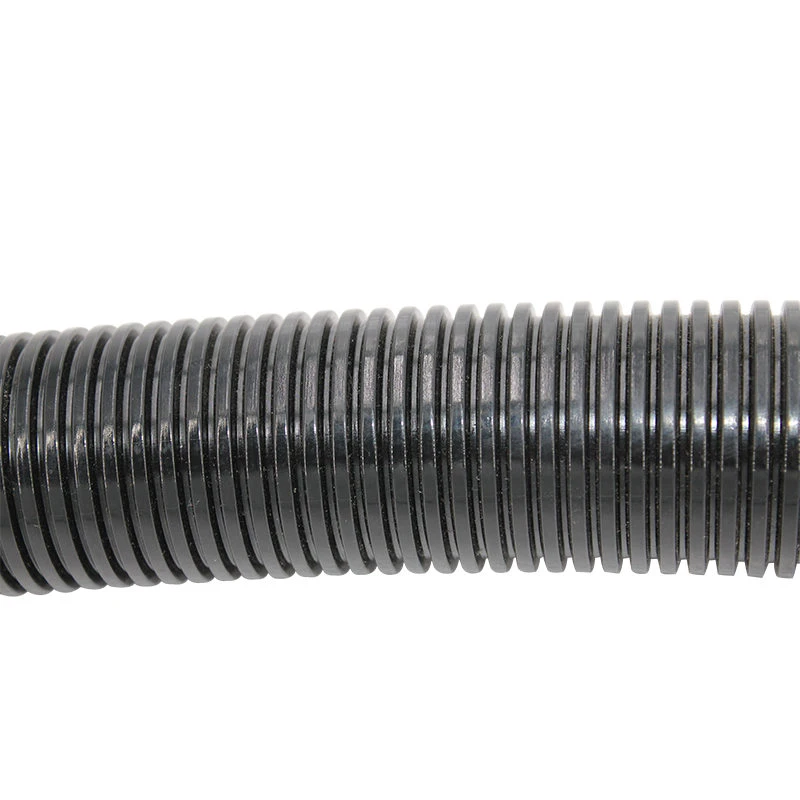

flexible cable track system

The Benefits of Flexible Cable Track Systems in Modern Industries

In today's continuously evolving industrial landscape, the demand for efficient, reliable, and adaptable solutions is paramount. One of the emerging innovations that address these demands is the flexible cable track system. This technology offers a multitude of advantages across various applications, from manufacturing and automation to robotics and transportation.

Understanding Flexible Cable Track Systems

A flexible cable track system, also known as a cable carrier or drag chain, is designed to manage and protect cables and hoses within industrial settings. Unlike traditional rigid solutions, these systems are built with flexibility in mind, allowing for movement in multiple planes while preventing tangling, wear, and damage to the cables they encase. Typically, they consist of a series of interconnected links that create a channel through which cables can pass, providing both support and organization.

Key Advantages

1. Enhanced Mobility and Flexibility One of the primary benefits of flexible cable track systems is their ability to accommodate a wide range of movement. Whether it’s on a machine tool, robotic arm, or automated conveyor, these systems can easily adapt to dynamic environments, making them ideal for applications with high degrees of motion. This flexibility not only improves overall functionality but also enhances production efficiency.

2. Cable Protection In industrial settings, cables often face wear and tear due to constant movement, friction, and environmental factors. Flexible cable track systems are engineered to provide a protective casing, reducing the risk of damage to cables and hoses. This prolongs the operational lifespan of the cables, lowers maintenance costs, and minimizes downtime due to repairs or replacements.

flexible cable track system

3. Organized Cable Management Another significant advantage is the organization they provide. In complex industrial environments, cables can become tangled or misrouted, leading to inefficiencies and safety hazards. Flexible cable track systems help maintain a neat, orderly workspace by containing cables in a designated pathway. This organization not only enhances aesthetics but also improves accessibility for maintenance and upgrades.

4. Increased Safety Safety is a top priority in any industrial application. Flexible cable track systems contribute to a safer working environment by reducing the risk of tripping hazards associated with loose cables. Additionally, with proper cable management, the likelihood of equipment malfunction due to cable interference is significantly reduced, thus protecting both personnel and machinery.

5. Versatile Applications These systems are incredibly versatile and can be used in a variety of industries, including manufacturing, automotive, aerospace, and entertainment. From managing power cables in CNC machines to guiding pneumatic hoses in automated assembly lines, the adaptability of flexible cable track systems caters to numerous applications. Their design allows for customization according to specific needs, ensuring that they can be tailored to any setup.

6. Cost-Effectiveness While the initial investment in a flexible cable track system may be higher than traditional cable management methods, the long-term savings are substantial. These systems reduce cable replacement costs, minimize downtime, and lower maintenance expenses. Furthermore, the increased efficiency and productivity they facilitate can lead to significant gains in profitability.

Conclusion

In summary, flexible cable track systems are revolutionizing how industries manage cables and hoses, providing unparalleled flexibility, protection, and organization. As industries continue to adapt to automation and flexible production environments, the importance of reliable cable management solutions will only grow. Companies looking to improve efficiency, enhance safety, and reduce operational costs would be wise to consider the integration of flexible cable track systems into their operations. As technology advances, these systems will undoubtedly play a crucial role in shaping the future of industrial productivity.