flexible drag chain

The Versatility of Flexible Drag Chains An In-Depth Look

In the world of mechanical engineering and industrial design, the efficient management of cables and hoses is paramount. Flexible drag chains, also known as energy chains or cable carriers, have revolutionized how we handle these essential components in various applications. Their flexibility, adaptability, and durability make them indispensable in many industries, ranging from manufacturing and robotics to automation and beyond.

Understanding Flexible Drag Chains

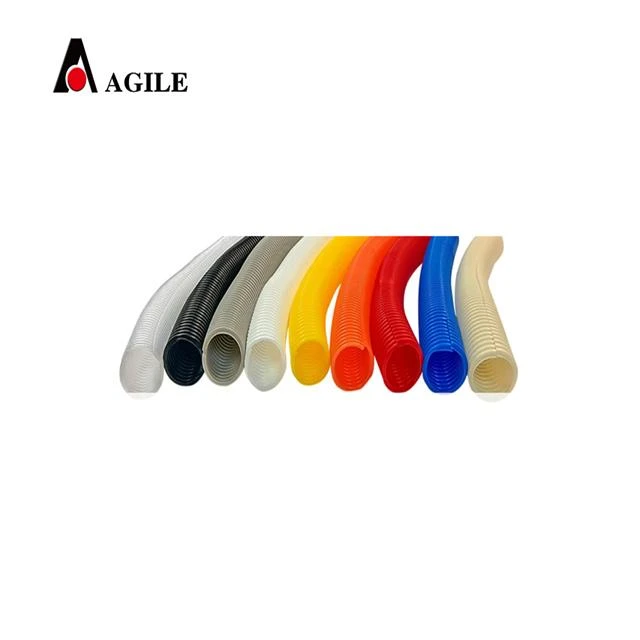

Flexible drag chains are designed to support and guide moving cables and hoses in applications where traditional cable management solutions fall short. They are typically made from robust materials like plastic or steel, which provide both flexibility and strength. The primary function of a drag chain is to protect cables and hoses from wear and tear, as well as to ensure they operate smoothly during movement.

These chains come in a variety of shapes and sizes, accommodating different types of cables and hoses. They can be found in linear applications, such as in conveyor systems, as well as in complex three-dimensional movements, like those seen in robotic arms or CNC machines.

Key Advantages

1. Cable Protection One of the most significant advantages of flexible drag chains is their ability to protect cables from mechanical damage. In environments where equipment moves frequently, cables can undergo intense stress, leading to fraying or breakage. Drag chains encapsulate the cables, shielding them from harsh elements and physical damage.

2. Improved Organization By keeping cables neatly organized, flexible drag chains can enhance workplace efficiency. They prevent tangling and interference, which can cause delays and accidents. An organized system allows for easy identification and replacement of cables, reducing downtime in case of malfunctions.

flexible drag chain

3. Flexibility and Versatility As their name suggests, flexible drag chains can bend and twist, allowing for a high degree of movement and adaptability. This flexibility makes them perfect for dynamic applications where space is limited and movements are varied. Industries such as automotive, aerospace, and manufacturing benefit greatly from the versatility provided by these systems.

4. Customizability Flexible drag chains can be tailored to meet specific needs. Manufacturers offer a range of sizes, shapes, and materials, allowing engineers to design a system that fits their application perfectly. Furthermore, chains can be equipped with various accessories, such as mounting brackets or strain reliefs, to enhance their performance.

5. Durability Made from high-quality materials, flexible drag chains can withstand significant wear and tear, making them suitable for demanding environments. They are often resistant to chemicals, UV radiation, and extreme temperatures, ensuring they can operate reliably in various settings.

Applications Across Industries

Flexible drag chains are utilized across numerous industries, demonstrating their essential role in modern machinery. In manufacturing lines, they manage power and control cables, allowing for smooth operation without interruptions. In robotic applications, they enable precise movement of sensors and power lines, ensuring that robotic arms and components function optimally.

Additionally, in the marine and aerospace industries, drag chains help manage wiring in applications that require exceptional reliability while exposed to harsh environments. Their ability to handle multiple cables and hoses simultaneously makes them a go-to solution for engineers who aim for efficiency and reliability.

Conclusion

In conclusion, flexible drag chains serve as a crucial component in various industrial settings, providing an effective solution for cable management. Their protective features, organizational benefits, customizability, and durability make them invaluable in today’s fast-paced manufacturing and technological landscapes. As machinery continues to evolve and become more complex, the role of flexible drag chains is likely to expand, ensuring that they remain a cornerstone of modern engineering. Whether you are designing a new production line or maintaining equipment in an existing facility, considering the integration of flexible drag chains might be the key to enhancing efficiency and reliability in your operations.