Ensuring Operator Safety with Protective Bellow Covers: An In-Depth Analysis

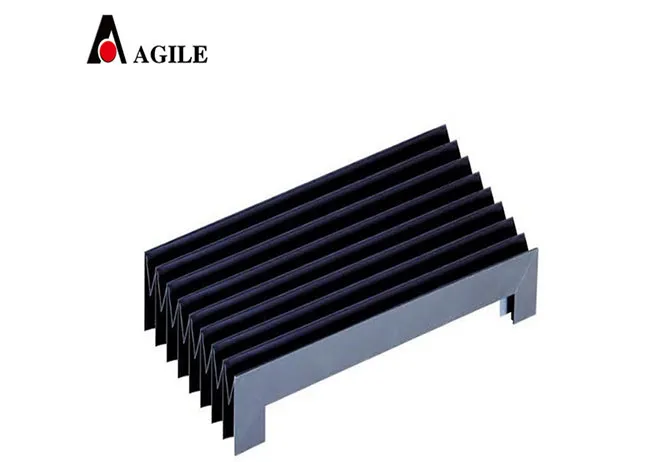

Protective bellow covers play a crucial role in maintaining the safety of machinery operators. By safeguarding sensitive components and reducing exposure to hazards, these covers help to prevent accidents and injuries. This guide analyzes how different types of bellow covers, including rubber bellow covers and CNC machine bellow covers, contribute to machine safety and operator protection.

Role of Protective Bellow Covers in Operator Safety

Protective bellow covers are designed to shield machinery components from contaminants and mechanical damage, contributing significantly to the safety of operators. Here's how they enhance safety:

Shielding Moving Parts: Protective bellow covers guard moving parts of machinery, such as guide rails and spindles, from debris and external impacts. By covering these components, they reduce the risk of accidental contact and injuries.

Preventing Accidents: By concealing sharp edges and rotating parts, rubber bellow covers and other types of covers help to prevent accidents caused by inadvertent contact with machinery parts. This reduces the likelihood of cuts, bruises, or more severe injuries.

Reducing Exposure to Harmful Substances: CNC machine bellow covers protect against exposure to harmful substances like coolant, oil, and dust. They prevent these substances from coming into contact with operators and causing health issues.

Benefits of Rubber Bellow Covers for Safety

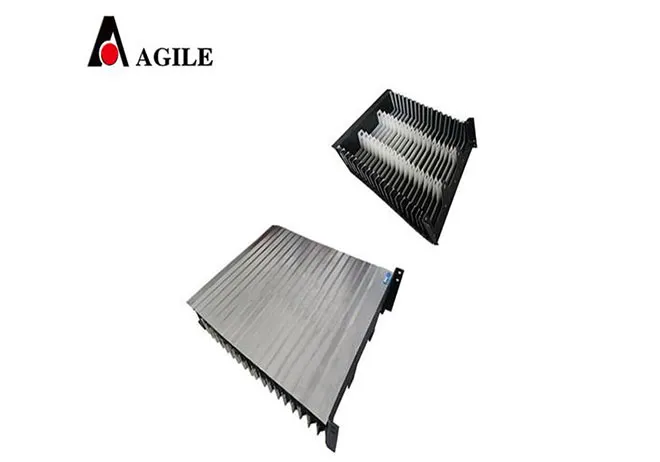

Rubber bellow covers are specifically designed to offer durability and flexibility, making them ideal for various industrial applications. Here’s how they contribute to safety:

Durability: Rubber bellow covers are highly resistant to abrasion, chemicals, and extreme temperatures. This durability ensures long-lasting protection for both the machinery and the operator.

Flexibility: The flexible nature of rubber allows these covers to conform to different shapes and sizes, providing comprehensive protection for moving parts while accommodating their movement.

Impact Resistance: Rubber bellows can absorb and dissipate impact forces, reducing the risk of damage to machinery and minimizing the potential for operator injuries.

CNC Machine Bellow Covers and Their Safety Advantages

CNC machine bellow covers are designed for use with CNC machines, which have intricate and high-speed moving parts. Their safety advantages include:

Precision Protection: CNC machines often operate with high precision and speed. CNC machine bellow covers ensure that sensitive components remain protected, preventing accidental exposure to sharp or rotating parts.

Dust and Debris Containment: These covers prevent dust and debris from contaminating the machine and the operator’s workspace. This containment helps to maintain a clean and safe working environment.

Enhanced Operator Visibility: By protecting internal components, these covers reduce the need for frequent maintenance and inspections, allowing operators to focus on their tasks without distractions.

Analyzing Machine Safety with Protective Bellow Covers

To ensure comprehensive safety, it’s essential to evaluate how protective bellow covers impact overall machine safety. Consider the following aspects:

Design and Fit: Proper design and fit of the covers are crucial for effective protection. The covers should be tailored to the specific machinery to cover all critical components and moving parts.

Maintenance and Inspection: Regular maintenance and inspection of the bellow covers are necessary to ensure they remain effective. Check for signs of wear, damage, or contamination, and replace or repair as needed.

Operator Training: Operators should be trained on the importance of bellow covers and how to recognize when they need attention. Proper training helps to ensure that operators understand how to maintain a safe working environment.

Compliance with Safety Standards: Ensure that the bellow covers meet relevant safety standards and regulations. Compliance with these standards helps to ensure that the covers provide adequate protection and contribute to overall safety.

Enhancing Safety with Protective Bellow Covers

Protective bellow covers, including rubber bellow covers and CNC machine bellow covers, are vital for ensuring the safety of machinery operators. By protecting moving parts, reducing exposure to harmful substances, and preventing accidents, these covers play a crucial role in maintaining a safe working environment. To maximize safety, choose the right type of cover for your machinery, ensure proper installation and maintenance, and provide adequate training for operators. This comprehensive approach will help to enhance safety and protect both the machinery and its operators.