Innovative Solutions for Energy Chain Cables in Modern Industrial Applications

Understanding Energy Chain Cables The Backbone of Motion Technology

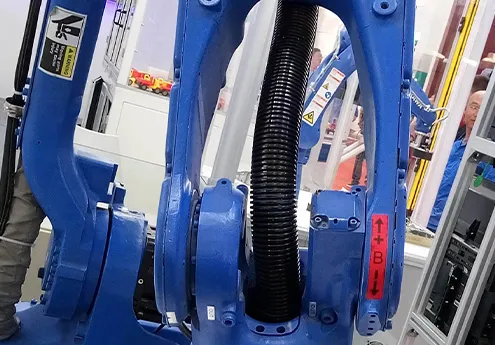

In the rapidly advancing world of automation and robotics, the importance of reliable and efficient power supply systems cannot be overstated. One of the pivotal components in this domain is the energy chain cable, also known as a drag chain or cable carrier. These innovative structures are designed to organize, protect, and guide cables and hoses in various industrial applications, ensuring the uninterrupted flow of energy to machinery and systems in motion.

What is an Energy Chain Cable?

An energy chain cable is essentially a flexible conduit that houses and organizes cables and hoses used for power, data transmission, and fluid transfer. Acting like a protective sleeve, energy chains are engineered to manage the dynamic and repetitive motions of machinery in applications such as CNC machines, robotic arms, and automated production lines. They are crucial in environments where failure of a cable can result in costly downtime, safety risks, and equipment damage.

The Key Benefits of Energy Chain Cables

1. Protection Against Wear and Tear Energy chain cables are designed to shield cables and hoses from abrasion, crushing, and environmental factors. The chains reduce friction between moving parts, significantly extending the lifespan of the contained cables.

2. Organization and Space Efficiency These chains help to prevent tangling and cluttering of wires and hoses. By neatly organizing multiple cables, energy chain systems improve the aesthetics of workspaces and enhance safety by reducing the risk of tripping hazards.

3. Flexibility and Customization Modern energy chain cables come in various sizes, materials, and configurations, making them adaptable to a wide range of settings and requirements. They can be tailored for specific applications, including extreme temperatures, high speeds, and unique spatial constraints.

4. Easy Installation and Maintenance Installing energy chains is typically straightforward, allowing for quick setup. Additionally, many systems are designed for easy access, which simplifies maintenance, reduces downtime, and helps keep operating costs low.

5. Enhanced Performance With engineered designs that minimize resistance and drag, energy chain cables contribute to smoother operations and improved performance of machines. By ensuring reliable connections and reducing wear, they facilitate the efficiency of automated systems.

Applications of Energy Chain Cables

energy chain cable

Energy chain cables find their use in various industries. In the manufacturing sector, they are integral to conveyor systems, assembly lines, and robotic applications. In the automotive industry, they support automated guided vehicles (AGVs) and robotic arms. Other applications include packaging machines, printing presses, and even in medical equipment where precise, reliable operation is paramount.

In the entertainment industry, energy chain cables are utilized in stage rigging and lighting systems, providing flexibility and reliability for complex setups. Additionally, they are becoming increasingly popular in the renewable energy sector, particularly in wind turbines, where they help manage the electrical components that control blade movements.

Choosing the Right Energy Chain Cable

When selecting an energy chain cable, several factors must be considered to ensure optimal functionality

- Cable Type and Size It is essential to match the energy chain with the cables it will carry. Factors such as diameter, flexibility, and the number of conductors need to be taken into account.

- Operating Environment Consideration of temperature extremes, potential exposure to chemicals, and environmental conditions is crucial to ensuring the longevity and reliability of the cables.

- Motion Dynamics The type of motion—linear, rotary, or helical—will influence the design and configuration of the energy chain.

- Application Requirements Each application may have specific needs, such as speed, length of travel, or payload, that will affect the selection of the energy chain.

Conclusion

The energy chain cable is an indispensable component in the field of automation and industrial technology. As industries continue to embrace automation and robotics, the demand for robust, reliable, and efficient energy supply systems will only grow. Understanding the functionality and benefits of energy chain cables is key for engineers and business owners looking to optimize their operations and maintain a competitive edge in the modern industrial landscape.