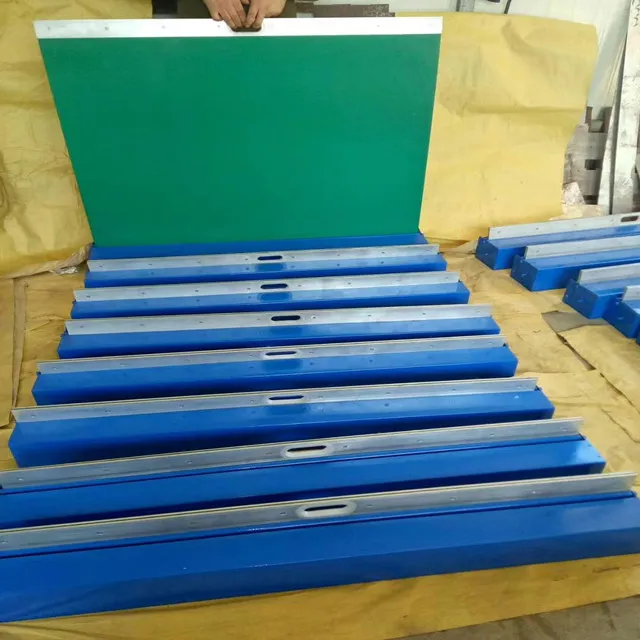

flexible drag chain

Moreover, flexible drag chains are highly customizable. They come in various sizes, materials, and designs to meet the specific needs of different applications. For instance, in industries such as robotics, aerospace, and manufacturing, the ability to tailor drag chains for unique setups enhances overall productivity. Some designs even incorporate features for easy access and quick replacements, further minimizing operational disruptions.

Environmental resistance is another crucial aspect of flexible drag chains. Many come equipped with materials that resist chemicals, extremes in temperature, and other harsh conditions, ensuring they perform reliably even in challenging environments. This durability makes them invaluable in sectors like automotive and textiles, where exposure to diverse elements is common.

In conclusion, flexible drag chains are vital to modern engineering, providing efficient solutions for managing cables and hoses in dynamic systems. Their flexibility, customization options, and durability not only enhance operational efficiency but also contribute to safety and maintenance reduction. As industries continue to evolve and rely more on automation, the significance of flexible drag chains will likely increase, making them an indispensable component in the quest for innovation and efficiency. Embracing this technology can lead to remarkable improvements in productivity and functionality across various fields, paving the way for a more streamlined industrial future.