Effective Protection Solutions for CNC Machines with High-Quality Bellow Covers and Accessories

Understanding CNC Machine Bellow Covers Importance and Benefits

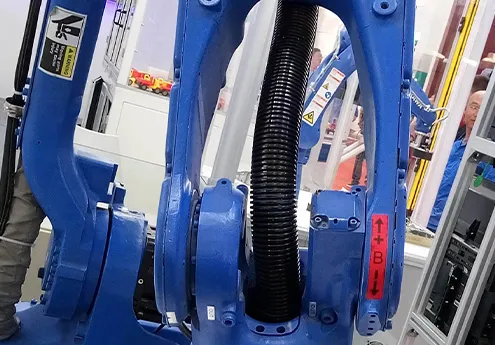

In the realm of precision manufacturing, the use of CNC (Computer Numerical Control) machines has revolutionized how components are fabricated and assembled. One critical aspect that often doesn’t get the attention it deserves is the protection provided by bellow covers. These protective elements are essential for the long-term functionality and precision of CNC machines.

What are CNC Machine Bellow Covers?

CNC machine bellow covers, commonly referred to simply as bellow covers, are flexible, protective casings that shield the various components of CNC machines from debris, coolant, dust, and other harmful materials. They are typically made from high-quality materials such as neoprene, rubber, or polyurethane, which combine durability with flexibility. Bellow covers are commonly used in applications involving linear motion systems, such as CNC mills, lathes, and routers, where precision and cleanliness are paramount.

The Importance of Bellow Covers

1. Protection from Contamination One of the primary functions of bellow covers is to protect sensitive components from contaminants. CNC machines are often used in environments where metal shavings, dust, and fluids are prevalent. Bellow covers safeguard guideways, ball screws, and linear rails by preventing these contaminants from entering sensitive areas, which can lead to wear, corrosion, and even failure of components.

2. Maintenance Reduction By protecting machine parts from contaminants, bellow covers also reduce the need for frequent maintenance. Less wear and tear translate to fewer breakdowns and less downtime, which is crucial in maintaining productivity in manufacturing environments. Operators save time and resources by minimizing the frequency of inspections and repairs.

cnc machine bellow covers

3. Enhanced Precision CNC machines are designed to achieve high levels of accuracy in their operations. If parts are compromised by debris or wear, the precision of machining processes can suffer. Bellow covers ensure that components operate smoothly without unnecessary friction or misalignment, thus maintaining the machine's precision and output quality.

4. Extended Lifespan of Components By shielding crucial components from the harsh operating environment, bellow covers can significantly extend the lifespan of CNC machinery. When parts are kept clean and free from damage, the overall investment in the machine is protected, allowing manufacturers to achieve better returns over time.

Materials and Design Choices

The effectiveness of bellow covers largely depends on their material and design. Neoprene and rubber are popular choices due to their elasticity and resistance to abrasion, while polyurethane offers additional benefits like chemical resistance and durability. The design of the bellow covers can vary, with options ranging from lightweight single-layer designs to robust multi-layer constructions for extra protection.

Customization is also a vital aspect. Manufacturers can design bellow covers to fit specific CNC machine models, ensuring a snug fit that maximizes protective capabilities. Furthermore, bellow covers can be tailored to withstand various working conditions, including extreme temperatures and exposure to chemicals.

Conclusion

In conclusion, CNC machine bellow covers play a vital role in ensuring the reliable operation of precision machinery. Their protective qualities not only safeguard against contaminants but also contribute to reduced maintenance needs, enhanced operational precision, and extended lifespan of components. As manufacturers continue to seek ways to optimize productivity and minimize costs, investing in high-quality bellow covers for CNC machines is a decision that pays dividends in the long run. By providing this critical layer of protection, bellow covers help keep CNC machines running at peak performance, ultimately supporting the overall efficiency of manufacturing processes.