Optimizing Performance with Energy Chain Cables for Efficient Power Transmission Solutions

Understanding Energy Chain Cables An Essential Component in Modern Automation

In today's rapidly evolving industrial landscape, the pursuit of efficient and reliable energy transfer systems has never been more critical. One of the unsung heroes of modern automation technology is the energy chain cable, a vital component that facilitates the movement of energy and data in dynamic applications. This article will explore what energy chain cables are, their applications, advantages, and considerations for selection.

What Are Energy Chain Cables?

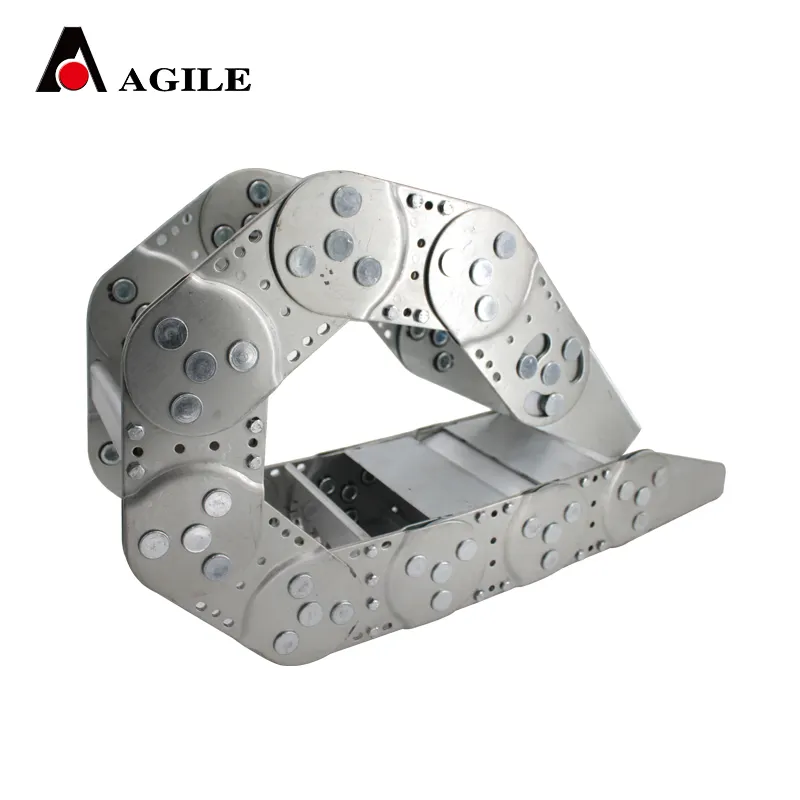

Energy chain cables, often referred to as drag chain cables or flex cables, are specially designed wires that are used in conjunction with energy chains. An energy chain, or cable carrier, is a conduit system that protects and guides cables in applications where relative motion is involved, such as robotic arms, machinery, and conveyor systems. Energy chain cables are engineered to endure repetitive bending and flexing while maintaining their functionality and integrity over time.

These cables are constructed with durable materials and specialized designs that enable them to withstand harsh operational environments, including extreme temperatures, chemicals, and mechanical wear. The cables typically consist of a core of conductive materials surrounded by insulation, and they are equipped with multiple conductors or fibers to facilitate both power and data transmission.

Applications of Energy Chain Cables

The versatility of energy chain cables means they can be found in a wide range of industries and applications. In manufacturing, they play a crucial role in automated machinery, enabling power and signal transmission between stationary and moving parts. Industries such as automotive manufacturing, aerospace, and machine tool production heavily rely on these cables for their robotic systems, CNC machines, and assembly lines.

In entertainment, energy chain cables are used in stage lighting and sound systems, where flexibility and reliability are paramount. They are also integral to the operation of wind turbines, cranes, and other heavy machinery where movement occurs, ensuring that power and data flow seamlessly.

Advantages of Energy Chain Cables

1. Durability One of the most significant benefits of energy chain cables is their robustness. They are specifically designed to withstand the rigors of continuous movement, reducing the likelihood of wear and tear compared to standard cables.

2. Flexibility Energy chain cables offer excellent flexibility, allowing them to bend and twist without damaging the internal conductors. This adaptability is crucial in applications where space is limited or where motion is complex.

3. Reduced Downtime By utilizing energy chain cables, industries can minimize unexpected breakdowns due to cable failure. This leads to reduced downtime, enhancing productivity and operational efficiency.

energy chain cable

4. Organized Cable Management Energy chains provide a systematic way to route cables in industrial settings, reducing clutter and simplifying maintenance and troubleshooting.

5. Customization Manufacturers offer a variety of energy chain cables tailored to specific applications, allowing users to select the best-fit solutions for their unique needs.

Selecting the Right Energy Chain Cable

When choosing energy chain cables, several factors must be considered to ensure optimal performance

1. Bending Radius Always check the minimum bending radius specified by the manufacturer. The cable should be able to flex without exceeding this limit during operation.

2. Cable Length Determine the length required for your application, factoring in the movement range of the equipment.

3. Environmental Factors Consider the operational environment, including temperature, humidity, and exposure to chemicals. Specific cables are designed to withstand harsh conditions.

4. Conductors and Insulation Choose the right type of conductor materials (copper or aluminum) and insulation materials (PVC, TPE, etc.) based on electrical needs and environmental resistances.

5. Application-Specific Features If your application requires data connections, opt for cables with fiber optics or shielded conductors to ensure signal integrity.

Conclusion

Energy chain cables are a critical component of modern automated systems, providing reliable energy and data transmission in dynamic environments. With their durability, flexibility, and a range of applications, they play an indispensable role in enhancing efficiency and productivity across various industries. By understanding their advantages and selecting the appropriate cables tailored to specific needs, businesses can ensure continuous operations while minimizing downtime. As technology advances, the significance of energy chain cables will only continue to grow, underscoring their importance in the future of automation.