Flexible Cable Protection Using Corrugated Conduit for Enhanced Safety and Durability

Understanding Corrugated Cable Conduit Essential Features and Benefits

In our increasingly interconnected world, the importance of effective cable management and protection cannot be overstated. Among the various solutions available, corrugated cable conduit stands out as a favored choice for many industries. This versatile product is designed to safeguard electrical cables and wires, ensuring they remain insulated and protected from environmental factors. Let's delve into the nuances of corrugated cable conduit, exploring its features, benefits, and applications.

What is Corrugated Cable Conduit?

Corrugated cable conduit is a flexible tubing typically made from plastic materials, such as polyethylene or PVC. The distinguishing characteristic of corrugated conduit is its spiral or ribbed outer surface, which provides added strength and flexibility. This unique structure allows the conduit to bend and navigate around obstacles, making it ideal for various installation scenarios.

The flexibility of corrugated conduit is particularly advantageous in environments where cable runs need to change direction, such as in industrial facilities, commercial buildings, and even residential settings. Users can easily manipulate the conduit to fit the specific layout of their projects without compromising the integrity of the cables inside.

Key Features of Corrugated Cable Conduit

1. Durability One of the most significant benefits of corrugated cable conduit is its robust nature. The material used in its construction can resist impact, abrasion, and even harsh chemicals, ensuring that cables remain protected over extended periods.

2. Lightweight Corrugated conduits are generally lightweight compared to traditional metal conduits. This characteristic simplifies installation and reduces the overall load on structures.

3. Water Resistance Many corrugated conduits are designed to be water-resistant, which is crucial for installations in wet or humid environments. This helps prevent moisture from damaging electrical cables, enhancing their longevity.

4. Ease of Installation The flexibility of corrugated conduits makes them easy to install, which can save time and labor costs. They can be cut to size and connected with various fittings, allowing for a streamlined process.

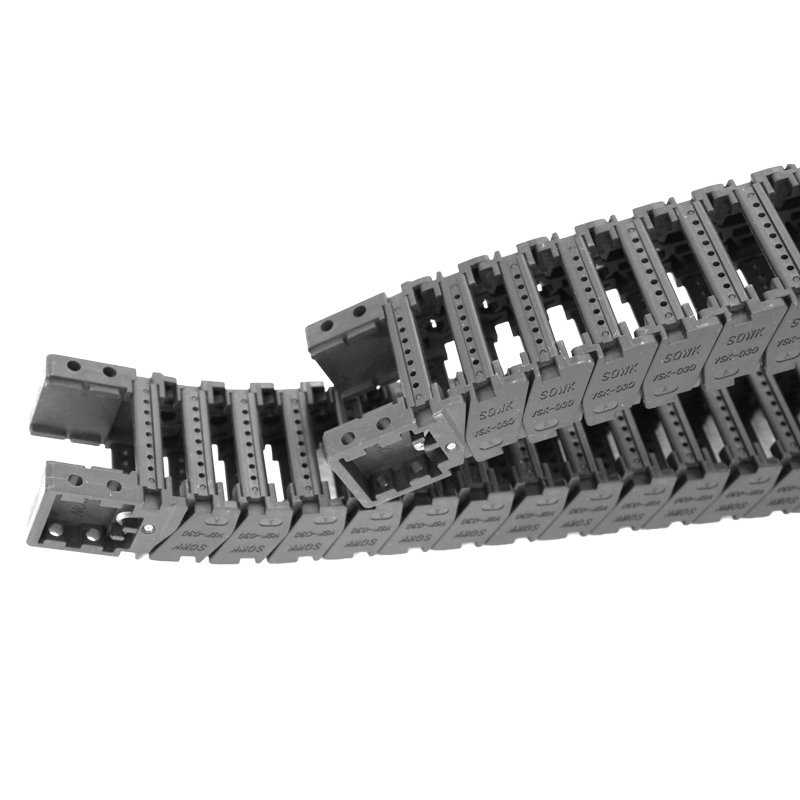

corrugated cable conduit

Applications of Corrugated Cable Conduit

Corrugated cable conduit finds use in a wide range of applications across various sectors

- Industrial Settings In factories and manufacturing plants, electrical systems must be protected from dust, moisture, and mechanical wear. Corrugated conduits safeguard these systems from damage, ensuring safe operation.

- Commercial Buildings In office spaces and commercial establishments, the aesthetic layout of wiring is often a concern. Corrugated conduit allows for organized and concealed cable management, enhancing the overall appearance of the workspace.

- Residential Use Homeowners can also benefit from corrugated cable conduit for wiring their electrical systems. It protects cables from potential hazards while allowing for future upgrades or changes.

- Automotive and Transportation The automotive industry employs corrugated conduits for managing wiring in vehicles, protecting against vibration and environmental stresses.

Conclusion

In summary, corrugated cable conduit presents a flexible, durable, and cost-effective solution for protecting electrical cabling across various applications. Its unique design allows for both adaptability and reliability, making it an essential component in modern wiring systems. As industries continue to evolve and expand, the demand for efficient cable protection solutions like corrugated conduits will only increase, underscoring their significance in the world of electrical management. Whether in industrial, commercial, or residential settings, corrugated cable conduits are undoubtedly a cornerstone of effective cable management.