Exploring the Benefits and Applications of Machine Way Covers and Bellows in Manufacturing Environments

The Role of Machine Way Cover Bellows in Industrial Applications

In the world of industrial manufacturing, precision and reliability are paramount. One component that significantly contributes to these aspects is the machine way cover bellows. These protective devices have become integral in safeguarding machinery, ensuring operational longevity, and maintaining high standards of performance. This article delves into the importance of machine way cover bellows, their applications, and the benefits they provide to various industries.

Understanding Machine Way Cover Bellows

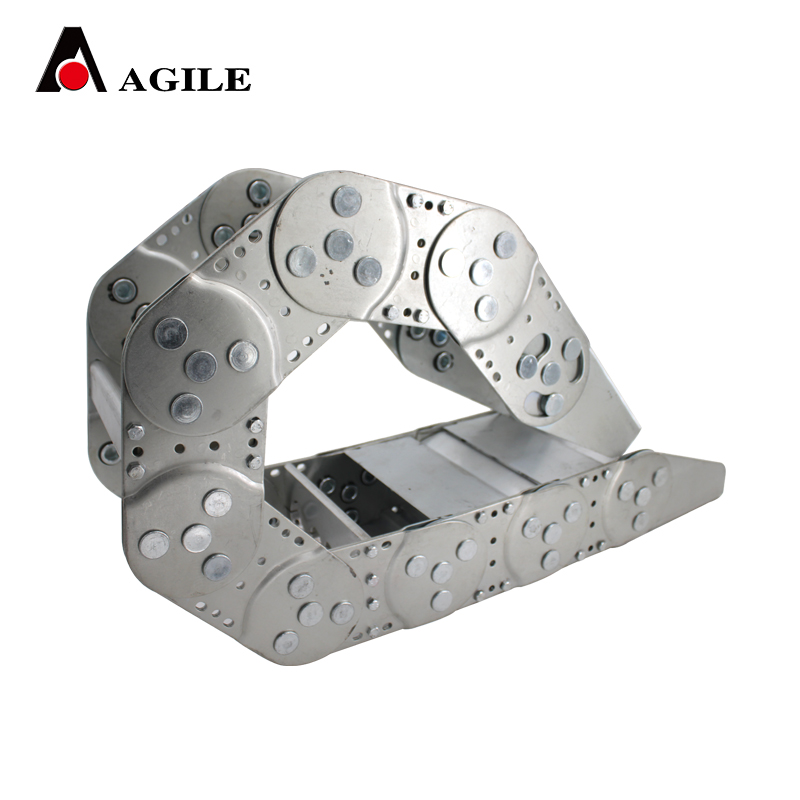

Machine way cover bellows, often simply called bellows or way covers, are flexible protective covers mounted on machines to shield critical components from debris, coolant, and other contaminants. They are typically made from materials such as rubber, polyurethane, or metal, chosen for their durability and flexibility. The design allows the bellows to expand and contract, accommodating the movement of machine parts, particularly in CNC (Computer Numerical Control) machines, lathes, and milling machines.

Protection from Contaminants

One of the primary functions of machine way cover bellows is to protect the machine's internal components. In manufacturing environments, metal shavings, dust, and coolant are common byproducts of machining operations. Without adequate protection, these contaminants can impede the movement of machine parts, leading to wear and tear, inaccuracies, and potential breakdowns. The bellows act as a barrier, preventing particles from entering critical areas such as the guideways and ball screws.

Enhancing Precision and Performance

machine way cover bellows

Precision is crucial in manufacturing, especially in industries like aerospace, automotive, and electronics

. The presence of contaminants can result in dimensional inaccuracies and affect the overall performance of the machinery. By using machine way cover bellows, manufacturers can ensure that their machines operate smoothly and precisely. The bellows help maintain a clean working environment, allowing for better machining results and improved product quality.Longevity of Machinery

Investing in machine way cover bellows can significantly extend the life of industrial equipment. By preventing damage from foreign particles and reducing the frequency of maintenance, these protective covers contribute to a more sustainable operational model. Machines equipped with effective way covers tend to require fewer repairs and exhibit less downtime, ultimately resulting in cost savings for manufacturing facilities.

Customization and Versatility

Another advantage of machine way cover bellows is their adaptability to different types of machinery and operating conditions. Manufacturers can customize bellows to fit specific machines, considering factors such as stroke length, speed, and environmental conditions. This versatility means that across various applications—whether it be in CNC machining, robotics, or fabrication—way covers can be designed to meet the unique needs of each scenario.

Conclusion

In conclusion, machine way cover bellows play a critical role in the manufacturing sector by providing essential protection for machinery, enhancing precision, and contributing to the longevity of equipment. Their ability to safeguard internal components from contaminants while allowing for dynamic movement makes them invaluable in maintaining operational efficiency. As industries continue to advance technologically, the importance of robust protective measures like machine way cover bellows cannot be overstated. Investing in high-quality bellows not only boosts productivity but also fosters a commitment to quality and reliability in manufacturing processes. Ultimately, the strategic implementation of machine way cover bellows represents a proactive approach to industrial success, safeguarding both machinery and the overall integrity of the manufacturing workflow.