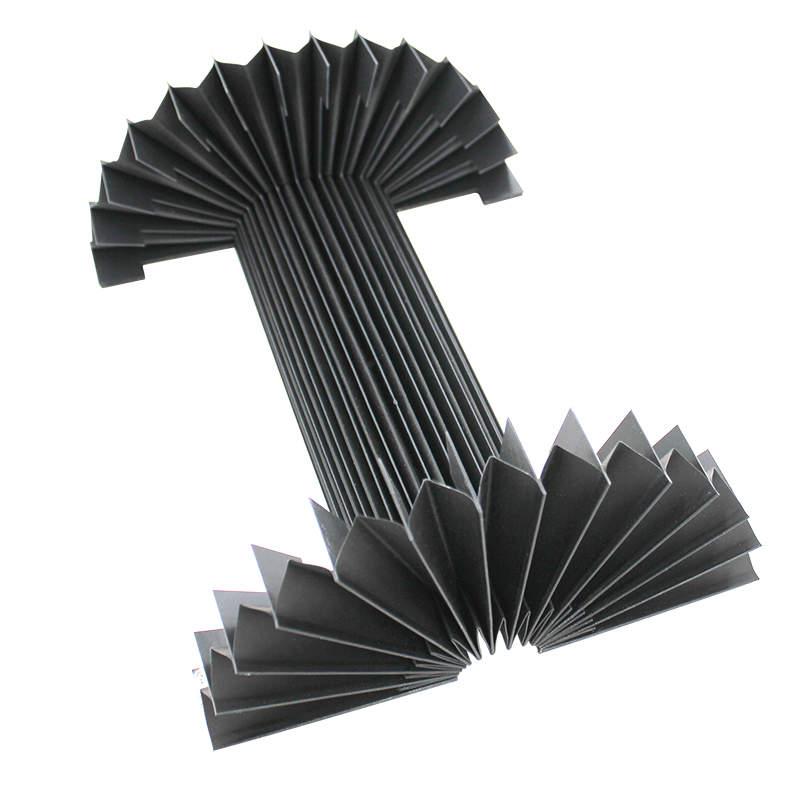

Flexible Sleeve Tubing for Enhanced Performance in Various Industrial Applications and Settings

The Importance of Split Sleeve Tubing in Modern Applications

Split sleeve tubing, a specialized type of tubing system, plays a crucial role in various engineering and manufacturing applications. This innovative design is gaining popularity due to its unique features and the benefits it provides in various industries. From oil and gas to aerospace, split sleeve tubing is integral to enhancing operational efficiency, safety, and versatility.

Understanding Split Sleeve Tubing

Split sleeve tubing consists of a cylindrical sleeve that is intentionally split along its length, allowing it to be easily installed or removed from a particular assembly. The split design offers several advantages over traditional tubing methods. It allows for quick access to the interior of the assembly without disassembling the entire structure, which is particularly useful in maintenance and repair scenarios.

The split sleeve design provides a tight and secure fit when reassembled, ensuring that the integrity of the system remains intact. This feature is crucial in high-pressure applications where leaks can lead to catastrophic failures or safety hazards.

Applications in Various Industries

1. Oil and Gas Industry One of the most prominent uses of split sleeve tubing is in the oil and gas sector. In wellbore applications, split sleeves are used for zonal isolation, helping to prevent fluid movement between reservoir zones. This capability is vital for optimizing production and enhancing well integrity, enabling operators to extract more resources efficiently and safely.

2. Aerospace Engineering In aerospace applications, weight and reliability are critical factors. Split sleeve tubing can be used to connect various components in aircraft and spacecraft structures. Its lightweight nature combined with high strength makes it ideal for aerospace applications where every ounce counts, yet durability is paramount.

split sleeve tubing

3. Automotive Sector In the automotive industry, split sleeves can be found in various components, including fuel and brake systems. They enable quick repairs and replacements while maintaining the system's integrity and performance. Their design is especially advantageous in densely packed environments where access to certain components is challenging.

4. Manufacturing In manufacturing processes, split sleeve tubing offers flexibility when it comes to assembly lines. The ability to quickly disassemble and reassemble parts can significantly reduce downtime during maintenance, ultimately leading to increased productivity.

Advantages of Split Sleeve Tubing

The benefits of split sleeve tubing are manifold. Its design allows for easy installation, maintenance, and removal, making it a cost-effective solution for industries that rely on precision and efficiency. Furthermore, the ability to quickly address issues without the need for extensive downtime is a significant advantage in fast-paced environments.

Additionally, split sleeve tubing enhances safety by providing a secure and leak-resistant connection that can withstand high pressures. This safety feature is critical, particularly in sectors such as oil and gas, where even minor failures can have severe consequences.

Conclusion

In conclusion, split sleeve tubing is an essential component in various industries, facilitating efficient and safe operations. Its unique design allows for quick access and maintenance, making it a preferred choice in oil and gas, aerospace, automotive, and manufacturing applications. As technology advances and industries evolve, the importance of innovative solutions like split sleeve tubing will only grow. By adopting such efficient designs, companies can enhance their operational capabilities, reduce costs, and ensure the safety and reliability of their systems. The future of engineering and manufacturing looks promising with the continued integration of such practical innovations.