Exploring the Various Types of Protective Covers and Bellows for Industrial Applications

Understanding Way Covers and Bellows Essential Components in Machinery Protection

In the realm of industrial machinery, precision and protection are paramount. Among the various components engineered for these purposes, way covers and bellows stand out as essential features in safeguarding intricate mechanisms. Their primary role is to protect machine parts from debris, coolant, and chips that may compromise the machine’s performance and longevity. This article delves into the significance, types, and applications of these protective devices.

Significance of Way Covers and Bellows

Way covers and bellows serve a critical function in preserving the integrity of machine tools. By shielding vulnerable components such as slides, guideways, and leadscrews, they prevent wear and tear caused by external contaminants. This protection is vital in environments where machining operations produce significant debris, such as in milling, turning, and grinding processes.

Moreover, these covers help maintain consistent operational precision. When exposed to contaminants, the precision of machine tools can diminish, leading to inaccurate cuts and potential malfunctions. Thus, way covers and bellows are more than just protective elements; they are integral to maintaining the efficacy and reliability of machinery.

Types of Way Covers

Way covers come in various forms, each designed for specific applications and machine configurations

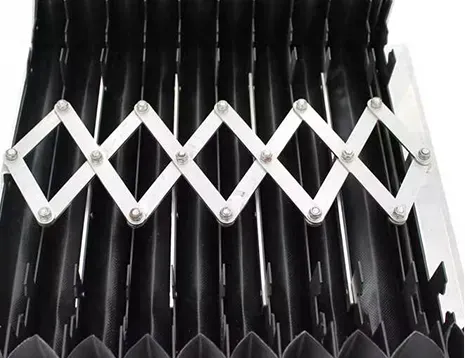

. Some of the most common types include1. Accordion Way Covers These flexible, foldable covers resemble an accordion and can extend and retract according to the machine's movement. Used in vertical and horizontal mills, accordion covers provide excellent protection for motion components.

2. Telescopic Way Covers Telescopic covers consist of multiple overlapping layers that can slide over one another. They are particularly effective for larger machines where a substantial amount of stroke movement occurs, providing enhanced durability and protection.

way covers and bellows

3. Roller-Type Way Covers These are designed with rolling elements that allow for smooth operation while offering protection. They are commonly found in high-speed machining applications where minimal drag is necessary.

Understanding Bellows

Bellows serve a similar protective purpose as way covers but are typically used in applications requiring flexibility and movement in multiple directions. These are often constructed from materials such as rubber, silicone, or fabric, allowing them to expand and contract seamlessly with the machine's operation.

Bellows are versatile components used across various sectors, including automotive, aerospace, and manufacturing. They are particularly beneficial in scenarios where movement occurs in several axes, as they provide comprehensive protection while accommodating the mechanical dynamics.

Applications of Way Covers and Bellows

Way covers and bellows are prevalent in a wide array of industrial applications. They are vital in CNC (Computer Numerical Control) machines, lathes, milling machines, and other automated tools. In addition to machine protection, they play a role in enhancing safety by preventing foreign objects from coming into contact with moving parts.

Furthermore, their use extends to cleanroom environments. In industries such as pharmaceuticals and electronics, where cleanliness is essential, way covers and bellows help maintain the required sterile conditions by containing dust and debris.

Conclusion

In conclusion, way covers and bellows are indispensable components in the realm of industrial machinery, providing essential protection and enhancing operational efficiency. By safeguarding critical machine parts against contaminants, they play a pivotal role in ensuring accuracy, longevity, and reliability. As industries continue to evolve and adopt advanced technologies, the importance of these protective devices will undoubtedly grow, underscoring their significance in modern manufacturing and engineering applications.