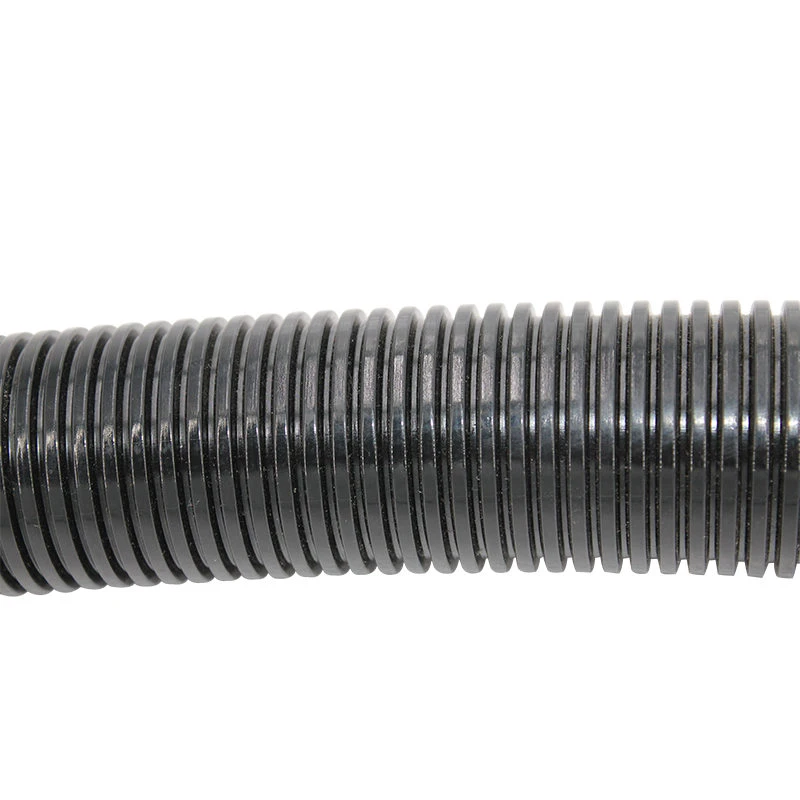

15*40 MT series bridge type high strength plastic nylon energy chain

In the world of modern manufacturing and automation, energy chain cable carriers have emerged as indispensable components, silently underpinning many of the high-tech systems that define today's industrial landscape. These innovative carriers are designed to protect, guide, and manage cables and hoses in dynamic environments, enabling seamless operation in applications ranging from robotics to automated machinery. Their design and functionality offer significant advantages in terms of efficiency, safety, and longevity, and their importance cannot be overstated in industries demanding precision engineering.

The authority of energy chain cable carriers in industrial automation is reinforced by documented case studies, demonstrating their impact across various sectors. For example, a leading automotive manufacturer integrated advanced energy chains in their assembly lines, achieving a marked increase in machine uptime and a reduction in cable-related maintenance costs. This helped the company to maintain its competitive edge by enhancing production efficiency. Equally vital is the trustworthiness these systems offer, as they are critical for safety in environments where malfunctioning components could lead to significant hazards. Ensuring cables remain secure and intact prevents accidents and supports compliance with industry regulations. This reliability also extends to energy chain carriers' environmental credentials, as many versions are now available in recyclable materials, aligning with the burgeoning demand for sustainable manufacturing processes. User experiences further validate the importance of these cable management solutions. Technicians and engineers frequently cite the ease of use and longevity of energy chain cable carriers as major benefits, noting the simplification of complex cabling systems and the resulting reduction in time and resources spent on maintenance. In conclusion, the role of energy chain cable carriers in enhancing operational efficiency and safety within industrial settings is pivotal. Their sophistication and versatility signify them as a cornerstone in cable management solutions. As industries relentlessly pursue automation and efficiency, the demand for reliable, high-performance energy chain cable carriers will undoubtedly grow, cementing their status as essential components in the quest for optimizing industrial productivity.

The authority of energy chain cable carriers in industrial automation is reinforced by documented case studies, demonstrating their impact across various sectors. For example, a leading automotive manufacturer integrated advanced energy chains in their assembly lines, achieving a marked increase in machine uptime and a reduction in cable-related maintenance costs. This helped the company to maintain its competitive edge by enhancing production efficiency. Equally vital is the trustworthiness these systems offer, as they are critical for safety in environments where malfunctioning components could lead to significant hazards. Ensuring cables remain secure and intact prevents accidents and supports compliance with industry regulations. This reliability also extends to energy chain carriers' environmental credentials, as many versions are now available in recyclable materials, aligning with the burgeoning demand for sustainable manufacturing processes. User experiences further validate the importance of these cable management solutions. Technicians and engineers frequently cite the ease of use and longevity of energy chain cable carriers as major benefits, noting the simplification of complex cabling systems and the resulting reduction in time and resources spent on maintenance. In conclusion, the role of energy chain cable carriers in enhancing operational efficiency and safety within industrial settings is pivotal. Their sophistication and versatility signify them as a cornerstone in cable management solutions. As industries relentlessly pursue automation and efficiency, the demand for reliable, high-performance energy chain cable carriers will undoubtedly grow, cementing their status as essential components in the quest for optimizing industrial productivity.