Durable Wire Loom for Enhanced Protection and Organization of Electrical Cables

The Importance of Protective Wire Loom in Electrical Projects

In the realm of electrical installations and automotive applications, one often overlooked component is the protective wire loom. While the primary focus typically lies on the quality of wires and connections, protective wire looms play a crucial role in enhancing the longevity and safety of electrical systems. This article will explore what protective wire looms are, their benefits, and applications, and why every electrical project should consider their use.

What is Protective Wire Loom?

Protective wire loom, often referred to as wire loom tubing, is a flexible, protective covering designed to safeguard electrical wires and cables from physical damage, abrasion, moisture, and other environmental factors. Typically made from materials such as polyethylene, nylon, or PVC, wire looms are engineered to withstand various conditions, making them suitable for different applications, from automotive wiring to industrial machinery.

Benefits of Using Protective Wire Looms

1. Enhanced Durability One of the key advantages of protective wire looms is their ability to enhance the durability of electrical wiring. By shielding wires from abrasion and external stressors, wire looms can significantly reduce wear and tear, thereby extending the life of the wires within the loom.

2. Organized Wiring Wire looms assist in keeping wiring systems organized. In complex electrical systems, it’s easy for wires to become tangled or confused. By bundling wires together in a protective loom, technicians can maintain an organized setup that is easier to manage and troubleshoot.

3. Moisture and Chemical Resistance Many protective wire looms are designed to resist moisture and various chemicals, which makes them ideal for use in environments where wires may be exposed to liquids or corrosive substances. This protective feature helps to prevent short circuits and other electrical failures caused by environmental elements.

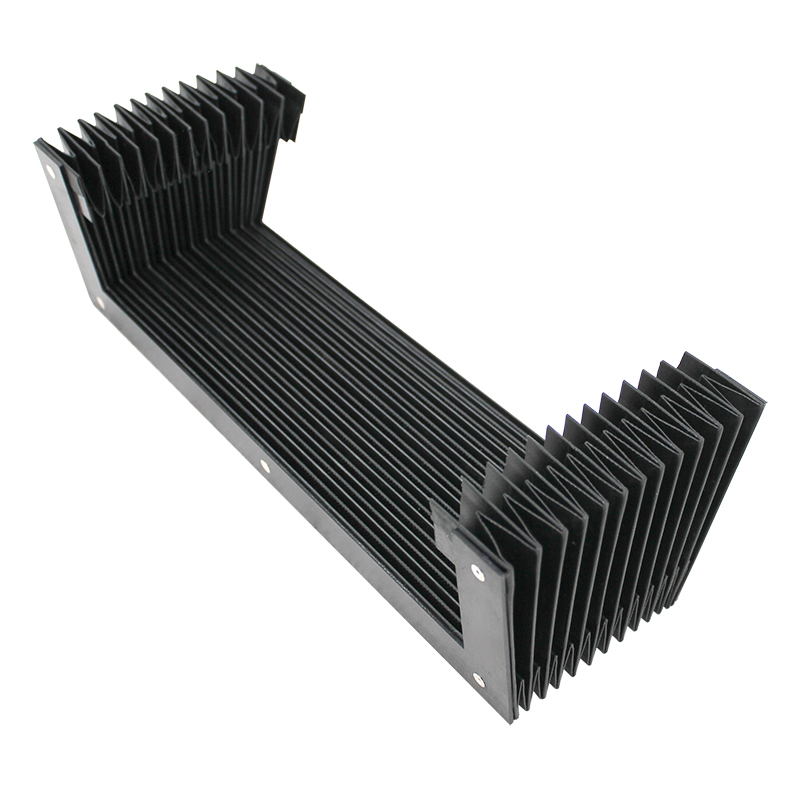

protective wire loom

4. Heat Resistance Certain wire looms are manufactured to withstand high temperatures, making them suitable for automotive applications where heat can be a significant factor. By using heat-resistant materials, these looms contribute to the safe operation of electrical systems, particularly in engine compartments where temperatures can soar.

5. Aesthetics In addition to functionality, protective wire looms can also enhance the visual appeal of electrical installations. They provide a clean and professional appearance, which can be particularly important in automotive and custom installations.

Applications of Protective Wire Loom

Protective wire looms find their application across a broad spectrum of industries. In the automotive industry, they are commonly used to protect wiring harnesses in vehicles, ensuring that vital electrical connections are safeguarded against the rigors of the road. In industrial settings, looms can encapsulate wiring for machinery, protecting them from dust, moisture, and potential mechanical damage.

Furthermore, in residential and commercial electrical systems, protective wire looms can be utilized to organize and protect home wiring, providing peace of mind to homeowners about the safety and longevity of their electrical systems.

Conclusion

In conclusion, protective wire looms are an indispensable component in any electrical project, offering a wide range of benefits, including increased durability, organization, and protection from environmental factors. As the demand for reliability and efficiency in electrical systems continues to grow, the inclusion of protective wire looms will undoubtedly play a critical role in ensuring that wiring remains safe and functional. Whether for automotive, industrial, or residential applications, investing in quality protective wire looms is a step toward creating a safer and more reliable electrical environment.