Flexible e-chain Cable Carrier Solutions for Efficient Energy and Data Transmission in Industrial Applications

Understanding E-Chain Cable Carriers An Essential Component in Modern Engineering

In the realm of modern engineering and manufacturing, the efficient management of electrical and data cables is paramount. One innovative solution that has gained significant traction in various industries is the e-chain cable carrier. This dynamic system of moving cables plays a crucial role in ensuring that essential electrical connections remain intact, safe, and organized, particularly in high-motion applications.

What is an E-Chain Cable Carrier?

An e-chain, or energy chain, is a flexible cable carrier that provides protection and mobility for electrical, data, and fluid lines. Designed to move along with machinery while keeping cables secure, the e-chain can be seen in diverse applications—ranging from robotics and CNC machines to conveyors and automated manufacturing systems. By containing and managing cables within a structured system, e-chains prevent wear and tear, reduce cable tangling, and promote a longer lifespan for electrical connections.

The Design and Functionality of E-Chains

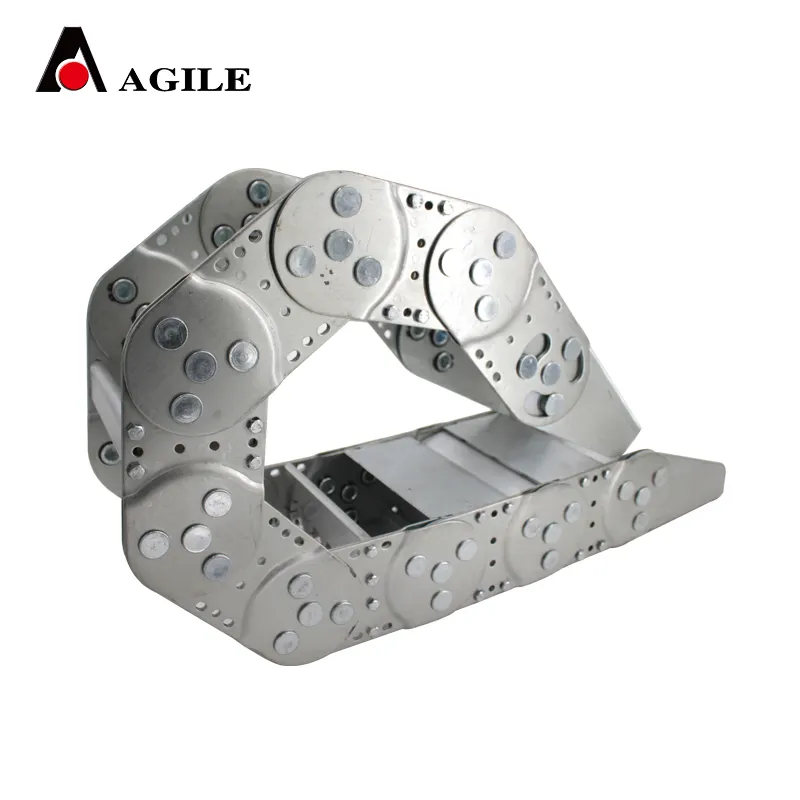

E-chains are constructed from durable plastic or metal and come in various designs to suit different application needs. The design typically includes a series of interconnected links or segments that form a chain-like structure. This structure allows for bending and flexing while maintaining the integrity of the cables inside. Some e-chains also feature an innovative divide between power and data cables, ensuring that interference is minimal and performance remains optimal.

The key function of e-chains is to guide and safeguard cables as they move with machinery. When a machine or tool operates, it often involves back-and-forth movements or rotations, which can place considerable stress on connecting cables. E-chains mitigate this issue by allowing cables to move freely within the carrier while protecting them from crushing, abrasion, and repetitive stress.

Applications and Industry Impact

E-chain cable carriers find their place in a variety of industries. In manufacturing environments, they are frequently used in automated assembly lines where robotic arms perform repetitive tasks. E-chains ensure that the necessary power and signal cables have the required slack while remaining organized and protected, ultimately increasing operational efficiency.

e chain cable carrier

In the realm of mobile equipment, such as cranes or lifts, e-chains are utilized to keep electrical and hydraulic lines secure during operation. Their ability to withstand harsh conditions makes them ideal for outdoor applications where exposure to elements is a concern.

Benefits of Using E-Chains

1. Efficiency By organizing cables effectively, e-chains reduce downtime caused by cable damage or entanglement, enhancing overall operational efficiency.

2. Durability Made from high-quality materials, e-chains are built to withstand wear and tear, making them a cost-effective investment for long-term use.

3. Customizability Various sizes and configurations of e-chains allow for customization to meet specific application requirements, making them versatile in nature.

4. Safety With their protective design, e-chains help to prevent electrical shorts and other hazards associated with degraded cables, ensuring a safer working environment.

Conclusion

In conclusion, e-chain cable carriers are indispensable components in modern engineering, offering a sophisticated solution for managing cables in dynamic environments. Their robust design, adaptability, and ability to enhance operational efficiency make them a preferred choice across industries. As technology continues to advance and machinery becomes more complex, the role of e-chains is likely to expand, further solidifying their importance in the safe and effective operation of equipment and systems. Investing in quality e-chain solutions not only safeguards equipment but also supports the seamless integration of movement and connectivity in the increasingly automated world of manufacturing and engineering.