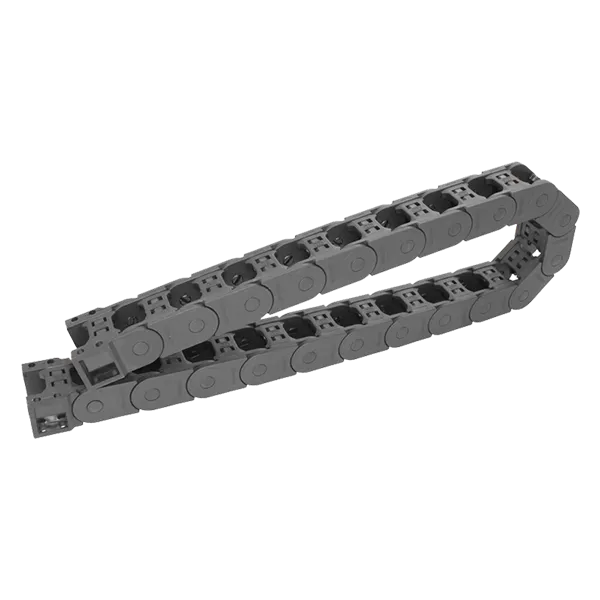

electrical cable carrier

Navigating the complex world of electrical cable carriers requires a deep understanding of their functionality, design intricacies, and applications. These carriers, often overlooked yet quintessential, play a pivotal role in safeguarding and managing cables in dynamic applications. Given their critical function, choosing the right electrical cable carrier can significantly enhance the efficiency and longevity of electrical systems, particularly in industrial settings.

One cannot discuss electrical cable carriers without highlighting their impact on system efficiency. By organizing cables neatly within a dedicated pathway, cable carriers help in avoiding tangling and physical wear, thereby reducing maintenance costs and downtime. Rapid advances in design technology have also led to innovations in modularity, allowing for easy replacement or extension of carrier systems as machinery requirements grow. Authoritative insights from industry leaders emphasize the importance of routine maintenance and inspection of cable carrier systems. Ensuring that these components are free from debris and environmental damage goes a long way in maintaining the integrity of the electrical systems they support. Trustworthiness in cable carrier systems also emerges from adherence to rigorous industrial standards and certifications. Opting for carriers that meet international standards such as ISO is a testament to their quality and reliability. This accreditation assures users of the carrier’s performance capabilities and safety in critical operations. In essence, the expertise involved in selecting and maintaining electrical cable carriers is non-trivial, requiring a balanced appreciation of technical specifications, operational environments, and industry standards. By leveraging insightful experiences and authoritative guidelines, businesses can enhance their operational efficiency and system reliability. Thus, investing time into understanding and optimizing cable carrier choices reflects a strategic commitment to excellence in the industrial realm.

One cannot discuss electrical cable carriers without highlighting their impact on system efficiency. By organizing cables neatly within a dedicated pathway, cable carriers help in avoiding tangling and physical wear, thereby reducing maintenance costs and downtime. Rapid advances in design technology have also led to innovations in modularity, allowing for easy replacement or extension of carrier systems as machinery requirements grow. Authoritative insights from industry leaders emphasize the importance of routine maintenance and inspection of cable carrier systems. Ensuring that these components are free from debris and environmental damage goes a long way in maintaining the integrity of the electrical systems they support. Trustworthiness in cable carrier systems also emerges from adherence to rigorous industrial standards and certifications. Opting for carriers that meet international standards such as ISO is a testament to their quality and reliability. This accreditation assures users of the carrier’s performance capabilities and safety in critical operations. In essence, the expertise involved in selecting and maintaining electrical cable carriers is non-trivial, requiring a balanced appreciation of technical specifications, operational environments, and industry standards. By leveraging insightful experiences and authoritative guidelines, businesses can enhance their operational efficiency and system reliability. Thus, investing time into understanding and optimizing cable carrier choices reflects a strategic commitment to excellence in the industrial realm.