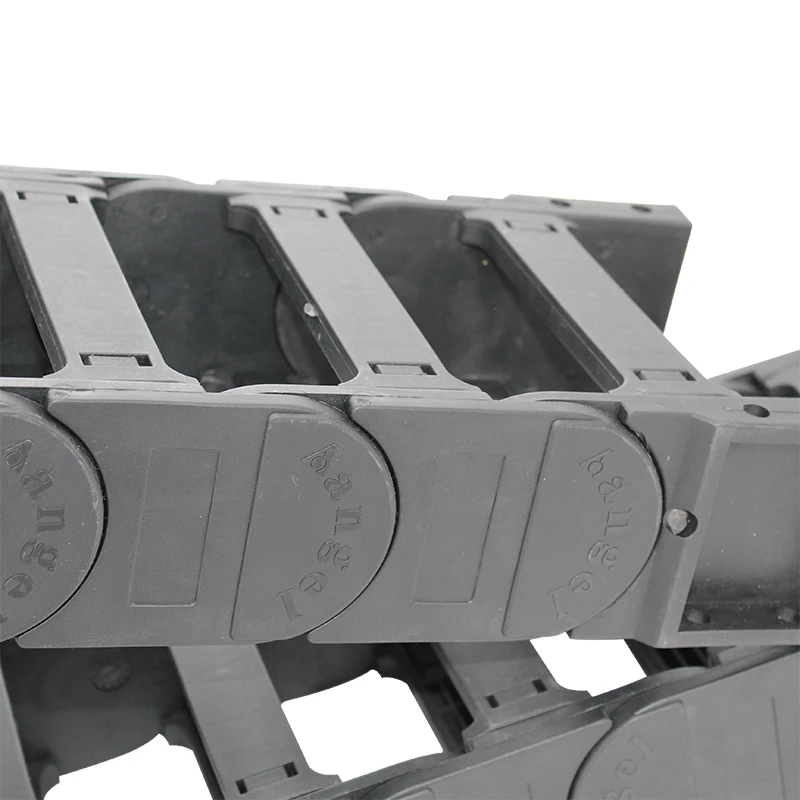

enclosed cable carrier

The Essential Role of Enclosed Cable Carriers in Modern Machinery

In the world of industrial machinery and automation, managing and organizing cables and hoses is crucial to ensuring efficient operation and safety. One of the most effective solutions to this problem is the use of enclosed cable carriers. These devices, also known as cable tracks or drag chains, serve as protective conduits for electrical cables and fluid hoses in various applications. This article delves into the features, advantages, and applications of enclosed cable carriers.

What Are Enclosed Cable Carriers?

Enclosed cable carriers consist of interconnected links or segments that form a flexible and durable structure, allowing for the organized movement of cables and hoses. The enclosed design protects the internal lines from mechanical wear, ambient environmental factors, and accidental damage. These carriers are typically made from robust materials like plastic, steel, or aluminum, providing them with strength and resilience against harsh operating conditions.

Benefits of Using Enclosed Cable Carriers

1. Protection One of the primary advantages of enclosed cable carriers is their ability to safeguard delicate wiring and hoses from abrasion, dirt, and other contaminants. This protection significantly reduces the risk of damage, thereby extending the lifespan of the cables.

2. Organization Enclosed cable carriers help in keeping cables and hoses neatly arranged. This organization minimizes the risk of tangled lines, which can lead to operational inefficiencies or costly downtime due to maintenance or repairs.

3. Flexibility The design of cable carriers allows for a high degree of flexibility concerning bending radius and mounting positions. This versatility is essential for dynamic applications like CNC machinery, robotics, and conveyor systems, where movement and flexibility are critical.

enclosed cable carrier

4. Ease of Maintenance With enclosed cable carriers, the removal and replacement of cables are simplified. This design feature allows technicians to easily access and service cables without disrupting the entire system. Consequently, maintenance becomes quicker and less labor-intensive.

5. Safety By reducing the risk of slack cables and potential tripping hazards, enclosed cable carriers enhance workplace safety. A well-organized system contributes to a clean and hazard-free environment.

Applications of Enclosed Cable Carriers

Enclosed cable carriers find applications across various industries. In manufacturing, they are widely used with CNC machines, robotic arms, and automated assembly lines. They are also prevalent in the aerospace sector, ensuring the secure transmission of power and data through moving components. In the automotive industry, enclosed cable carriers are utilized in conveyor systems and tooling applications.

Moreover, the entertainment industry employs these carriers in theme parks and theaters to manage complex lighting and audio systems. Likewise, enclosed cable carriers are increasingly integral to wind turbine and renewable energy setups, where they facilitate the movement of cables within rotating components.

Conclusion

In summary, enclosed cable carriers are vital components of modern machinery, enhancing the organization, protection, and movement of critical electrical and fluid lines. Their benefits, such as reducing wear and tear and improving safety and maintenance efficiency, highlight their indispensable role in various industrial applications. As technology advances, the importance of reliable and effective cable management solutions like enclosed cable carriers will continue to grow, driving innovation and operational excellence across multiple sectors. Investing in the right enclosed cable carrier system can yield significant long-term benefits and contribute to the overall success of industrial operations.