Alternative Solutions for Cable Management in Industrial Environments Using Cable Carriers

Understanding Enclosed Cable Carriers An Essential Component in Modern Machinery

In today’s fast-paced industrial world, efficient machinery operation is paramount to maintaining productivity and safety. One of the innovations that play a crucial role in this field is the enclosed cable carrier. These carriers are engineered to protect and organize cables, hoses, and other essential components in various applications, from heavy machinery to robotics and entertainment systems. This article explores the various types, benefits, and applications of enclosed cable carriers, showcasing their importance in contemporary industries.

What is an Enclosed Cable Carrier?

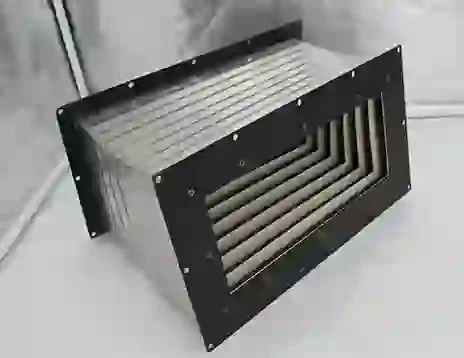

An enclosed cable carrier, also known as a drag chain or energy chain, is a system designed to guide and protect moving cables, hoses, and other flexible elements. They are typically constructed from high-quality plastics or metals, imparting durability and flexibility while maintaining lightweight characteristics. The “enclosed” nature of these carriers prevents contaminants like dust, debris, and moisture from compromising the integrity of the cables within, ensuring reliable operation and longevity.

Types of Enclosed Cable Carriers

Enclosed cable carriers come in various types, tailored for specific applications and environments. Some common varieties include

1. Straight Cable Carriers These are used in linear applications where motion is predominantly straight. They feature a uniform channel for cable accommodation and are easy to install.

2. Curved Cable Carriers Specifically designed for systems that require movement in a circular or arc shape. These carriers are ideal for robotic arms or similar systems, allowing for smooth movement along curved paths.

3. Modular Cable Carriers These can be customized with various components, allowing for specific cable arrangements catered to unique machinery requirements. This adaptability makes them prevalent in bespoke industrial applications.

4. Heavy-Duty Cable Carriers Built for extreme conditions, these carriers are commonly used in the mining, construction, and heavy manufacturing sectors. Their robust design can withstand high wear and tear, making them indispensable in demanding environments.

Benefits of Using Enclosed Cable Carriers

The adoption of enclosed cable carriers in industrial applications provides numerous advantages

1. Protection The enclosed design safeguards cables and hoses from physical damage and environmental hazards. This protection significantly reduces the cost associated with cable replacements and system downtime.

enclosed cable carrier

2. Organization These carriers help keep cables organized and routed efficiently, preventing tangles and kinks that can impair functionality.

3. Flexibility Enclosed cable carriers are designed to accommodate movement in multiple directions, allowing for dynamic applications such as robotic movements or automated conveyor systems.

5. Aesthetic Appeal In applications where visual appearance is critical, such as in entertainment systems or visual displays, enclosed cable carriers offer a clean and organized look that contributes positively to the overall design.

Applications of Enclosed Cable Carriers

Enclosed cable carriers are employed in a wide range of industries. They are commonly found in

- Manufacturing Used in CNC machines and assembly lines to protect power cables and hoses while allowing freedom of movement.

- Robotics Essential for robotic arms and automated systems, where precision and protection are critical for operational efficiency.

- Construction and Mining Heavy-duty cables are safely guided and protected, ensuring uninterrupted operation in harsh environments.

- Entertainment In concert and theater setups, these carriers organize cables for lighting and sound equipment, enhancing both safety and aesthetics.

- Automotive Used within car assembly lines and robotics to manage several cables effectively, ensuring seamless operations without tangling.

Conclusion

Enclosed cable carriers are invaluable components within modern machinery that contribute significantly to efficiency, safety, and organization. Their diverse applications across various industries underscore their versatility and importance in today's fast-evolving technological landscape. As industries continue to innovate and evolve, the demand for such protective and organizational systems will undoubtedly grow, making enclosed cable carriers a critical consideration for manufacturers and engineers alike.