Innovative Solutions for Flexible Cable Carrier Systems in Modern Applications

Understanding Flexible Cable Carriers Essential Components for Modern Machinery

In today's industrial landscape, the seamless operation of machinery is paramount to enhancing productivity and ensuring safety. One critical component that often goes unnoticed in the realm of machinery and automation is the flexible cable carrier, also known as drag chain or energy chain. These essential devices play a vital role in organizing and protecting cables and hoses while allowing for unhindered movement in a dynamic environment.

What is a Flexible Cable Carrier?

A flexible cable carrier is a type of chain-like structure designed to guide and protect flexible cables, hoses, and other energy transmission elements. These carriers are engineered to allow free movement while ensuring that the cables and hoses remain organized, preventing tangling and wear that could lead to costly downtime. Typically constructed from high-strength plastics or metals, flexible cable carriers can endure a variety of conditions, including exposure to chemicals, extreme temperatures, and mechanical wear.

Key Features of Flexible Cable Carriers

1. Flexibility As the name suggests, flexible cable carriers can bend and twist without compromising the integrity of the cables housed within them. This flexibility is crucial in environments where machinery may move in multiple directions.

2. Durability Most carriers are made from robust materials that can withstand harsh conditions. This durability ensures a longer lifespan for both the cables and the carriers, reducing maintenance and replacement costs.

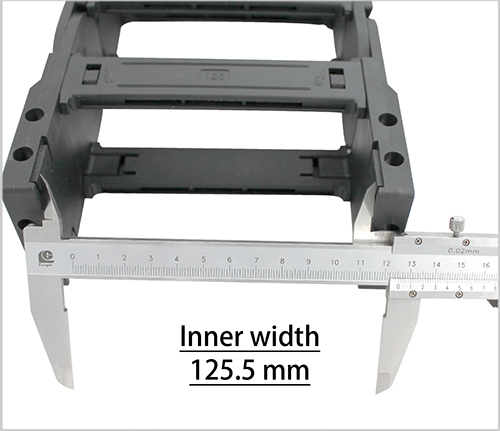

3. Customization Flexible cable carriers can be tailored to meet specific needs. This customization may include varying dimensions, shapes, and materials, ensuring compatibility with diverse machinery types and operational requirements.

4. Ease of Installation These carriers are designed for quick and easy installation, allowing operators to integrate them seamlessly into existing systems. This feature is especially beneficial in facilities where machinery is frequently reconfigured.

flexible cable carrier

5. Protection Flexible cable carriers shield cables and hoses from environmental dangers, such as dust, debris, and mechanical abrasion. This protection is essential in preserving the functionality and integrity of energy systems over time.

Applications of Flexible Cable Carriers

Flexible cable carriers find applications across multiple sectors, including manufacturing, automotive, robotics, and entertainment. In automated assembly lines, they manage power and data cables for robotic arms, ensuring smooth movement and reducing the risk of cable damage. In the automotive industry, these carriers may protect cables that navigate complex machinery or robotic welding arms.

In the entertainment sector, flexible cable carriers are often used in stage equipment, such as lighting rigs, where they manage the extensive array of electrical and data cables that must remain secure while allowing for movement. Similarly, in the aerospace industry, these carriers ensure that essential power and communication lines remain intact within rapidly moving systems.

Advantages of Using Flexible Cable Carriers

Implementing flexible cable carriers into machinery operations can lead to significant advantages. First and foremost, they enhance efficiency by ensuring that cables operate without tangling or interference. This smooth operation can result in increased output and reduced machine stress.

Additionally, cable carriers contribute to safety by minimizing the likelihood of cable-related accidents, such as tripping hazards or equipment malfunction due to damaged wires. Furthermore, using flexible cable carriers can lead to significant cost savings over time due to lower maintenance frequency and extended equipment lifespans.

Conclusion

In conclusion, flexible cable carriers are integral to modern machinery, offering a combination of flexibility, durability, and protection that enhances the functionality and safety of automated systems. With their wide range of applications across various industries, these carriers illustrate the importance of thoughtful design and engineering in facilitating efficient operations. As technology continues to evolve, the role of flexible cable carriers will undoubtedly expand, further solidifying their place as essential components in the machinery of the future. Organizations that recognize and implement these systems will be better poised to tackle the demands of an ever-changing industrial landscape.