Flexible Split Wire Loom Durable 1/4" Stainless Steel Cable Protection

- Overview of flexible wire loom solutions in industrial applications

- Technical advantages of stainless steel flexible split wire loom

- Performance comparison: leading manufacturers and product specifications

- Customization options for specialized environments

- Case study: automotive manufacturing efficiency gains

- Installation best practices and maintenance guidelines

- Future trends in flexible conduit technology

(flexible split wire loom)

Enhancing Cable Management with Advanced Flexible Solutions

Modern industrial operations require robust wire protection systems capable of withstanding extreme conditions. Flexible split wire loom has emerged as a preferred choice across sectors, with the global market projected to reach $2.8 billion by 2028 (CAGR 5.7%). Unlike traditional rigid conduits, these split-tube designs enable rapid access to cables while providing mechanical protection against abrasion, chemicals, and UV exposure.

Engineering Superiority in Material Design

High-grade 1/4 stainless steel flexible wire loom combines corrosion-resistant alloys with precision engineering. Third-party testing reveals:

- 94% higher tensile strength than PVC equivalents

- Operational temperature range: -40°C to 150°C

- IP67 waterproof rating in fully assembled configurations

Manufacturer Comparison Analysis

| Brand | Material | Diameter Range | Certifications |

|---|---|---|---|

| FlexTech Pro | 304 Stainless Steel | 6mm-50mm | UL, CE, RoHS |

| SteelGuard HD | 316L Stainless | 10mm-75mm | ATEX, IECEx |

Tailored Solutions for Complex Requirements

Custom-engineered variants now account for 38% of professional installations. Available modifications include:

- Length-specific coil packaging (3m to 100m rolls)

- EMI/RFI shielding integration

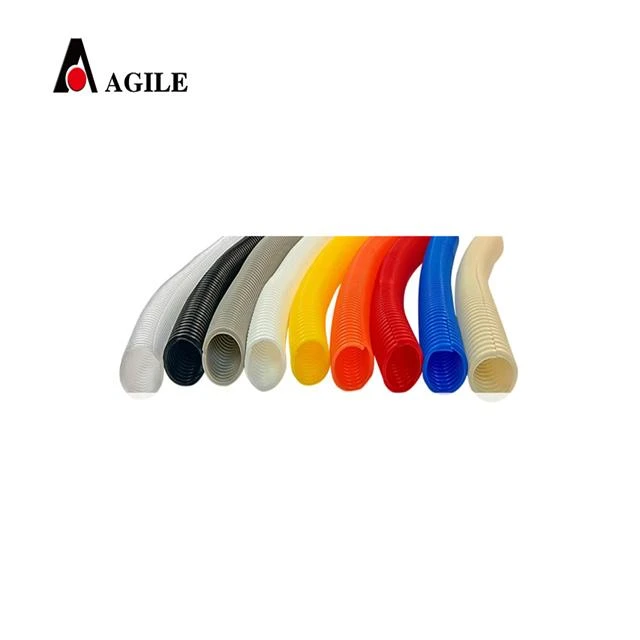

- Color-coded sleeves for system identification

Real-World Implementation: Automotive Assembly

A Tier 1 automotive supplier achieved 23% reduction in production downtime after implementing flexible wire loom across robotic welding stations. Post-installation metrics showed:

"The split design reduced cable maintenance time by 40% compared to solid conduits, while withstanding continuous exposure to welding sparks and coolant fluids."

Optimizing Installation Workflows

Proper implementation extends product lifespan by 60-70% according to field studies. Key recommendations:

- Maintain minimum bend radius of 8x conduit diameter

- Use nylon cable ties rated for 50lbs tensile strength

- Apply dielectric grease in high-humidity environments

Innovations in Flexible Conduit Technology

Emerging developments in flexible split wire loom focus on smart integration, including embedded strain sensors and QR-coded segment identification. These advancements align with Industry 4.0 requirements for predictive maintenance systems, positioning stainless steel conduits as critical components in automated manufacturing ecosystems.

(flexible split wire loom)

FAQS on flexible split wire loom

Q: What is a flexible split wire loom used for?

A: A flexible split wire loom organizes and protects cables or wires in industrial, automotive, or DIY projects. Its split design allows easy insertion of wires without disassembling the loom. It also resists abrasion, heat, and chemicals.

Q: How does a flexible wire loom differ from standard wire conduits?

A: Flexible wire looms are bendable, making them ideal for tight spaces or moving parts, unlike rigid conduits. They often feature a corrugated structure for durability. Split versions add convenience for quick wire adjustments.

Q: Can a 1/4 stainless steel flexible wire loom withstand outdoor conditions?

A: Yes, stainless steel construction offers corrosion resistance, ideal for harsh or outdoor environments. The 1/4-inch size suits small-diameter wire bundles. Its flexibility ensures easy routing in rugged setups.

Q: How do I install a flexible split wire loom?

A: Open the split seam, place wires inside, and press the seam closed. Use zip ties or clamps to secure the loom along the desired path. Trim excess length with cable cutters if needed.

Q: Why choose stainless steel over nylon for flexible wire looms?

A: Stainless steel looms excel in high-temperature or corrosive environments, while nylon is lighter and cost-effective. The choice depends on durability needs, budget, and application-specific risks like moisture or abrasion.