Exploring the Benefits and Applications of 1% 2% Split Loom for Cable Management Solutions

Understanding 1% 2% Split Loom A Comprehensive Guide

In the realm of engineering, manufacturing, and DIY projects, split loom tubing often emerges as an essential component for cable management and protection. While there are various sizes and types of split loom, the 1% 2% split loom has gained particular attention for its unique characteristics and applications. In this article, we will explore what 1% 2% split loom is, its benefits, uses, and installation methods.

What is 1% 2% Split Loom?

Split loom tubing is a flexible conduit that protects and organizes wires and cables. It is typically made from a combination of materials, including polyethylene, which offers durability and resistance to wear. The designation “1% 2%” refers to the specific dimensions or diameter ratios in the context of the split loom application. Generally, this implies a profile where the tubing is divided to facilitate easy insertion and removal of cables while maintaining an appropriate level of protection.

This split design is crucial when working with multiple wires, as it allows for the streamlined routing of electrical systems, preventing tangled wires and potential hazards. The loom acts as a safeguard against external factors such as moisture, abrasions, and chemicals that could damage the wires over time.

Benefits of Using 1% 2% Split Loom

1. Protection The primary function of split loom tubing is to coat and shield cables from physical damage. By creating a barrier against sharp edges, fraying, and moisture, split loom enhances the longevity of the wiring system.

2. Organization Split loom helps bundle multiple cables together, making it easier to track and identify individual wires. This organization is not only aesthetically pleasing but also simplifies maintenance and troubleshooting.

3. Flexibility The flexible nature of split loom allows it to bend and twist without cracking. This flexibility makes it ideal for applications in tight spaces or where movement is expected, such as in vehicles or machinery.

1 2 split loom

4. Ease of Installation Installing 1% 2% split loom is relatively straightforward. The split design means that installers can quickly add or remove cables as needed without the hassle of threading each wire through a solid tube.

Common Applications

1. Automotive Industry Split loom is frequently used in vehicles to protect wiring harnesses from heat, moisture, and mechanical damage. It ensures that the electrical system remains intact despite the rigorous conditions involved in driving.

2. Home Automation With the rise of smart homes, split loom serves a vital role in managing the various electrical cables associated with lighting systems, sensors, and smart devices.

3. Industrial Equipment Machinery often contains numerous electrical cables running throughout. Split loom helps keep these wires organized and protected in industrial settings, which may expose them to harsh environmental conditions.

4. DIY and Home Projects Hobbyists and home improvement enthusiasts frequently use split loom for custom electrical projects, ensuring that their installations are both functional and tidy.

Installation Tips

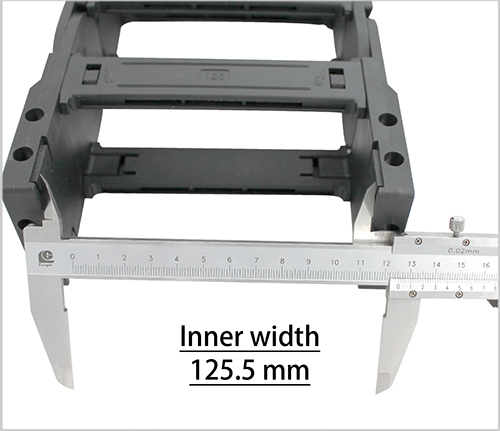

When installing 1% 2% split loom, it's essential to choose the right size for your cables. The diameter should provide a snug fit without being overly tight. Measure the outer diameter of the bundled cables and select split loom that accommodates this measurement. It’s also advisable to cut the tubing to the desired lengths with sharp scissors or a utility knife for a clean edge.

In conclusion, the 1% 2% split loom is a valuable tool for anyone working with electrical systems. Understanding its properties, benefits, and installation methods can significantly enhance the quality and safety of your projects. Whether in automotive, industrial, or home settings, this simple yet effective solution helps uphold the integrity of wires and cables, fostering efficient and neat electrical management.