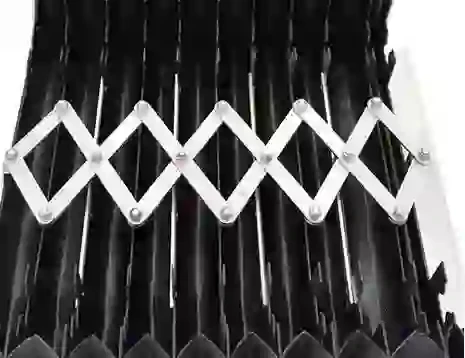

flexible cable carrier chain

Understanding Flexible Cable Carrier Chains Their Importance and Applications

In today's fast-paced industrial landscape, the need for efficient and reliable equipment is more significant than ever. Among various components that facilitate smooth operations, flexible cable carrier chains stand out as a crucial element. These components play a pivotal role in managing cables and hoses in machinery and automated systems, ensuring safety and efficiency. This article will delve into the importance, working principles, and diverse applications of flexible cable carrier chains.

What Are Flexible Cable Carrier Chains?

Flexible cable carrier chains, often referred to as energy chains or drag chains, are specialized components used to organize and protect cables and hoses in dynamic applications. They provide a guiding path for the cables and hoses, allowing them to move freely while preventing wear and tear caused by friction, abrasion, or entanglement. These chains consist of numerous interconnected links that can bend and flex, enabling them to accommodate the relative movements in machinery, such as linear, rotary, or pivoting motions.

Importance of Flexible Cable Carrier Chains

1. Protection of Cables and Hoses One of the primary functions of flexible cable carrier chains is to protect electrical cables, hydraulic hoses, and pneumatic lines from mechanical damage. By enclosing these vulnerable components within a solid structure, the chains significantly reduce the risk of wear and failure, extending the lifespan of the cables and hoses.

2. Improved Organization Cable carrier chains help to organize cables and hoses more effectively, minimizing the chances of tangling or creating unmanageable knots. This not only improves the overall aesthetics of an industrial setup but also facilitates easier troubleshooting and maintenance, as neatly organized cables are easier to identify and access.

3. Safety Enhancement In any industrial environment, safety is paramount. Flexible cable carrier chains reduce the risk of tripping, entanglement, or equipment failure due to loose cables. By securing and guiding cables effectively, these chains contribute to a safer working environment for employees.

4. Space Optimization In many industrial settings, space is at a premium. Flexible cable carrier chains allow for compact design solutions by managing cables in a way that utilizes vertical and horizontal space efficiently. The use of these chains can lead to more streamlined machinery layouts, ultimately saving space and resources.

Working Principles

Flexible cable carrier chains function through a combination of flexibility and rigidity. They consist of a series of links connected in a way that allows them to bend while maintaining structural integrity. As the machines operate and move, the chains flex in response to the movements, allowing the cables and hoses to extend and retract without damaging their insulation or structure.

flexible cable carrier chain

Most flexible cable carrier chains are made from durable materials such as thermoplastics, metals, or a combination of both, providing robust solutions for heavy-duty applications. Additionally, they can be customized to fit specific operational requirements, accommodating various sizes of cables and hoses, as well as differing degrees of motion.

Applications Across Industries

Flexible cable carrier chains find applications in numerous industries, including

- Manufacturing and Automation In automated production lines, where machinery operates with high speeds and repetitive motions, cable carrier chains ensure that cables are correctly guided and protected.

- Robotics Flexible cable carrier chains are essential in robotic systems, where the cables must move in harmony with the joints of the robot without hindering its movement or risking damage.

- CNC Machining In CNC machines, cable carrier chains are used to manage control cables and power lines, ensuring seamless operation and enhanced precision.

- Construction and Material Handling Heavy machinery used in construction sites benefits from cable carrier chains, which protect hydraulic and electrical lines from damage due to constant movement.

- Vehicle Manufacturing In the automotive industry, these chains assist in guiding hoses and wires within assembly lines, contributing to faster production rates and improved quality.

Conclusion

Flexible cable carrier chains are indispensable components in modern industrial settings. Their ability to protect, organize, and streamline cable and hose management makes them a vital choice for various applications across numerous sectors. As industries continue to evolve and push for greater efficiencies, the role of flexible cable carrier chains will undoubtedly grow, ensuring that machinery operates safely and effectively for years to come. Understanding their function and benefits can lead businesses to invest wisely in these solutions, ultimately fostering a more productive environment.