Durable Heat Resistant Split Loom Tubing for Enhanced Protection and Organization of Wires and Cables

The Importance of Heat Resistant Split Loom in Modern Applications

In today's fast-paced industrial landscape, the significance of protection and efficiency in electrical wiring cannot be overstated. Among the various protective solutions available, heat resistant split loom has emerged as a vital component in safeguarding cables and wires across numerous applications. This article explores the features, benefits, and applications of heat resistant split loom, demonstrating its importance in ensuring safety and functionality.

Understanding Heat Resistant Split Loom

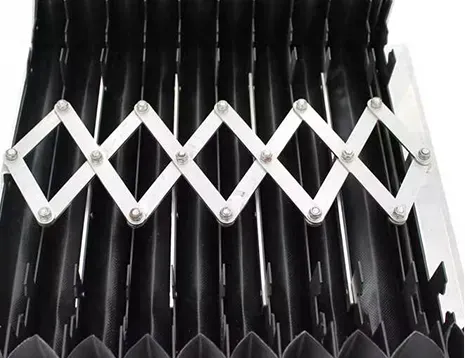

Heat resistant split loom is a type of tubular casing designed to protect electrical wires and cables from heat, abrasions, and environmental factors. Made from durable, heat-resistant materials—often polyethylene or nylon—this split loom offers a split design that allows easy insertion of cables while maintaining robust protection. The heat resistance aspect ensures that the split loom can withstand elevated temperatures without degrading, making it suitable for use in environments where heat exposure is prevalent.

Key Benefits

1. Protection from Heat Exposure One of the most significant advantages of using heat resistant split loom is its ability to withstand high temperatures. In various industries, electrical components are often subjected to extreme heat, whether from motors, engines, or ambient conditions. This protective covering not only shields the wires from potential thermal damage but also enhances their longevity.

heat resistant split loom

2. Durability Against Physical Damage The split loom acts as a protective barrier against abrasion, cuts, and impacts. This durability is particularly crucial in heavy machinery and automotive applications, where cables may be exposed to rough handling and movement. By preventing wear and tear, heat resistant split loom extends the life of electrical systems.

3. Ease of Installation The split design of this loom allows for quick and easy installation. Electricians and technicians can effortlessly insert cables without requiring additional tools or dismantling existing setups. This ease of use reduces installation time, translating into cost savings for businesses.

4. Versatile Applications Heat resistant split loom can be found in a wide range of applications. It is extensively used in automotive wiring harnesses, industrial machinery, HVAC systems, and even consumer electronics. Its versatility makes it an essential component across various sectors, including manufacturing, automotive, aerospace, and telecommunications.

5. Environmental Resistance Beyond heat, this casing offers resistance to moisture, chemicals, and UV exposure. This characteristic is vital in outdoor applications where cables may face harsh environmental conditions. The added protection ensures that electrical systems remain operational even in challenging settings.

Conclusion

In conclusion, heat resistant split loom is a crucial innovation in cable management and protection. Its ability to withstand high temperatures, alongside its durability and ease of installation, makes it an indispensable tool for industries aiming to enhance the safety and longevity of electrical wiring. As technology continues to evolve, and with the increasing complexity of electrical systems, the relevance of heat resistant split loom will only grow. By investing in quality protective solutions like this, companies can not only safeguard their investments in infrastructure but also ensure the safety of their operations and personnel. In a world where efficiency and safety go hand in hand, the significance of heat resistant split loom stands tall as a pillar of modern electrical management.