flex cable track

Understanding Flex Cable Track An Essential Component in Modern Automation

In the realm of modern automation and machinery, flexibility and efficiency are paramount. One vital component that has significantly influenced these aspects is the flex cable track. This innovative solution allows for the organized and efficient routing of cables in dynamic applications, enhancing both performance and longevity of machinery.

Flex cable tracks, also known as cable carriers or drag chains, are designed to guide and protect cables and hoses in various industrial environments. They are particularly beneficial in automated systems where movement is continuous and predictable, such as robotics, CNC machines, and conveyor systems. By providing a structured pathway, these tracks prevent tangling, abrasion, and wear, which can lead to equipment failure and costly downtime.

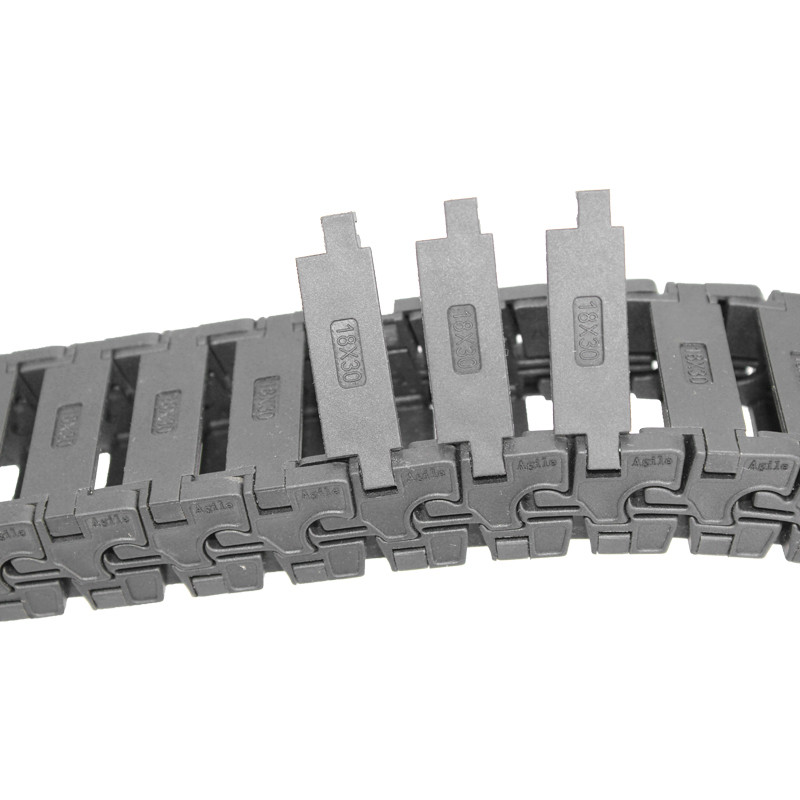

The design of a flex cable track is typically comprised of a series of interconnected links, forming a chain-like structure. This design allows for a wide range of movement while accommodating the bending and flexing of cables. The tracks come in various sizes, materials, and configurations to suit different operational needs, from lightweight plastic options for smaller applications to heavy-duty steel models for extreme conditions.

flex cable track

One of the primary advantages of using flex cable tracks is the reduction of cable wear and tear. In traditional setups, cables are often subject to excessive movement, leading to fraying, cuts, or outright failure. With the implementation of a cable track, the motion is controlled and predictable, which extends the life of the cables and reduces maintenance costs.

Furthermore, flex cable tracks contribute to a cleaner and safer work environment. By organizing and containing cables and hoses, they eliminate tripping hazards, reduce the risk of accidental disconnections, and streamline workflow. This organization also facilitates easier access for maintenance and inspection, enhancing overall operational efficiency.

Another significant benefit is the flexibility in installation and configuration. Flex cable tracks can be tailored to various applications, allowing for customization in length, width, and elevation. This adaptability is crucial for facilities that have unique layouts or are subject to frequent changes in equipment and machinery.

In conclusion, flex cable tracks play a pivotal role in modern automation systems. Their ability to organize, protect, and prolong the life of cables and hoses makes them indispensable in industrial settings. As technology continues to advance and automation becomes more prevalent, the importance of such innovations will only grow, ensuring that operations remain efficient, safe, and reliable. Embracing flex cable tracks not only enhances the current functioning of equipment but also lays a sustainable foundation for future developments in automation.