Exploring the Advantages and Applications of Synchronous V Belts in Modern Mechanical Systems

Understanding Synchronous V Belts Features, Benefits, and Applications

Synchronous v belts, known for their unique design and functionality, play a critical role in various mechanical systems. Unlike traditional V-belts, which rely on friction between the belt and pulleys for power transmission, synchronous belts use precise tooth engagement to ensure accurate motion transfer. This article delves into the essential features, benefits, and applications of synchronous v belts.

Features of Synchronous V Belts

Synchronous v belts are characterized by their toothed structure, which meshes with matching grooves on the pulleys. This design allows for synchronous motion, enabling the belt and pulleys to rotate in a consistent and predictable manner. The primary features of synchronous v belts include

1. Toothed Design The teeth on the belt ensure a tight fit with the pulley grooves, minimizing slippage and providing a positive drive. 2. Material Composition Typically made from a combination of rubber and reinforcing materials, these belts are designed for durability and resistance to wear and tear. 3. Variety of Sizes Synchronous v belts come in various sizes and configurations, making them suitable for different machinery and applications. 4. Temperature Resistance Many synchronous belts are engineered to withstand significant temperature variations, ensuring reliable performance in diverse environments.

Benefits of Synchronous V Belts

The use of synchronous v belts offers several advantages over traditional belts, making them a preferred choice in various industries

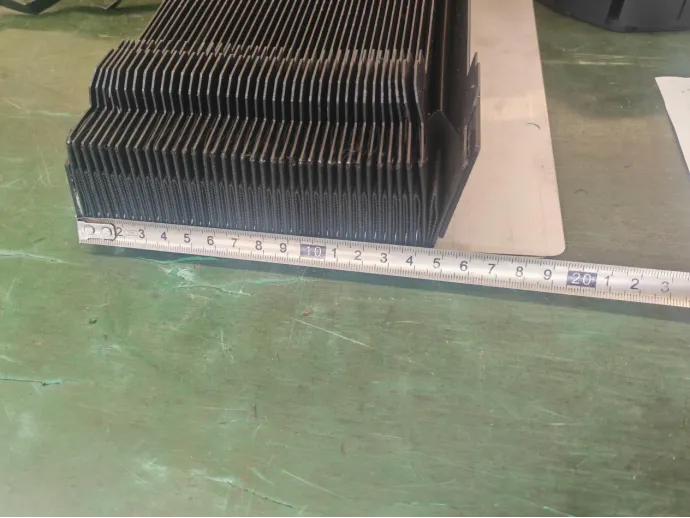

synchronous v belt

1. Precision The tooth-to-groove engagement allows for precise synchronization between driving and driven components, which is crucial in applications requiring exact timing. 2. Reduced Slippage Synchronous v belts experience minimal slippage, which translates into more efficient power transmission and less energy loss. 3. Longer Lifespan With their robust design and materials, these belts tend to have a longer lifespan compared to conventional belts, reducing the frequency of replacements and maintenance costs. 4. Lower Noise Levels The smooth interaction of teeth and pulleys leads to quieter operation, an essential factor in environments where noise reduction is necessary. 5. Improved Load Capacity Synchronous v belts can handle heavier loads due to their efficient design, making them suitable for heavy-duty applications.

Applications of Synchronous V Belts

Synchronous v belts are widely used across various industries due to their versatility and performance characteristics. Some notable applications include

1. Automotive Industry Synchronous belts are commonly used in engines for timing applications, ensuring that camshaft and crankshaft rotations remain synchronized. 2. Industrial Machinery In manufacturing settings, these belts drive conveyors, packaging machinery, and textile machines, where precise timing and reliable operation are essential. 3. Robotics In robotic systems, synchronous v belts play a crucial role in ensuring precise control of movement and positioning, critical for automation technologies. 4. HVAC Systems Synchronous belts are employed in heating, ventilation, and air conditioning systems, where efficient operation and reliability are paramount. 5. Elevators and Escalators The precision and strength of synchronous v belts make them ideal for applications in elevators and escalators, providing smooth and reliable vertical transport.

Conclusion

Synchronous v belts represent a significant advancement in the field of power transmission, offering improved precision, efficiency, and longevity compared to traditional options. Their unique features and numerous benefits make them indispensable in various applications, from automotive engines to industrial machinery and beyond. As technology continues to evolve, the role of synchronous v belts will likely become even more prominent in ensuring optimal performance across diverse mechanical systems.