Innovative Electrical Loom Tube Solutions for Efficient Wire Management and Organization

Understanding Electrical Loom Tubes An Essential Component in Wiring Systems

In the world of electrical engineering and wiring, efficiency, safety, and organization are paramount. Among the many components that play a critical role in achieving these goals, electrical loom tubes stand out as an important solution for protecting and organizing wires. This article delves into the significance of electrical loom tubes, their applications, benefits, and considerations for selecting the right type for various projects.

What are Electrical Loom Tubes?

Electrical loom tubes, often referred to as loom tubing or wire loom, are flexible, protective conduits designed to house and manage electrical wires and cables. These tubes are typically made from materials such as nylon, polyethylene, or other plastics, offering excellent protection against abrasion, chemicals, and environmental factors. Electrical loom tubes come in various diameters and lengths, making them suitable for a wide range of applications in automotive, industrial, and consumer electronics.

Applications of Electrical Loom Tubes

1. Automotive Wiring One of the most prominent uses of electrical loom tubes is in the automotive industry. Loom tubing protects wiring harnesses from heat, moisture, and mechanical damage, ensuring the longevity and reliability of vehicle electrical systems.

2. Industrial Equipment In manufacturing and industrial settings, loom tubes are used to organize and protect wiring in machinery. This not only minimizes the risk of short circuits and damage but also facilitates easier maintenance and troubleshooting.

3. Consumer Electronics From household appliances to personal electronics, loom tubing is utilized to manage wires, helping to maintain a clean aesthetic while preventing cable wear.

Benefits of Electrical Loom Tubes

- Protection The primary function of electrical loom tubes is to shield wires from various environmental hazards. They provide resistance to abrasion, chemicals, and UV radiation, making them ideal for both indoor and outdoor applications.

- Organization Loom tubes help keep wires and cables neatly organized, reducing clutter and making it easier to trace circuits during installation or repairs. This organization can save time and effort during maintenance or troubleshooting.

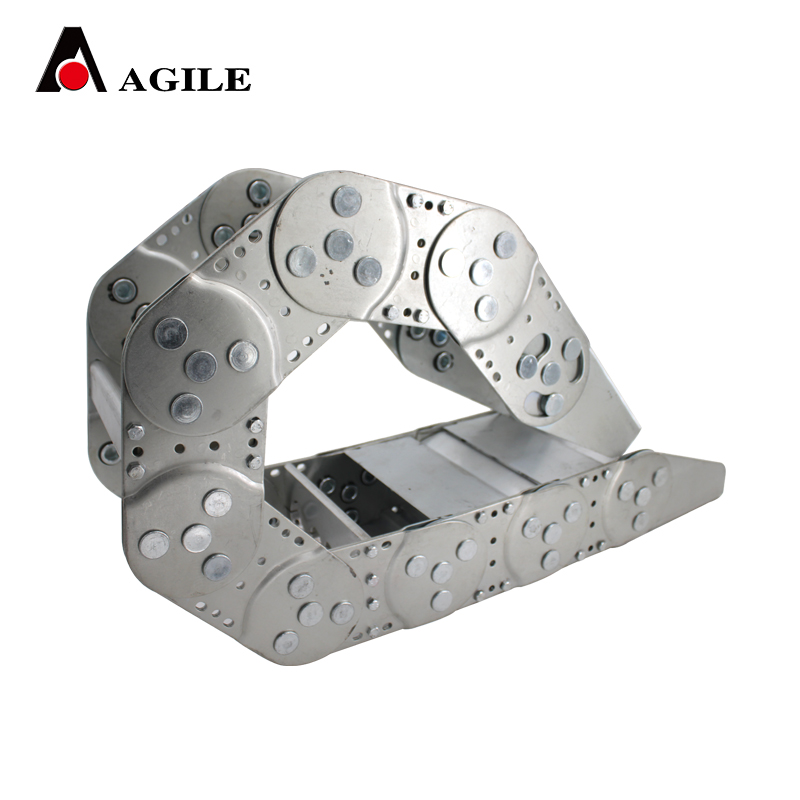

electrical loom tube

- Flexibility Many loom tubes are designed to be flexible, allowing them to bend and fit into various spaces without losing their protective properties. This adaptability makes them suitable for complex wiring layouts.

- Heat Resistance Electrical loom tubes are often engineered to withstand high temperatures, making them suitable for applications where heat may be a concern, such as engine compartments in vehicles.

- Aesthetic Appeal By using loom tubes, one can create a clean and professional appearance in any wiring project. This visual aspect is particularly important in consumer electronics and automotive interiors.

Considerations for Selecting Loom Tubes

When choosing the right electrical loom tube, it’s essential to consider several factors

1. Material Different applications may require different materials. For instance, nylon tubing offers great flexibility and resistance to chemicals, while polyethylene is robust and ideal for more demanding conditions.

2. Diameter and Length The diameter of the loom tube should match the size of the bundled wires it will contain. Too tight a fit can damage the wires, while too loose a fit can lead to disorganization.

3. Temperature Rating Evaluate the temperature conditions the wires will be exposed to. Ensure the selected loom tube has a suitable temperature rating to prevent degradation over time.

4. Color Coding In complex wiring systems, color-coded loom tubes can facilitate easy identification of different circuits.

5. Installation Method Some loom tubes are designed for ease of installation, featuring adhesive backing or snap-on designs. Consider the installation method that will best suit your project needs.

Conclusion

Electrical loom tubes are an indispensable component in the organization and protection of wiring systems across various industries. Their ability to enhance safety, prolong the life of cables, and improve aesthetic appearance makes them a worthwhile investment in any electrical project. By understanding the different types of loom tubes available and their specific applications, engineers and DIY enthusiasts alike can make informed decisions that lead to more efficient and safe electrical installations.